Synchronous control device for compound servo tension force device and automatic coil winding machine, and method thereof

An automatic winding machine, synchronous control technology, applied in the direction of computer control, coil manufacturing, program control, etc., can solve problems such as abnormal tension conditions that cannot be found immediately, poor quality of finished products, and unsuitable winding products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

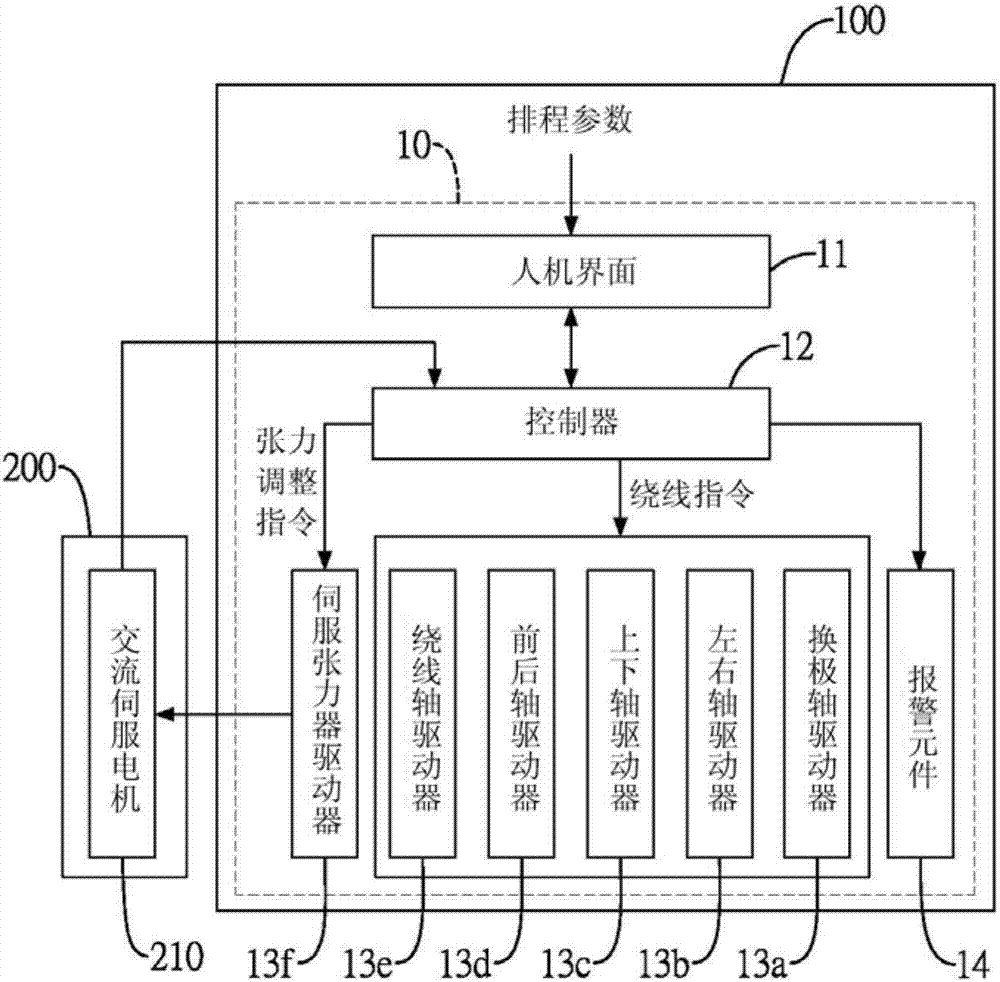

[0042] Please refer to figure 1 As shown, the synchronous control device 10 of the present invention can be installed inside an automatic winding machine 100 to synchronously control the automatic winding machine 100 and a composite servo tensioner 200 . The composite servo tensioner 200 is different from the traditional mechanical tensioner in that it has an AC servo motor 210 inside. By changing the operation of the AC servo motor 210, such as the rotation speed or steering direction, the application of the composite servo tensioner 200 can be changed. For the tension state on the wire, the AC servo motor 210 can provide a feedback tension value to the automatic winding machine 100 . In another embodiment, a tension sensor may also be provided in the composite servo tensioner 200, and the tension sensor detects the instant tension of the wire.

[0043] The synchronous control device 10 includes a man-machine interface 11, a controller 12, and a plurality of drivers 13a-13f....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com