A method for improving the synthesis of polyunsaturated fatty acid oil by Mortierella

A technology of unsaturated fatty acid and Mortierella, which is applied in the field of fermentation engineering, can solve the problems of easy wall hanging of bacterial cells, low yield of polyunsaturated fatty acid oil and low dissolved oxygen concentration, etc., and achieves the effect of good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

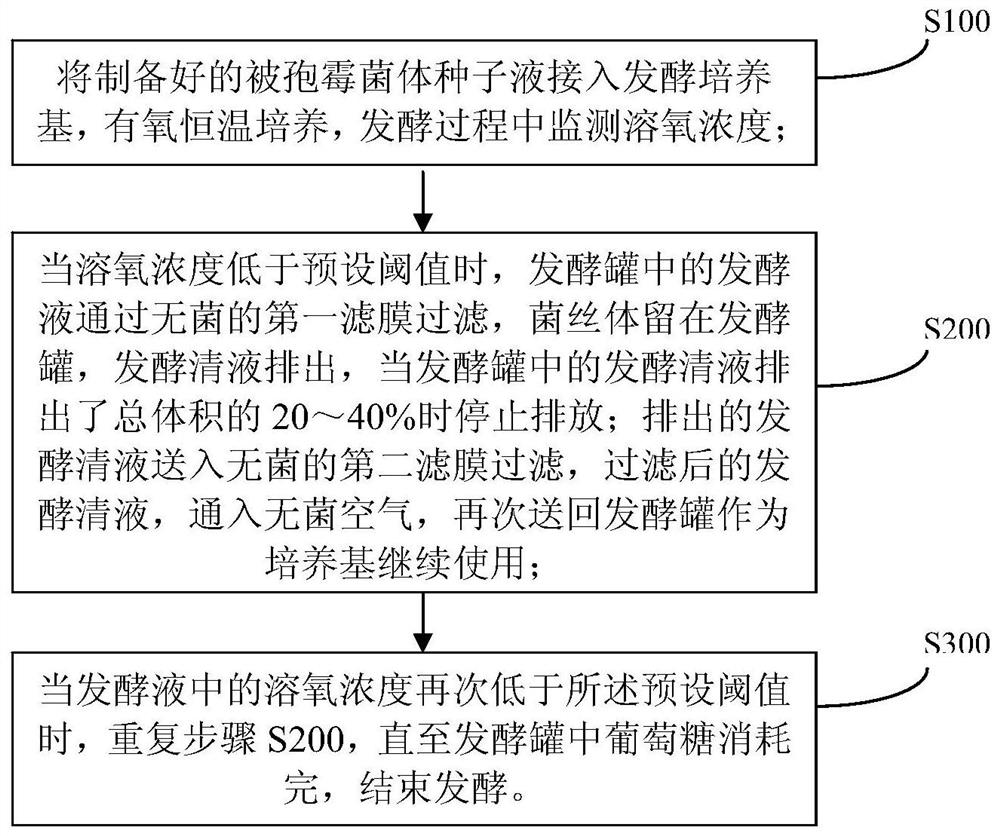

[0026] The method for improving the synthesis of polyunsaturated fatty acid oil by Mortierella of the present embodiment comprises the steps:

[0027] 1) Sterilization

[0028] Add the prepared fermentation medium into the fermenter, and steam sterilize the fermenter, fermentation medium, filter device and connected pipelines;

[0029] 2) Aerobic constant temperature culture

[0030] Put the prepared Mortierella alpina seed liquid into the fermentation medium, 100L fermenter, 200rpm, ventilation rate 1.5vvm, 25°C constant temperature culture, monitor the dissolved oxygen concentration during the fermentation process;

[0031] 3) Reflux of oxygen-enriched fermentation supernatant

[0032] When the dissolved oxygen concentration is lower than the saturation percentage of 10% oxygen, the fermented liquid in the fermenter is filtered through a sterile first filter membrane, the pore size of the first filter membrane is 50-200 μm, and the mycelium is left in the fermenter for fer...

Embodiment 2

[0037] The method for improving the synthesis of polyunsaturated fatty acid oil by Mortierella of the present embodiment comprises the steps:

[0038] 1) Sterilization

[0039] Add the prepared fermentation medium into the fermenter, and steam sterilize the fermenter, fermentation medium, filter device and connected pipelines;

[0040] 2) Aerobic constant temperature culture

[0041] Put the prepared Mortierella deepflavus seed liquid into the fermentation medium, 100L fermenter, 400rpm, ventilation rate 0.8vvm, 30°C constant temperature culture, monitor the dissolved oxygen concentration during the fermentation process;

[0042] 3) Reflux of oxygen-enriched fermentation supernatant

[0043] When the dissolved oxygen concentration is lower than the saturation percentage of 20% oxygen, the fermentation liquid in the fermenter is filtered through a sterile first filter membrane, the pore size of the first filter membrane is 50-200 μm, and the mycelium is left in the fermenter fo...

Embodiment 3

[0049] The method for improving the synthesis of polyunsaturated fatty acid oil by Mortierella of the present embodiment comprises the steps:

[0050] 1) Sterilization

[0051] Add the prepared fermentation medium into the fermenter, and steam sterilize the fermenter, fermentation medium, filter device and connected pipelines;

[0052] 2) Aerobic constant temperature culture

[0053] Put the prepared Mortierella Ramanii seed liquid into the fermentation medium, 100L fermenter, 300rpm, ventilation rate 1.0vvm, 27°C constant temperature culture, monitor the dissolved oxygen concentration during the fermentation process;

[0054] 3) Reflux of oxygen-enriched fermentation supernatant

[0055] When the dissolved oxygen concentration is lower than the saturation percentage of 17% oxygen, the fermentation broth in the fermenter is filtered through a sterile first filter membrane, the first filter membrane has a pore size of 50-200 μm, and the mycelium is left in the fermenter for f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com