Full-automatic mechanical walnut shell opening machine

A walnut and scribing technology, which is applied in the field of automatic mechanical walnut scribing machines, achieves the effects of high intelligence, improved shell breaking rate, and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

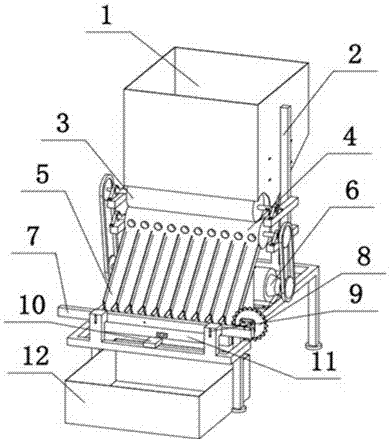

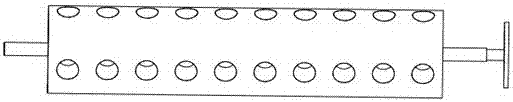

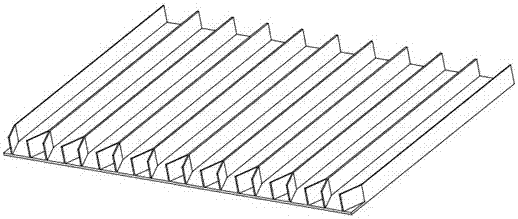

[0014] Embodiment 1: refer to figure 1 , figure 2 , image 3 , the present invention relates to a fully automatic walnut scoring machine, characterized in that it includes a feeding hopper (1), a frame (2), a bristle brush roller (3), a guide roller (4), and a sorting slideway ( 5), mechanical automatic scribing device and storage box (12), etc.; wherein the mechanical automatic scribing device includes: electric cylinder (7), cutting saw blade (8), walnut clamp (11), cylinder (10), etc.; The bottom outlet of the feeding hopper is located between the bristle brush roller (3) and the guide roller (4); the PLC controls the rotation of the deceleration motor (6), and the motor drives the bristle brush roller (3) and the guide roller (4) through the chain Rotate; the bristle brush roller (3) is close to the guide roller (4), and the bristle brush roller (3) brushes the walnuts into the guide holes of the guide roller (4) and prevents the walnuts from falling between the two rol...

Embodiment 2

[0015] Embodiment 2: Compared with Embodiment 1, the difference of this embodiment is that the thickness of the cutting saw blade is different. In order to adapt to the width of the scribe, it can be replaced with a 2.3mm thick cutting saw blade.

Embodiment 3

[0016] Embodiment 3: The difference between this example and Embodiment 1 is that the distance between the sorting chute baffles is widened, and the distance between the sorting chute baffles is widened by adjusting the position of the fixing nut. 52mm, the distance between the baffles at the bottom of the slideway is widened to 47mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com