Automatic roller shearing, cutting, edging and filleting integrated device

An automatic and edging technology, applied in other manufacturing equipment/tools, electrical components, printed circuit manufacturing, etc., can solve problems affecting enterprise efficiency, low efficiency, high labor intensity, etc., to solve operational safety problems, save labor, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

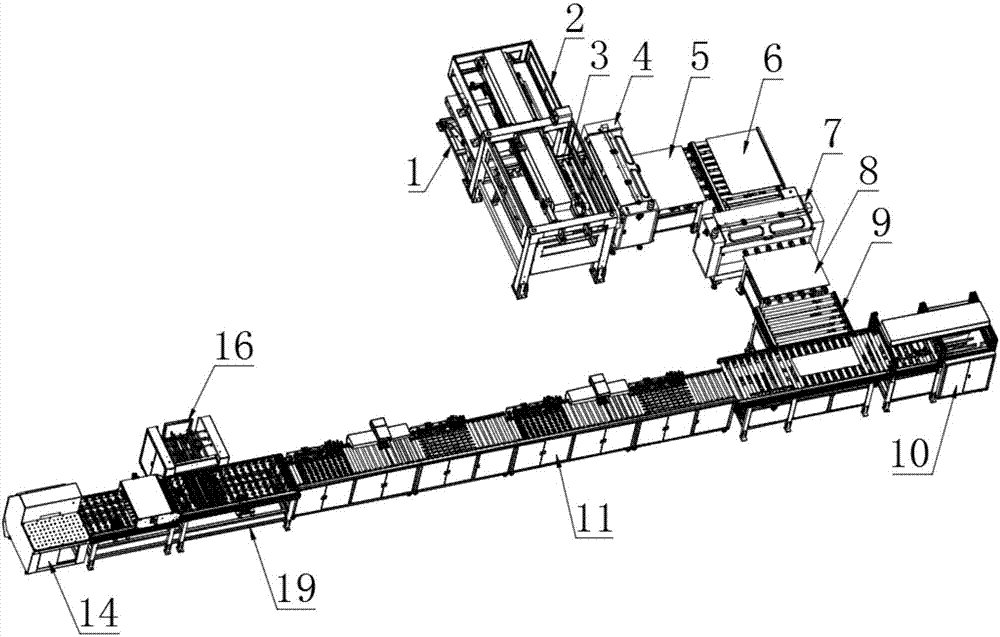

Embodiment 1

[0029] see figure 1, an automatic roller shear cutting material edging and rounding integrated device, including a hydraulic lifting platform 1, a substrate suction lifting transfer machine 2, a side conveyor 3, a right reference rolling shear cutting machine 4, and a first temporary storage conveyor Machine 5, side-by-side corner conveyor 6, left reference rolling shear cutting machine 7, second temporary storage conveyor 8, panel conveyor 9 and edge grinding machine; the hydraulic lifting platform 1 is installed on the substrate for suction lifting Below the feeding end of the machine 2, and the hydraulic lifting platform 1 is equipped with a manipulator corresponding to it. The hydraulic lifting platform 1 lifts the plate transferred by the manipulator to the feeding end of the substrate suction lifting and transferring machine 2. It is used for adsorption and lifting by the substrate suction and transfer machine 2. The hydraulic lifting platform 1 can be controlled by PLC ...

