Chamfering tool and chamfering machine

A chamfering and tooling technology, applied in the mechanical field, can solve the problems of low wafer control performance, achieve good versatility, simple repair, and increase the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

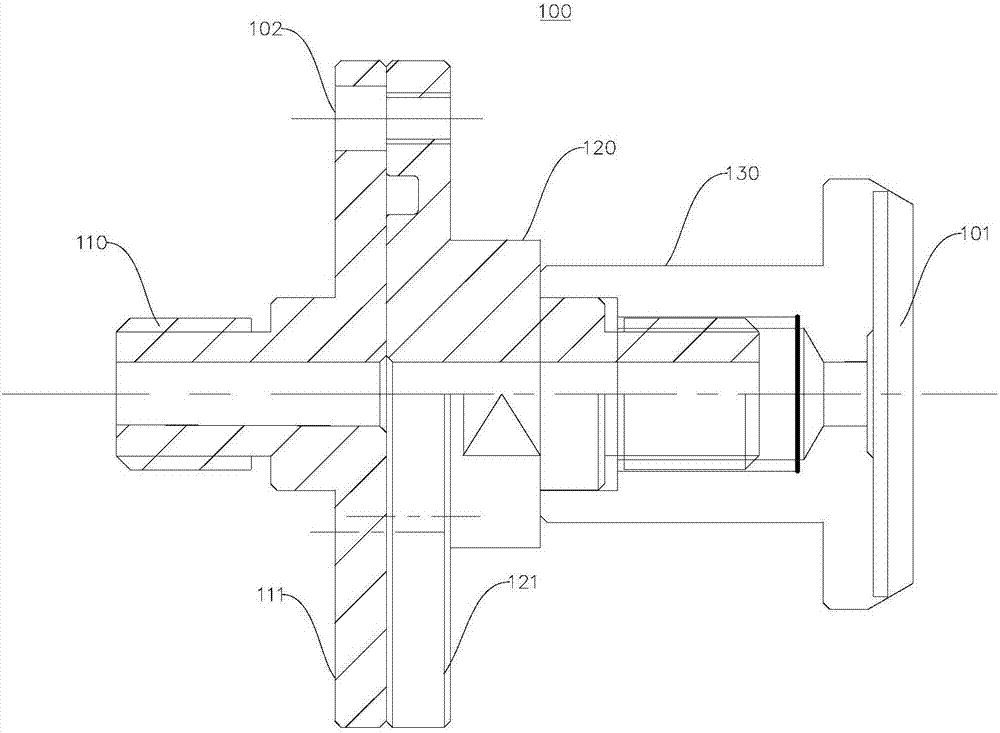

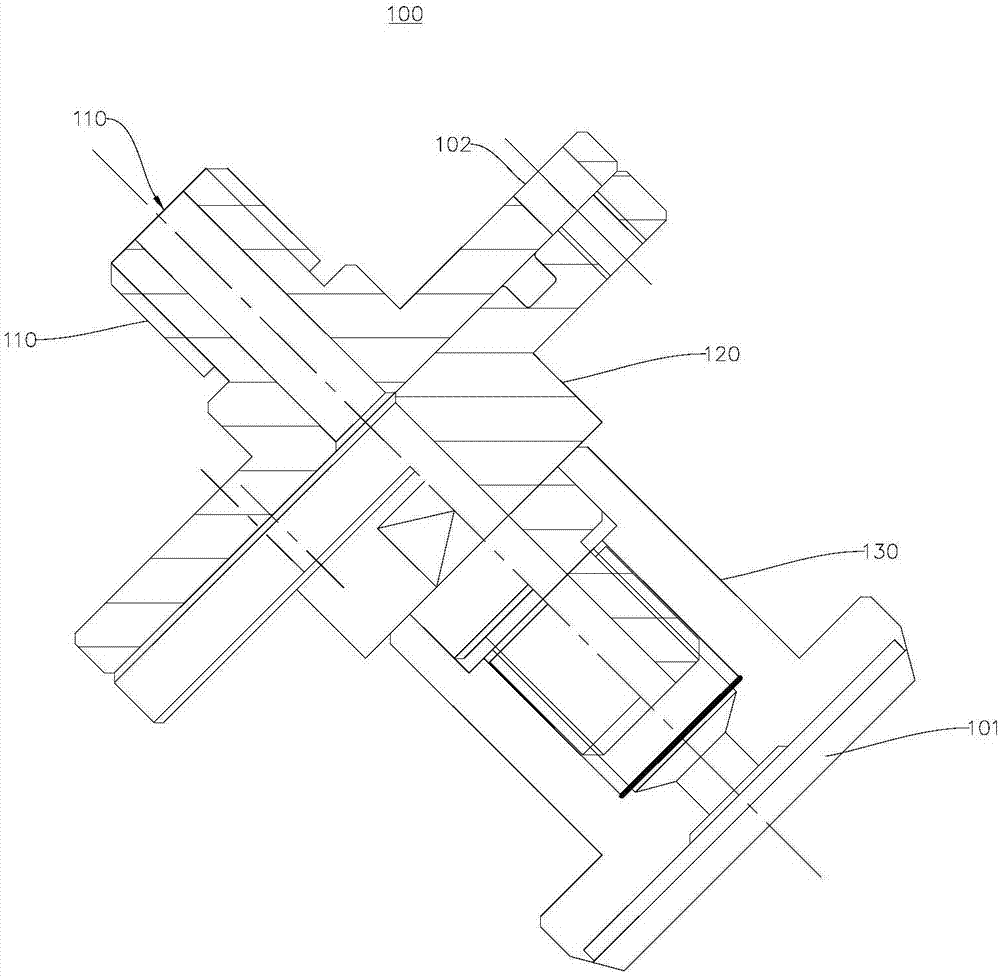

[0038] figure 1 A schematic structural view showing the first state of the chamfering tool 100 provided by the embodiment of the present invention; figure 2 A schematic structural diagram showing the second state of the chamfering tool 100 provided by the embodiment of the present invention; please refer to figure 1 , figure 2 , this embodiment provides a