Thermally-driven digital micro-fluidic chip, manufacturing method and working method thereof

A technology of digital microfluidics and a manufacturing method, applied in the field of microfluidics, can solve the problems of high cost, easily damaged hydrophobic layer, unfavorable repeated use, etc., and achieve the effects of simple structure, low cost, and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

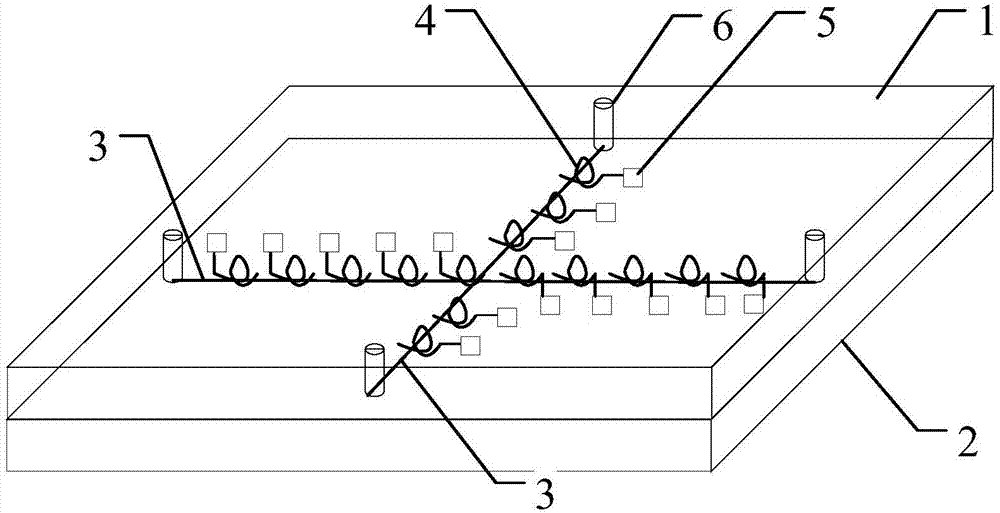

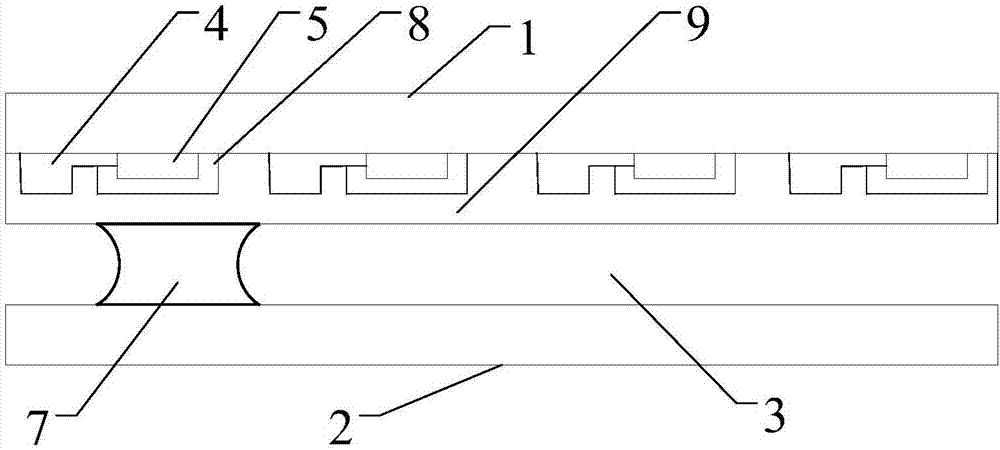

[0043] Exemplary embodiments will now be described more fully with reference to the accompanying drawings. However, the exemplary embodiments can be implemented in a variety of forms, and should not be construed as being limited to the examples set forth herein; on the contrary, the provision of these embodiments makes the present invention more comprehensive and complete, and fully comprehends the concept of the exemplary embodiments. To convey to those skilled in the art. The same reference numerals in the figures represent the same or similar structures, and thus their detailed descriptions will be omitted.

[0044] Although relative terms such as "upper" and "lower" are used in this specification to describe the relative relationship between one component of an icon and another component, these terms are used in this specification only for convenience, for example, according to the drawings. The direction of the example described. It can be understood that if the device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com