Connecting mechanism for corner of fabricated building and construction technology of connecting mechanism

A connection mechanism and assembly technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of long construction period, large manpower demand, high building construction cost, etc., and achieve the effect of preventing corrosion and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

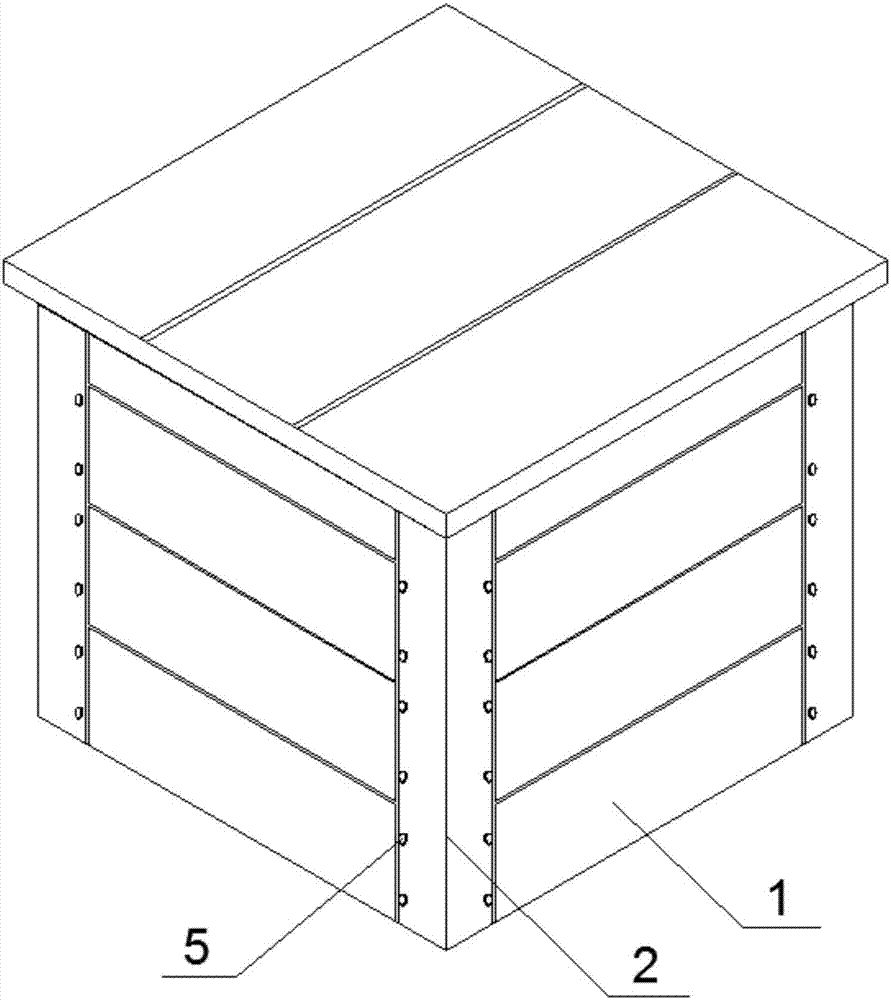

[0019] The present invention is a connection structure at the corner of a prefabricated house. The connection structure includes wall panels 1 on both sides and a support unit at the corner formed by the two sides. The outer side of the support unit is fixedly connected with a corner post 2, which is a right-angle shape. Ensure that the appearance of the house is beautiful without affecting the stability and safety of the house.

