Maximum power tracking control method for variable-speed switched reluctance wind generator

A technology of maximum power tracking and wind power generator, which is applied in the direction of synchronous generator control, control of generator through magnetic field change, control of generator, etc. The problem of large switching loss of the tube can be solved, and the effect of simplifying the control complexity, less controllable variables and avoiding fluctuations can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

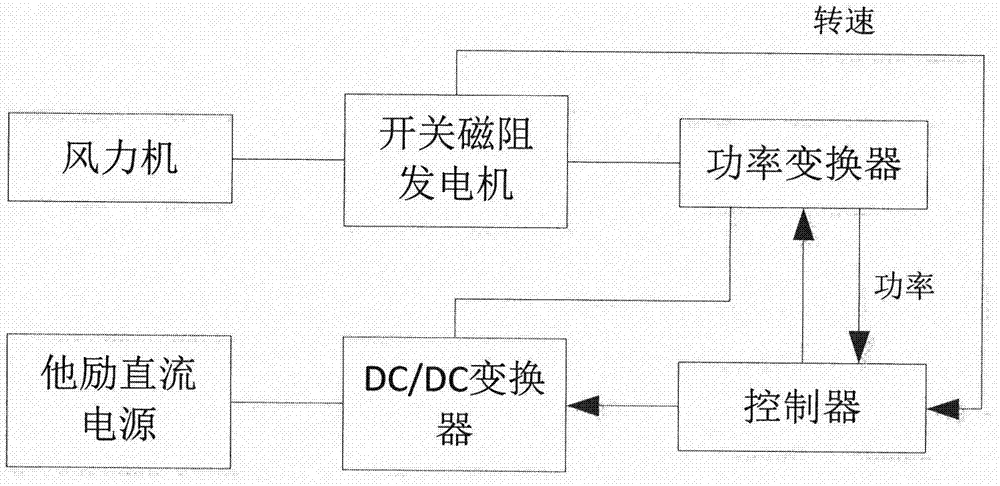

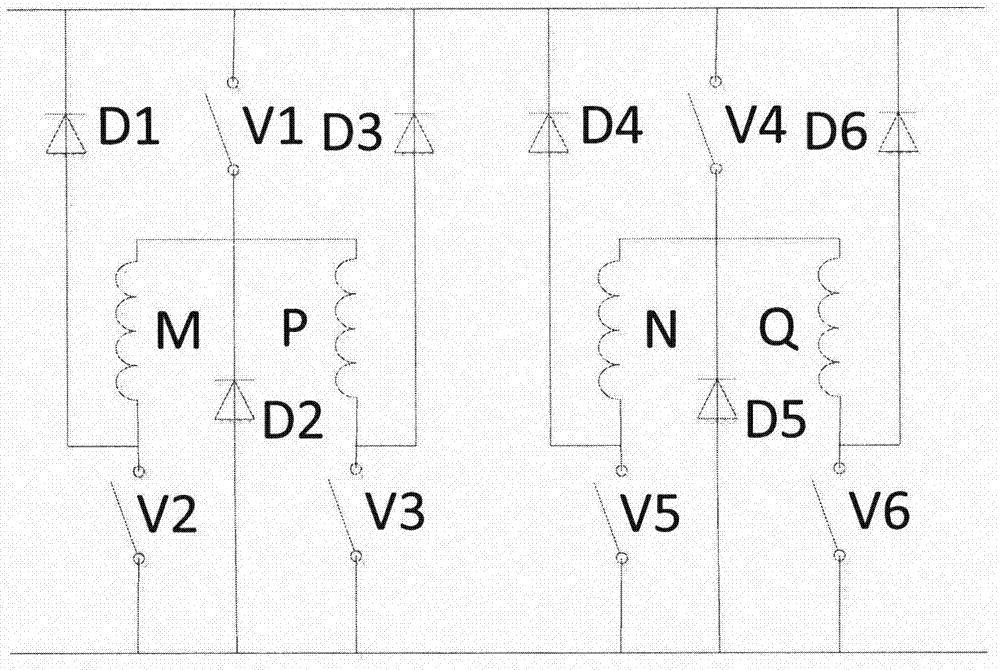

[0021] The switched reluctance generator of this embodiment is a four-phase winding, which are respectively M / N / P / Q four-phase windings according to the order distributed on the stator; the structure of the unit is as follows: figure 1 As shown, the wind turbine drives the switched reluctance generator, and the four-phase winding of the switched reluctance generator is connected to the power converter. The power required for the excitation stage comes from a separately excited DC power source, which can be a battery or other DC power sources such as DC generator set, or converted after receiving the electric energy from the power converter, the output of the separately excited DC power supply cannot be directly used as the excitation power supply, because the excitation voltage of the present invention needs to be finely adjusted, so there is a DC / DC converter in the middle, The controller controls its internal switching tube to realize the adjustment of the output excitation v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com