Burning verification method of electric quantity management and current monitoring IC of battery core

A technology of power management and current monitoring, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of large scalability and limitations, affecting the achievement of delivery, high cost expenditure, and improving programming efficiency. , the effect of avoiding storage time and saving calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

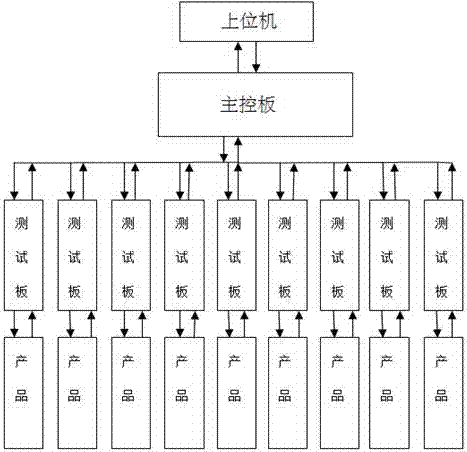

[0023] see figure 1 , a battery power management and current monitoring IC burning verification equipment, including the host computer, main control board, test board and test equipment (not shown in the figure); the host computer can be a commonly used computer, on the host computer ( The lower computer) is equipped with a master single-chip microcomputer, and a slave single-chip microcomputer is installed on the test board. The test equipment includes ammeter, voltmeter and other equipment, and the test equipment is connected to the test board.

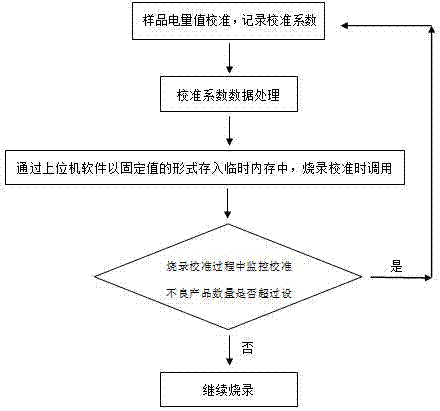

[0024] see figure 2 , a method for power management of a battery cell and a method for burning and verifying a current monitoring IC, including a method for burning battery information and a verification method, and the verification method includes a current verification method and a power verification method. The specific steps of the power verification method described above are as follows:

[0025] S1. According to the calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com