Multifunctional emulsification tank

An emulsification tank, multi-functional technology, applied in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve problems such as poor emulsification effect, increased noise, vibration, increased energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

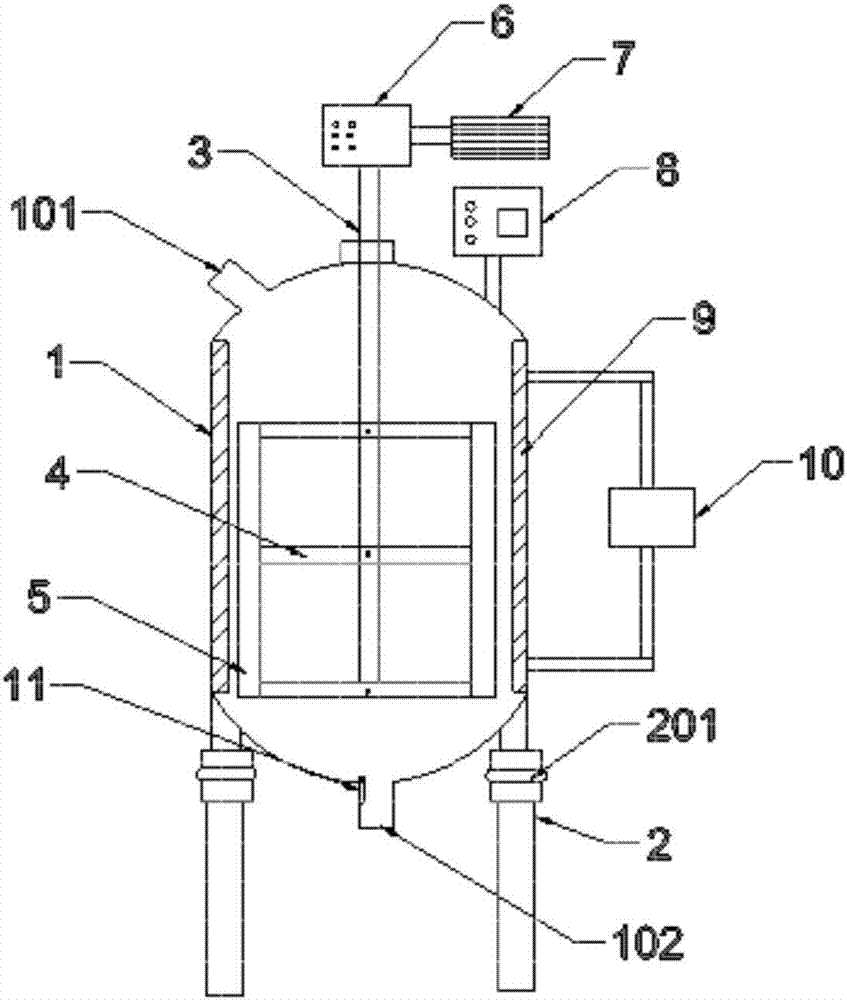

[0015] A multifunctional emulsification tank, comprising a tank body 1, a feed inlet 101 at the top of the tank body 1, and a discharge port 102 at the bottom of the tank body 1; A set of stirring blades 4 is provided, and the two ends of the stirring blades 4 can perform telescopic movement along the direction of the stirring shaft 3, and a scraper 5 is arranged at both ends of the stirring blades 4, and the stirring shaft 3 protrudes from the tank body 1, and one end is sequentially connected with a gearbox 6 and a stirring motor 7, a control panel 8 is arranged on the top of the tank body 1, and the control panel 8 is electrically connected with the stirring blade 4, the gearbox 6 and the stirring motor 7.

[0016] Working principle: Since the stirring blade 4 is retractable, it needs to be stirred at the beginning of emulsification. The gearbox 6 adjusts the stirring speed of the stirring shaft 3, and the stirring blade 4 expands and contracts in the direction of the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com