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

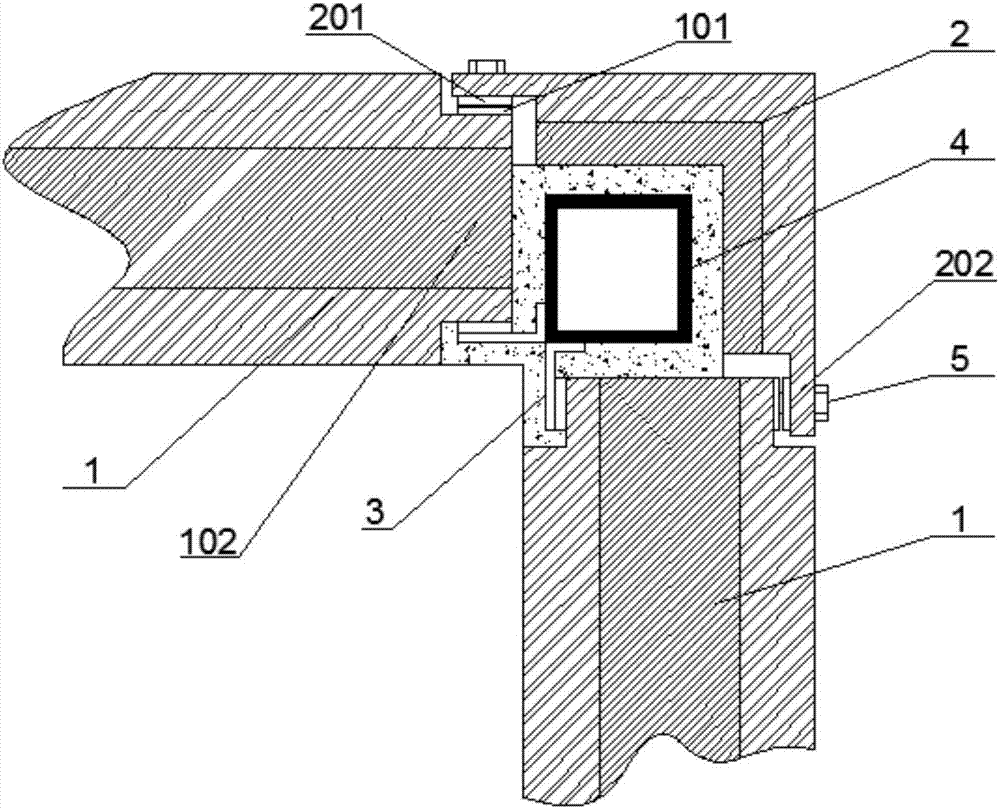

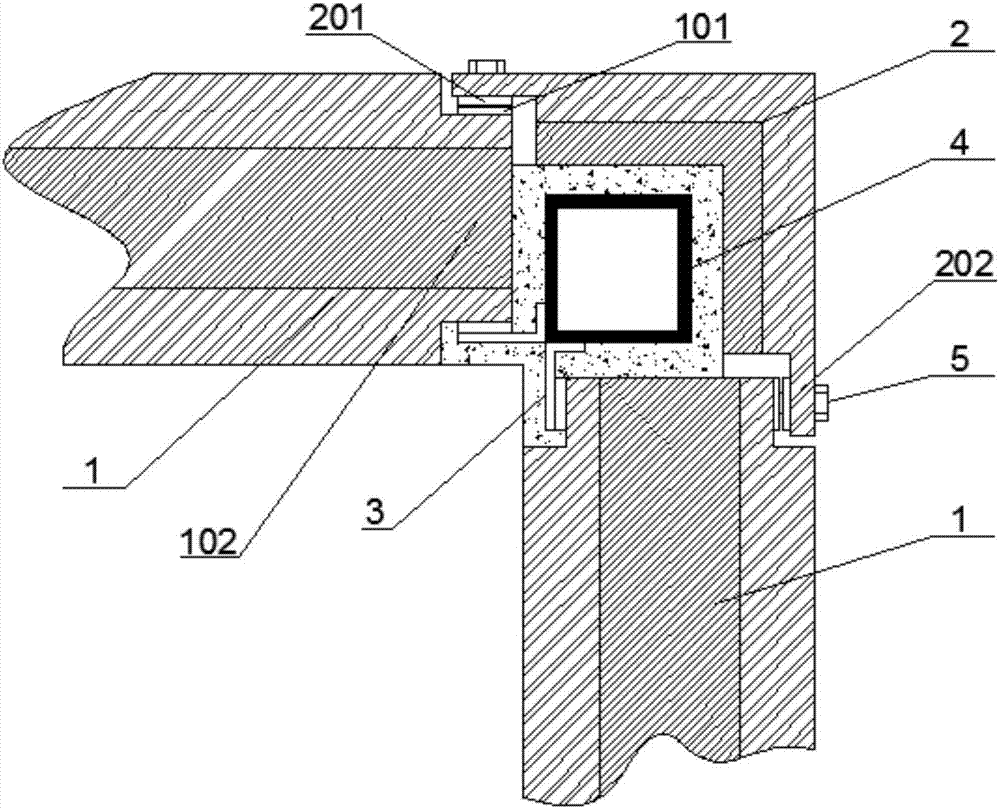

[0021] Specific examples, such as figure 1 and figure 2 as shown,

[0022] The wallboard 1 and the corner post 2 are respectively provided with a first embedded iron plate 101 and a second embedded iron plate 201, and the first embedded iron plate 101 has outer connecting ends on both sides of the end of the wallboard 1 respectively. and the inner connection end, the second embedded iron plate 201 has exposed ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com