Loudspeaker drum paper, preparation method thereof and loudspeaker comprising the same

A speaker and drum paper technology, applied in the field of speakers, can solve the problems of low yield of drum paper, single color of medium drum paper, high production cost, etc., and achieve the effect of low production cost, short cycle and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the drum paper provided by the invention can coat the surface of carcasses of various colors with pigment coatings, so as to obtain the drum paper with required pigments. The production cost is low, the cycle is short, simple and easy, and suitable for large-scale production.

[0035] It can be understood that the carcass in the present invention can be black or other colors. In order to reduce production costs, the carcass can be selected as black carcass.

[0036] In some embodiments of the present invention, the pigment coating includes a color layer composed of any one or at least two of white, yellow, blue, green or pink; preferably a white coating.

[0037] Drum paper with different pigments can be obtained by selecting paints of different colors to make the pigment coating.

[0038] In some embodiments of the invention, the carcass is a paper carcass. Paper carcasses are lightweight, sensitive and low cost.

[0039] In some embodimen...

Embodiment 1

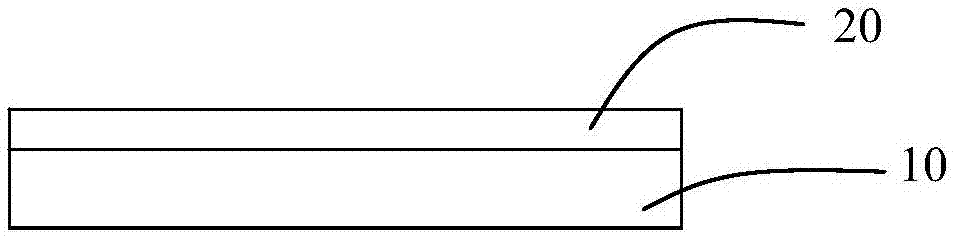

[0070] Such as figure 1 As shown, the present embodiment is a speaker drum paper, which includes a body 10, and the surface of the body 10 is coated with a pigment coating 20.

[0071] Wherein, the carcass 10 is a carcass made of paper, the pigment coating 20 is a white coating, and the thickness of the white coating is 25 microns. Carcass 20 edge is provided with the drum paper limit of rubber material.

[0072] The preparation method of the drum paper for loudspeaker in this embodiment is as follows: first prepare a carcass with a black pulp with a beating degree of 19°SR, and then coat a white coating on the surface of the black carcass to obtain the drum paper for a speaker. Wherein, the drum paper for the loudspeaker is obtained by drying after coating the white coating on the surface of the carcass, the drying temperature is 55° C., and the drying time is 20 minutes.

Embodiment 2

[0074] This embodiment is a kind of drum paper for a loudspeaker. The difference from Embodiment 1 is that the pigment coating in this embodiment is a light blue coating.

[0075] The preparation method of the speaker drum paper in this embodiment is as follows: first prepare a carcass with black pulp, and then apply a light blue coating on the surface of the black carcass to obtain the speaker drum paper.

[0076] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com