High-frequency eddy current effect-considered semi-analytical calculation method for winding loss

A technology of eddy current effect and winding loss, applied in calculation, design optimization/simulation, special data processing application, etc., can solve problems such as long calculation time, and achieve the effect of saving calculation time and reducing calculation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

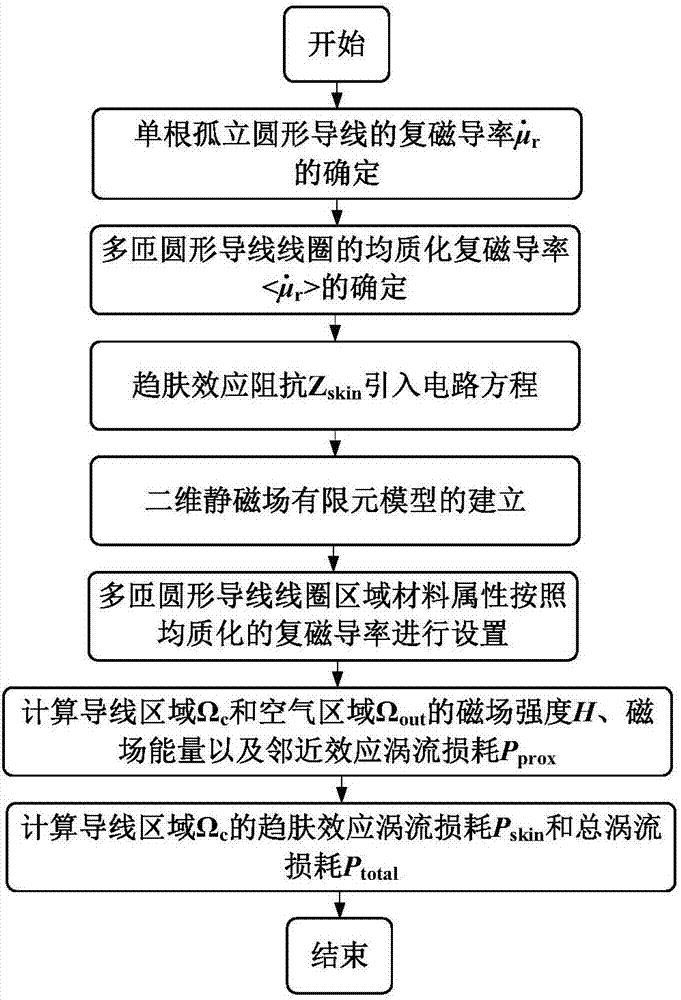

Method used

Image

Examples

Embodiment 1

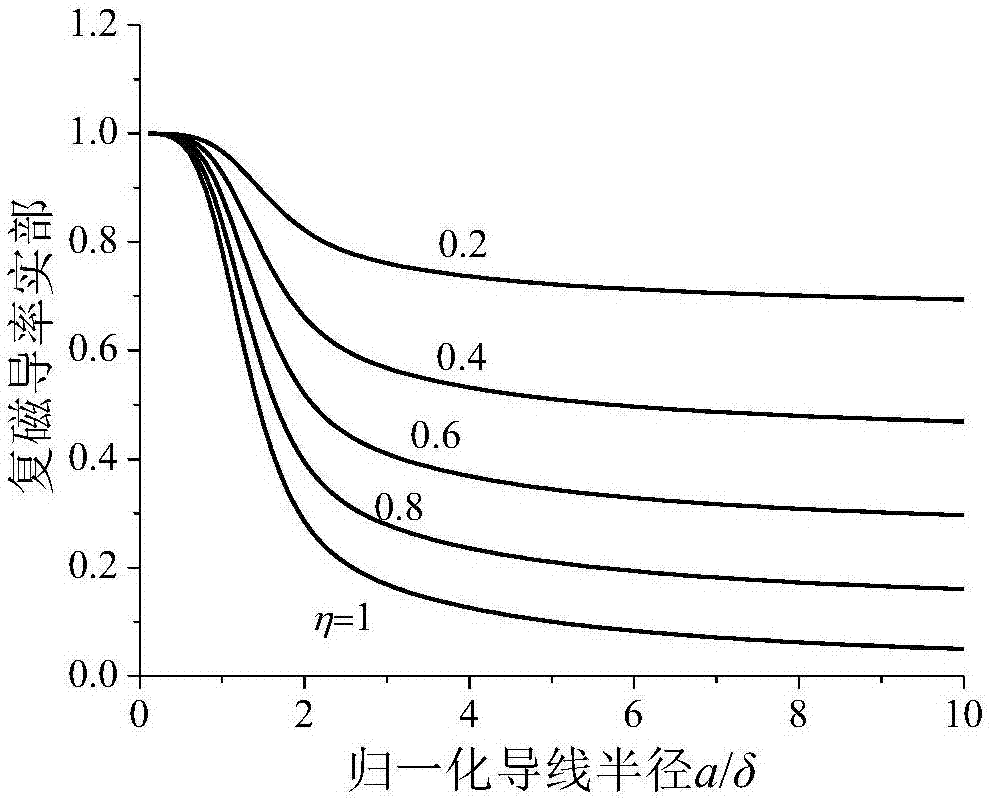

[0108] image 3 and Figure 4 Homogenized complex permeability The real and imaginary parts of the change curve with the normalized thickness a / δ, where μ r =1. At this point, the multi-turn coil can be considered as a magnetic permeability homogeneous material.

[0109] An inductor is made by winding a copper conductor with a diameter of 0.15mm, and the number of turns is 50 turns. Figure 5 This is the structural diagram of a multi-turn wire coil inductor. The enamelled thickness of the wire is 0.03mm, and the wire is wound on the skeleton made of light-cured resin tube. The model is PRH35-ST2 (diameter: 30mm). The filling factor of the wire is η=62.9%. The AC resistance of the above model is calculated by semi-analytical calculation method, the calculated frequency range is 0Hz~0.25MHz, the complex magnetic permeability of the coil part is equal to 0.422-0.212j, and the static magnetic field analysis results at the frequency of 0.1MHz are as follows Figure 6 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com