Casting forming water cooled fire grate segment

A technology of water-cooled grate and casting molding, which is applied in the field of incineration, can solve the problems of inapplicability and limited cooling effect of air cooling, and achieve the effects of uniform cooling effect, reduced smoke emission and sufficient residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

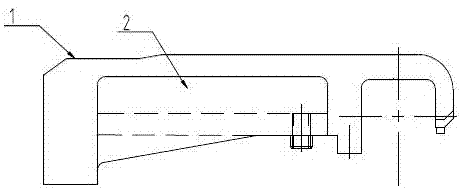

[0020] Such as figure 1 , figure 2 and image 3 As shown, the water-cooled grate body 1 is cast, and the internal water chamber 2 is cast. The bottom of the grate is cast with water inlet and outlet, and the water inlet joint 3 and the water outlet joint 4 are welded. The inner water chamber is cast with guide ribs plate 5. During operation, water is supplied by the circulating cooling water system, and the water pipe is connected to the water inlet joint 3 and the water outlet joint 4. The water flows in from the water inlet, passes through the U-shaped internal water cavity 2 in the grate, and flows out from the water outlet, and is heated by heat convection. Water-cooled grate pieces for cooling. The movable beams and fixed beams of the entire grate frame are arranged alternately, and water-cooled grate pieces 102 with thermocouples can be evenly arranged on the fixed grate beams as required, and the rest are standard water-cooled grate pieces 101, such as Figure 4 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com