Modularized joint for seven-freedom-degree cooperative mechanical arm

A technology of modular joints and mechanical arms, applied in the field of robots, can solve the problems of difficult mass production, difficult assembly, poor dust resistance, etc., and achieve the effects of easy mass production, simplified transmission process, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

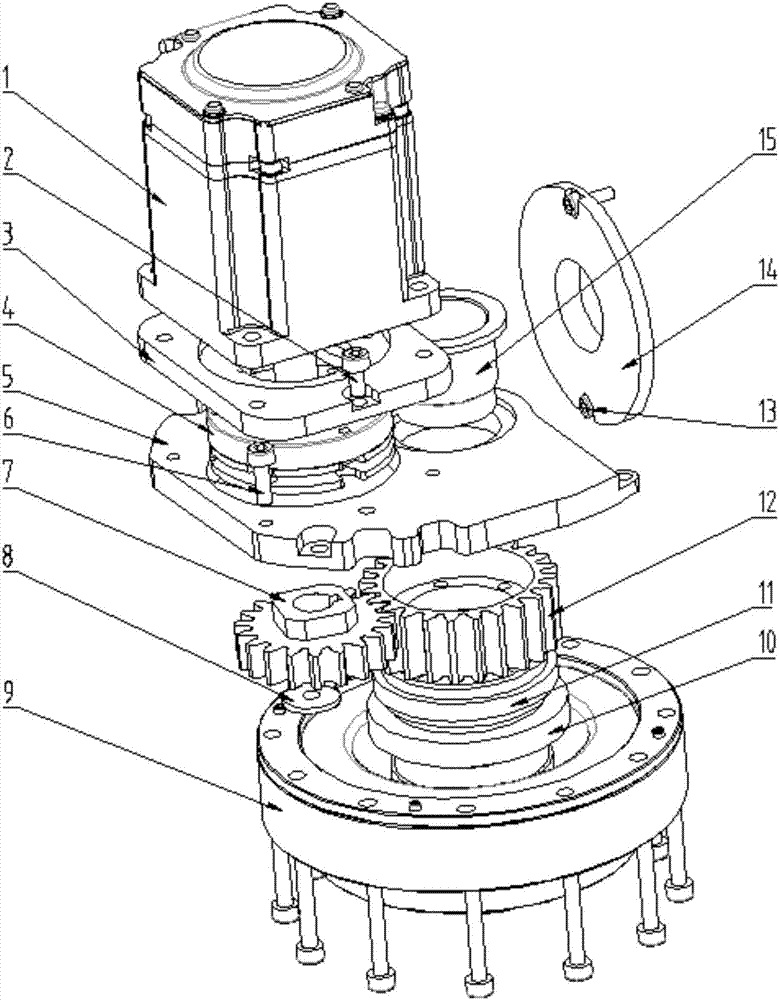

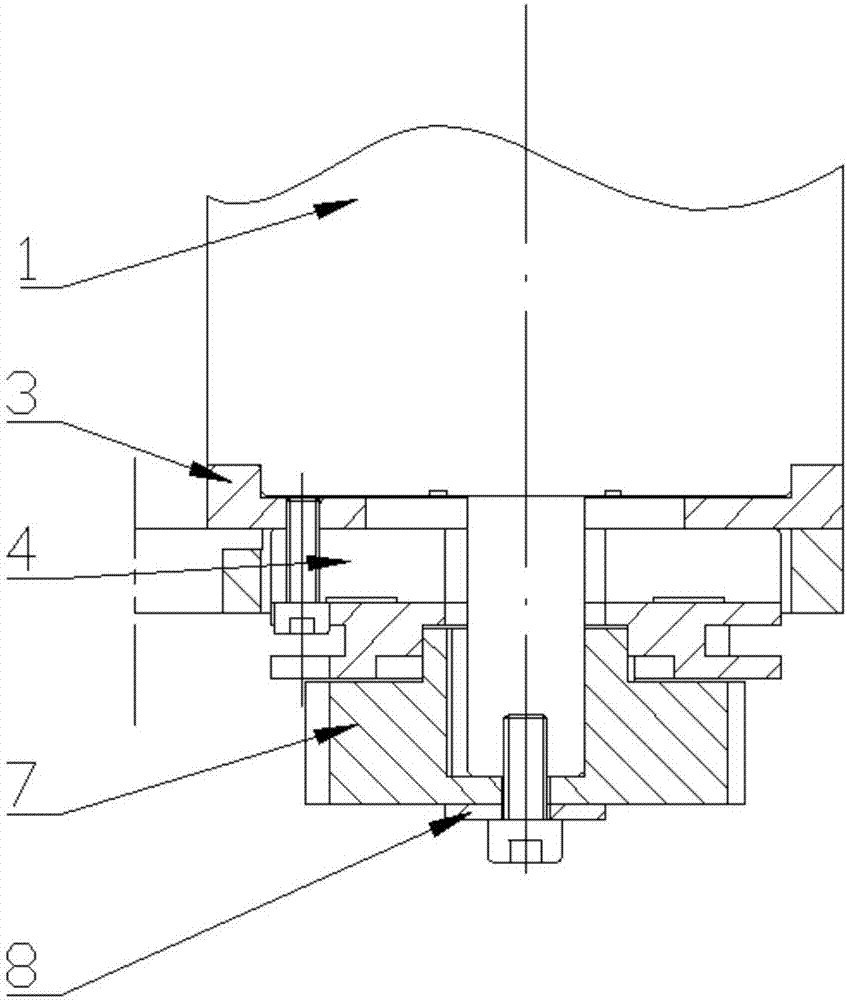

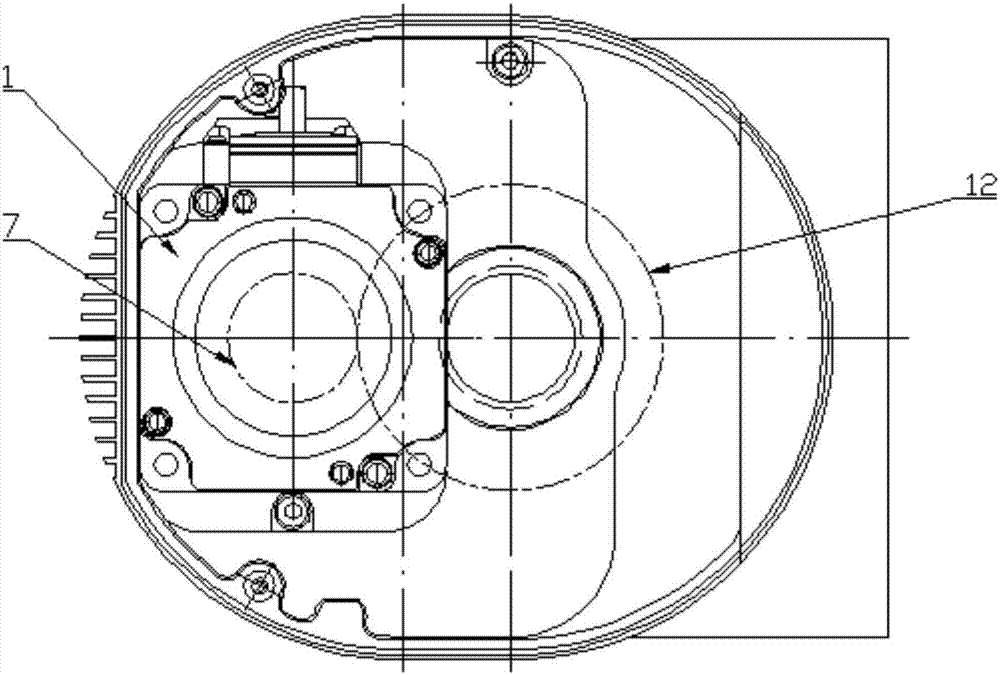

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific installation and working methods.

[0019] As shown in the accompanying drawings, a modular joint for a seven-degree-of-freedom collaborative robotic arm of the present invention includes a housing 17, and an end cover 16 is installed on the top of the housing 17, preferably the housing 17 and the end cover Sealing ring is installed between 16.

[0020] A metal bracket 5 is fixed on the inner upper part of the housing, preferably on the metal bracket, there are a plurality of screw holes connecting the metal bracket and the housing in the vertical direction, and the metal bracket can pass through the screw holes The screw 6 is fixedly connected with the shell. On the top surface of described metal support 5, fix (can be by screw 2) have servo motor fixed plate 3, have mounting hole at the center of described servo motor fixed plate, the bottom of servo mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com