chamfering tool 100, the chamfering tool 100 is mainly used for clamping the wafer 101, and chamfering the wafer 101.

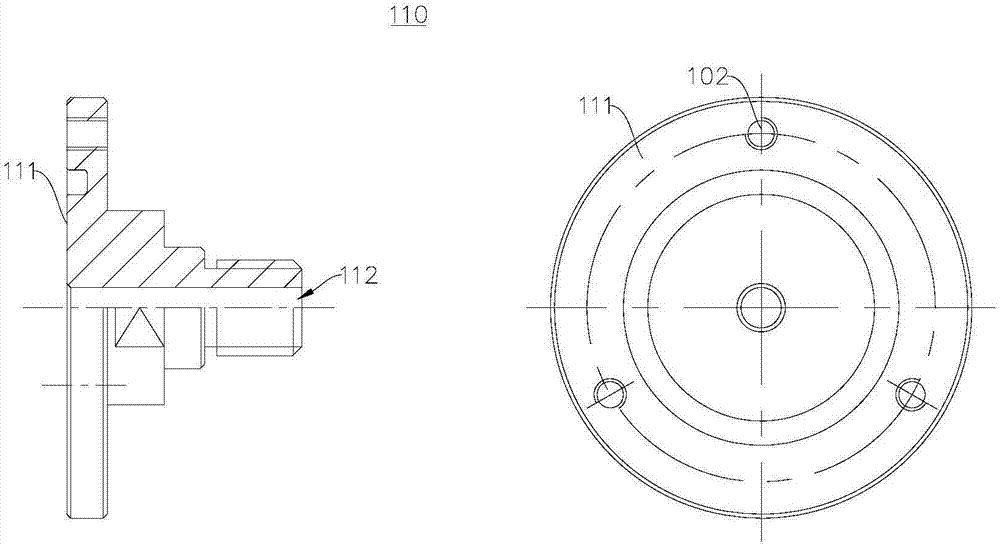

[0039] In detail, in this embodiment, the chamfering tool 100 includes a first joint 110, a second joint 120, and a wafer fixture 130; the first joint 110 is connected to the second joint 120, and the wafer fixture 130 is connected to the second joint 120 . An end of the wafer fixture 130 away from the first joint 110 clamps the wafer 101 .

[0040] Further, the first joint 110 includes a first connecting joint 111; the second joint 120 includes a second connecting joint 121; the second connecting join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com