Logic product yield monitoring structure and design method thereof

A product and logic technology, applied in the field of logic product yield monitoring structure, can solve the problems of effective detection of process health, low product yield, and inability to effectively detect process health, etc. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

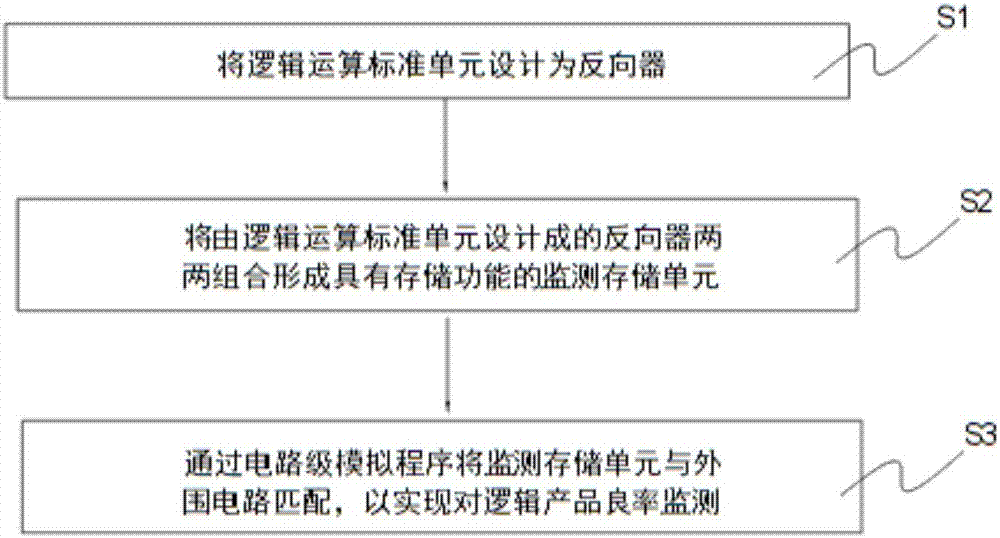

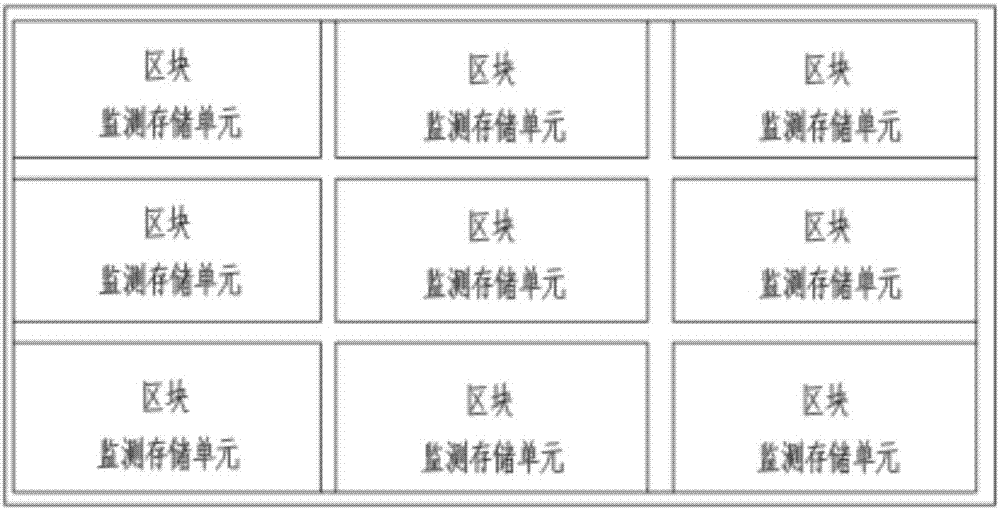

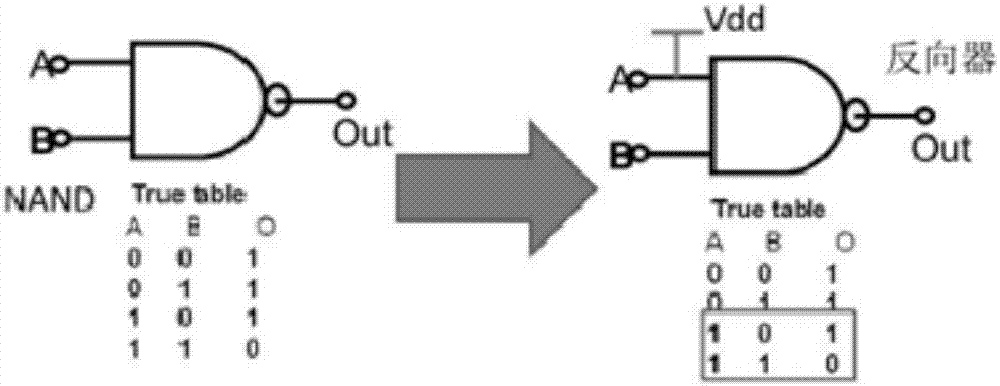

[0030] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0031] With the development of high-level processes, the technical difficulty increases exponentially. What is most needed in process development is the "eye" to monitor the process, that is, various test structures (Test key / Test vehicle) are needed to confirm the abnormal points of the process in the first time, so as to improve and shorten the process development cycle in time.

[0032] At present, due to the limited technical accumulation of domestic preparation manufacturers and the serious shortage of human resources invested in process development, there is an extremely lack of development and application of a complete set of high-level process development and testing structures to achieve high-level process technology development....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com