Self-dedusting hot blast stove

A hot blast stove and ash feeding technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of reducing work efficiency, time-consuming, health hazards of workers, etc., so as to improve work efficiency and reduce personnel. output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

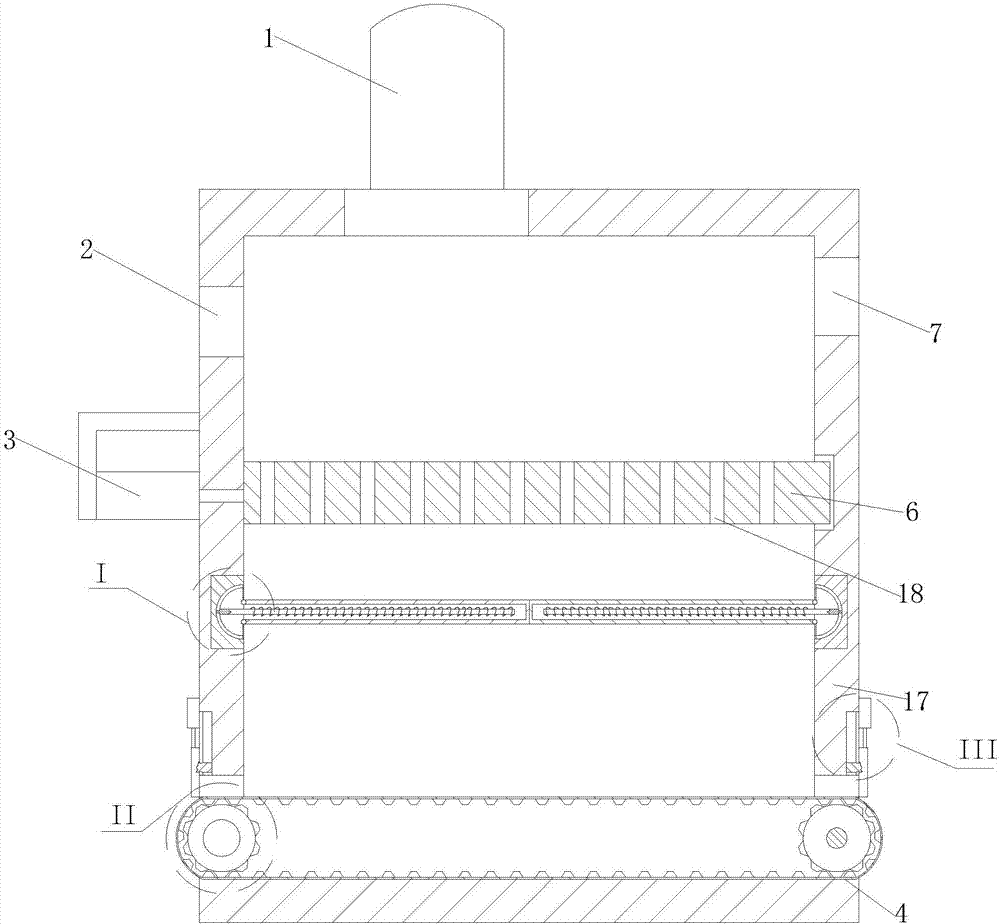

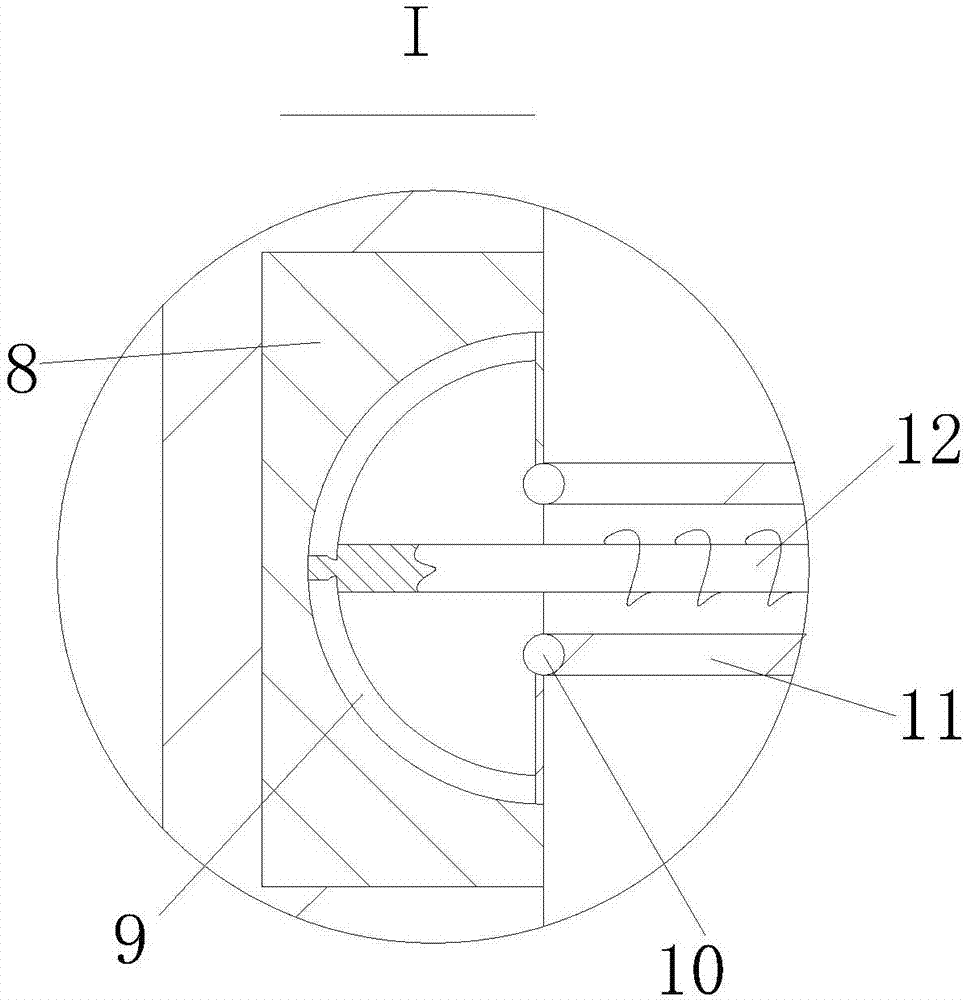

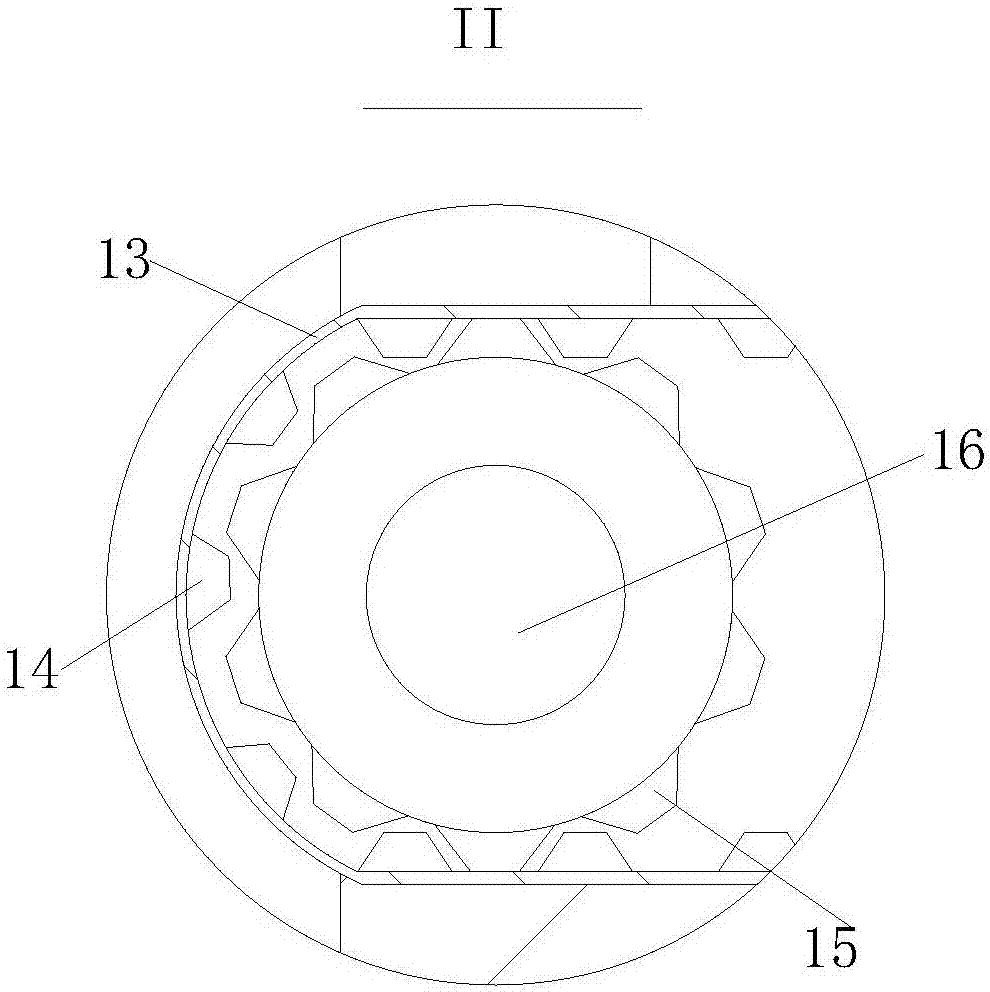

[0020] like Figure 1 to Figure 4 Shown, a kind of self-removing hot-blast stove comprises hot-blast stove 17, and the upper end of described hot-blast stove 17 is built-in the vibrating device that is used for shaking off coal ash, and the middle end of described hot-blast stove 17 is built-in for accumulating enough There is an elastic ash dumping device that can dump the coal ash by itself, and the lower end of the hot blast stove 17 is built-in with an ash removal device that can provide ventilation and transport the coal ash to the outside.

[0021] Described vibrating device is arranged on the upper end of hot blast stove 17 insides, is used for shaking off coal ash; Described elastic ash pouring device is arranged on the middle end of hot blast stove 17 insides, is used for pouri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com