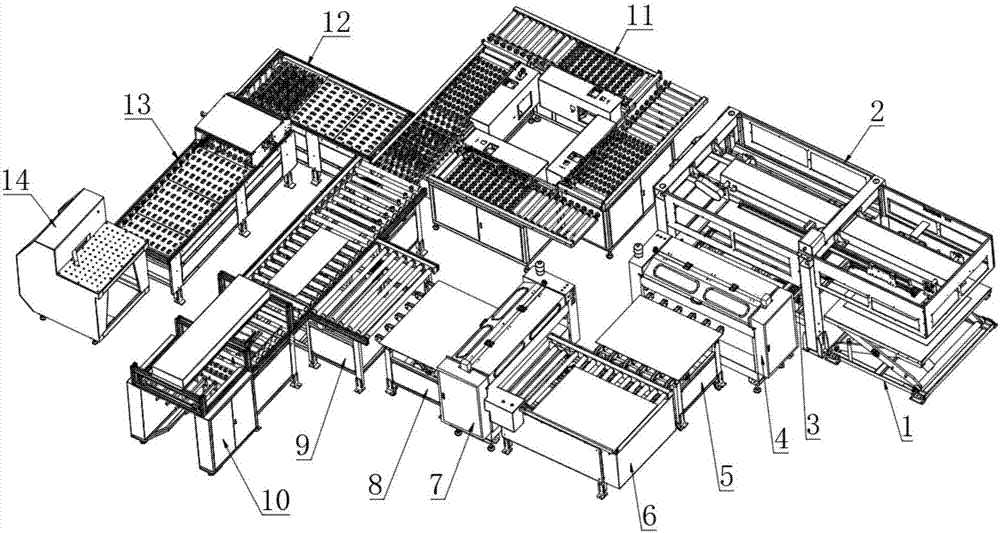

Embodiment 2

[0032] see figure 2 , an automatic roller shear cutting material edging and rounding integrated device, including a hydraulic lifting platform 1, a substrate suction lifting transfer machine 2, a side conveyor 3, a right reference rolling shear cutting machine 4, and a first temporary storage conveyor Machine 5, side-by-side corner conveyor 6, left reference rolling shear cutting machine 7, second temporary storage conveyor 8, panel conveyor 9 and edge grinding machine; the hydraulic lifting platform 1 is installed on the substrate for suction lifting Below the feeding end of the machine 2, and the hydraulic lifting platform 1 is equipped with a manipulator corresponding to it. The hydraulic lifting platform 1 lifts the plate transferred by the manipulator to the feeding end of the substrate suction lifting and transferring machine 2. It is used for adsorption and lifting by the substrate suction and transfer machine 2. The hydraulic lifting platform 1 can be controlled by PL...

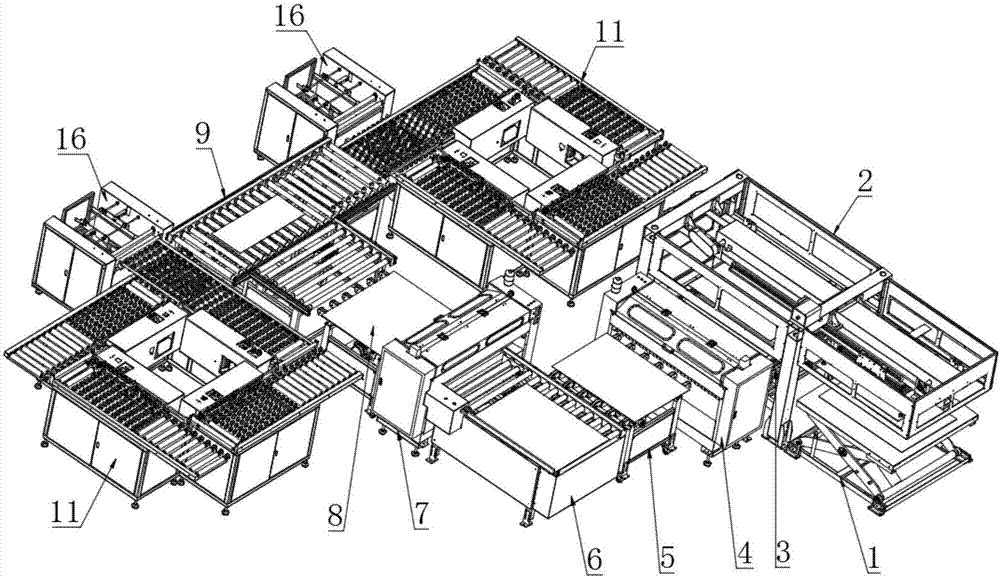

Embodiment 3

[0035] see image 3, an automatic roller shear cutting material edging and rounding integrated device, including a hydraulic lifting platform 1, a substrate suction lifting transfer machine 2, a side conveyor 3, a right reference rolling shear cutting machine 4, and a first temporary storage conveyor Machine 5, side-by-side corner conveyor 6, left reference rolling shear cutting machine 7, second temporary storage conveyor 8, panel conveyor 9 and edge grinding machine; the hydraulic lifting platform 1 is installed on the substrate for suction lifting Below the feeding end of the machine 2, and the hydraulic lifting platform 1 is equipped with a manipulator corresponding to it. The hydraulic lifting platform 1 lifts the plate transferred by the manipulator to the feeding end of the substrate suction lifting and transferring machine 2. It is used for adsorption and lifting by the substrate suction and transfer machine 2. The hydraulic lifting platform 1 can be controlled by PLC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com