Field corn straw in-situ silage quantitative block processing and production device

A corn stalk and silage technology, which is applied in the field of feed science, can solve the problems of polluting the atmospheric environment, ineffective utilization of stalks, and excessive waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

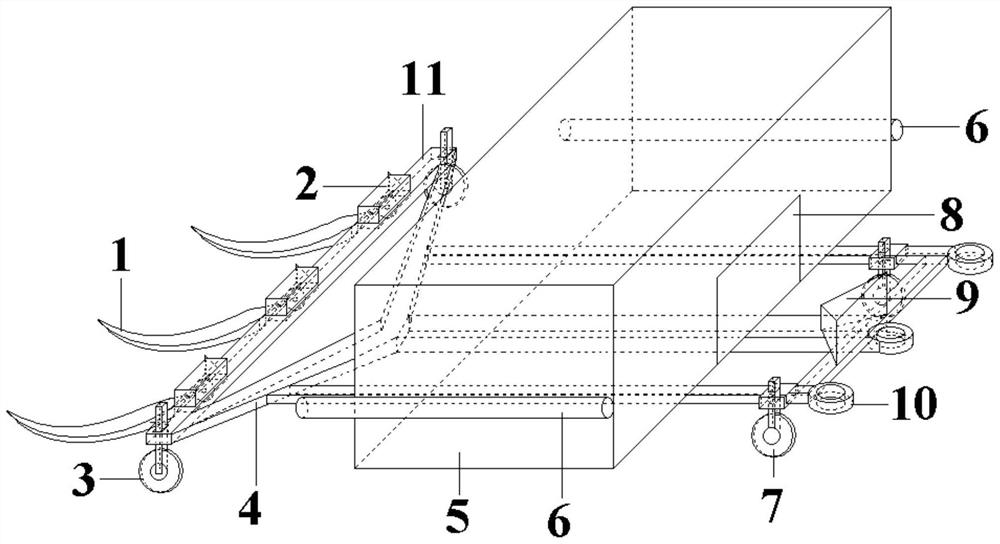

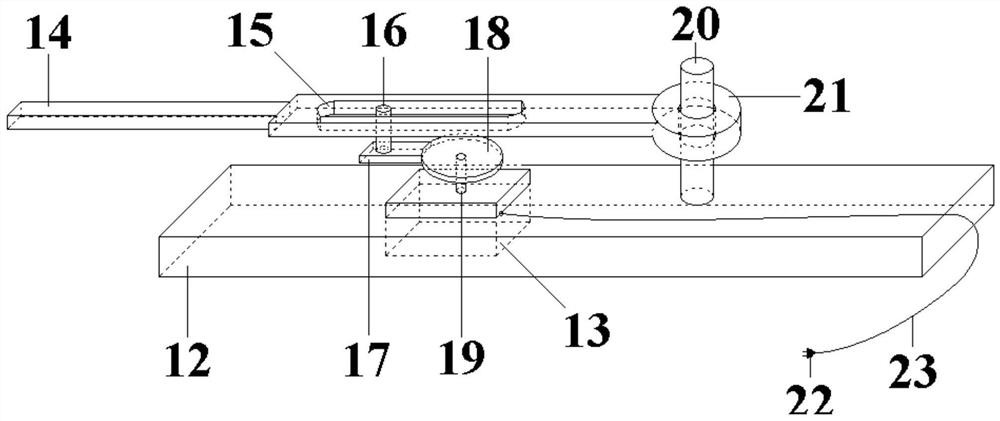

[0016]As shown in the figure, the device for processing quantitative blocks of in-situ corn stalk silage in the present invention consists of a gathering claw 1, a cutting machine 2, a support wheel 3, a support frame 4, a crushing processor 5, a stalk receiving rod 6, and a support wheel 7. Bag outlet 8, top drop block 9, online ring 10, cutting frame 11, stalk receiving rod body 12, stalk receiving rod motor 13, swing rod 14, swing groove 15, swing shaft 16, swing disc protrusion 17, swing Disc 18, motor rotor 19 for the stalk retracting rod, fixed shaft 20, swing ring 21, plug 22 for the power cord of the stalk retracting rod motor, 23 for the power cord of the stalk retracting rod motor, traction ring 24, traction rod 25, slide rail 26, and trailer 27 , bag forming frame 28, material collecting hole 29, slide rail groove 30, bagging processing chamber 31, crushing motor support table 32, air extraction forming device 33, spray head 34, fermentation liquid tank 35, aggregate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com