Special-shaped columnar spring testing fastening method

A columnar and special-shaped technology, which is applied in the spring fastening field of special-shaped columnar spring testing, can solve the problems of inconvenient adjustment and small application range of the spring tester, and achieve the effect of simple structure, ingenious design and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

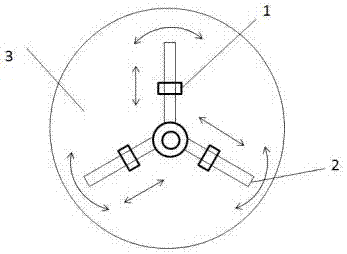

[0010] A spring fastening method for special-shaped columnar spring testing. A special-shaped columnar spring is fixed. There are three radial linear slide rails 2 starting from the center of the base. The slide rails can rotate 360° around the center of the circle. Each slide rail 2 has a There is a slider 1 that can adjust the position along the slide rail arbitrarily. The slider 1 can move arbitrarily along the slide rail 2. Each slider 1 has a regular hexagonal hole vertically penetrating from top to bottom. Each hole are inserted into a regular hexagonal cylinder. First adjust the position of the slider according to the shape of the spring, and when it is initially fixed, insert the cylinder, insert the elliptical columnar spring into the triangle formed by the three cylinders, and then adjust the position of the slider properly to make it tight and suitable .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com