Tray mold capable of achieving injection molding of multiple bottom feet

A technology of feet and pallets, which is applied to household appliances, other household appliances, household components, etc., can solve the problem that the pallet mold can only produce one kind of pallet, and achieve the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

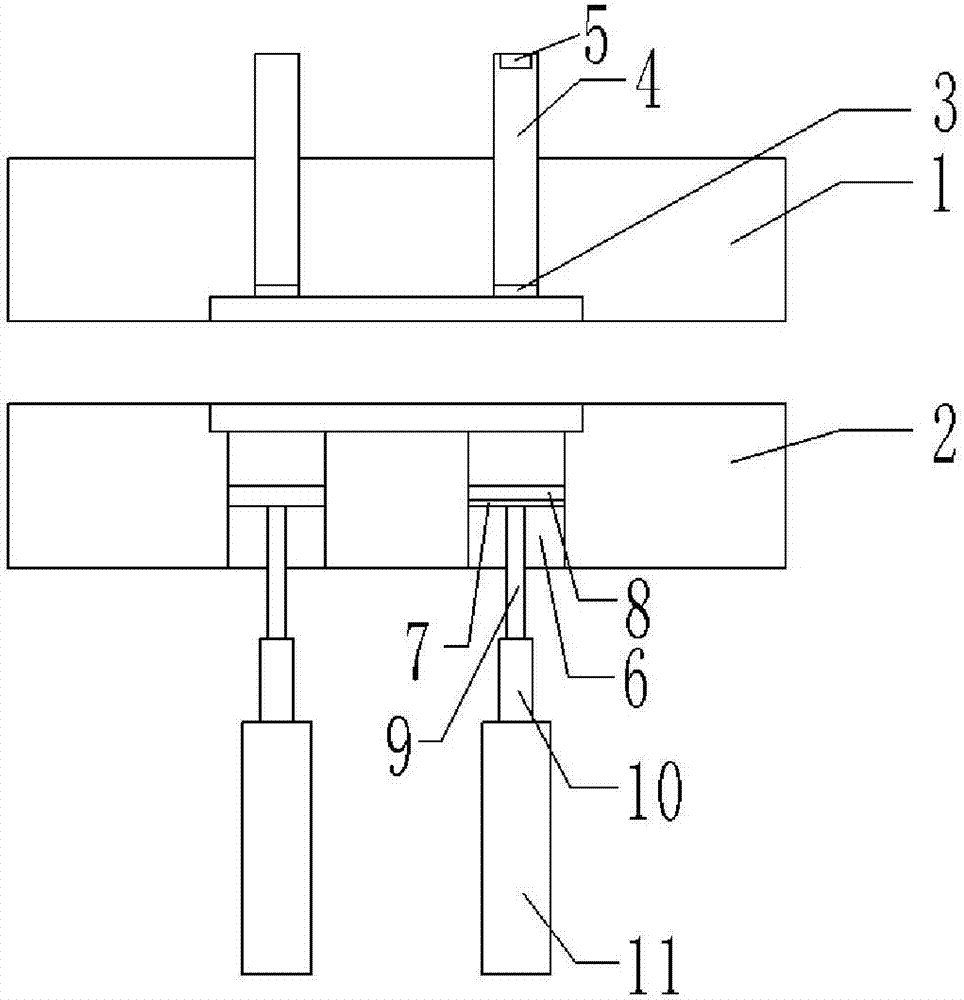

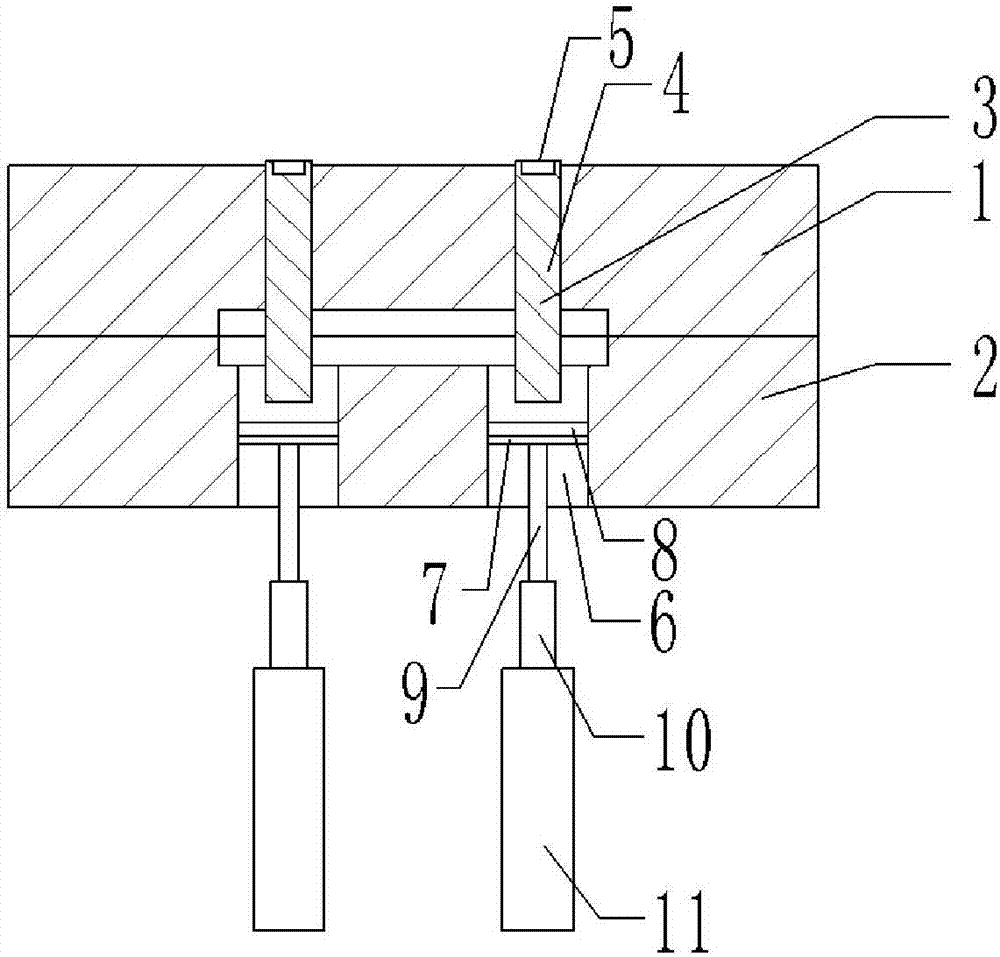

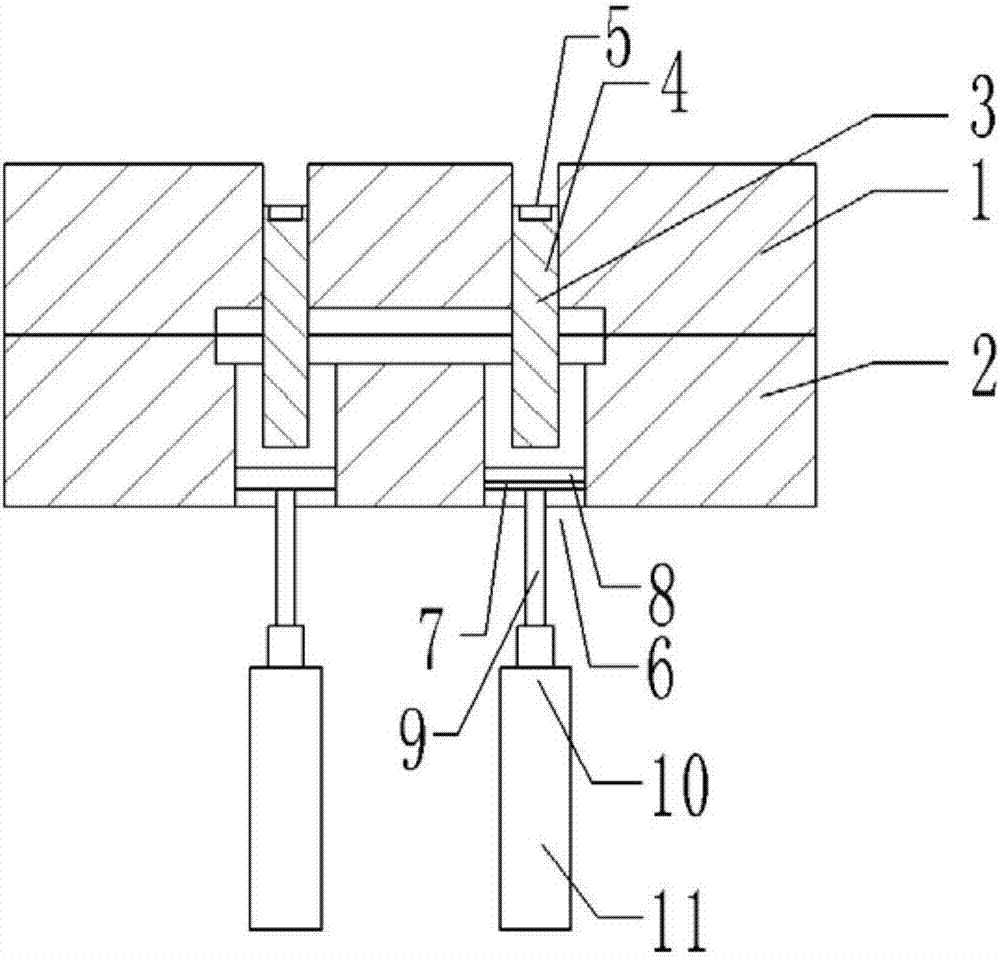

[0028] The reference signs in the drawings of the description include: fixed mold 1, movable mold 2, bottom column hole 3, upper bottom column 4, groove 5, lower bottom hole 6, round plug 7, circular plate 8, fixed rod 9, connection Rod 10, cylinder 11.

[0029] Embodiment is shown in accompanying drawing basically:

[0030] like figure 1Shown, the pallet mold of injection molding various feet among the present invention comprises movable mold 2 and fixed mold 1; Fixed mold 1 is provided with four bottom post holes 3 corresponding to the positions of the feet (only two are shown in the figure ), the bottom column hole 3 is provided with an upper bottom column 4 threadedly connected with the bottom column hole 3, and the upper bottom column 4 is provided with a groove 5 on the end face away from the movable mold 2; the movable mold 2 is provided with the upper bottom col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com