Novel high-lift built-in type submerged pump

A high-lift, submersible pump technology, applied in the direction of non-variable pumps, pumps, pump devices, etc., can solve the problems of high external water pressure of the motor, impeller stuck, gravity eccentricity of the machine barrel, etc., to ensure the performance and guarantee The effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

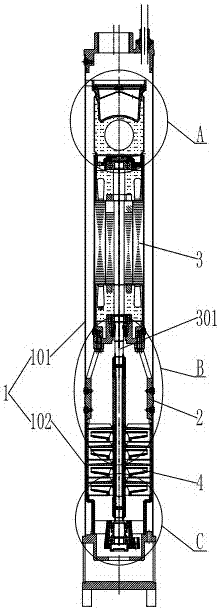

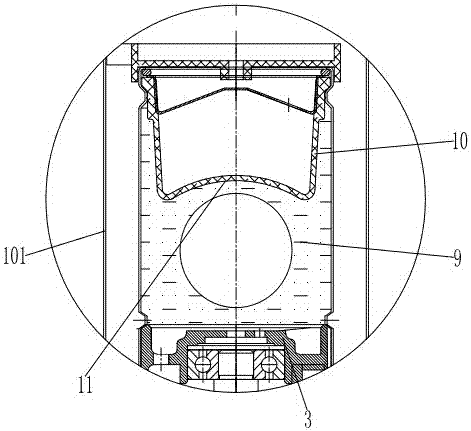

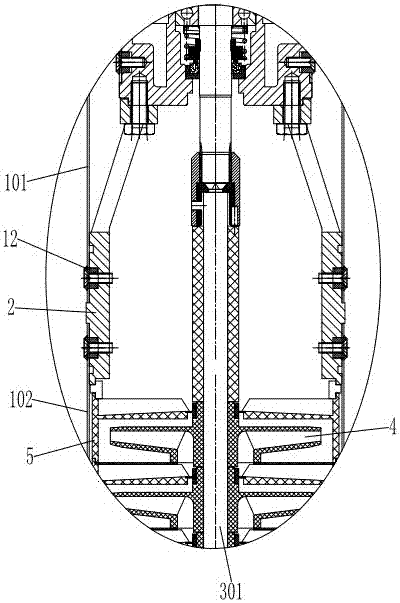

[0020] see Figure 1 to Figure 4 , the present invention provides a new type of high-lift built-in submersible pump, including a barrel 1, the barrel is composed of an upper steel pipe 101 and a lower steel pipe 102, and the upper steel pipe 101 and the lower steel pipe 102 are connected by a connecting pipe 2; A motor 3 is fixed inside the above steel pipe 101; the motor 3 is connected with several stages of impellers 4 through its own motor shaft 301, and the impellers 4 are located in the lower steel pipe 102; the outer casing of the impeller 4 is provided with an impeller barrel 5; A fixing frame 6 is fixed inside the lower end; the adjusting part 7 is installed on the fixing frame 6; the free end of the motor shaft 301 of the motor 3 is connected with the adjusting part 7 through an angular contact ball bearing 8; Mechanical oil 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com