Eye drop bottling device applied to ophthalmology

A technology for using eyes and drops, applied in liquid bottling, packaging, bottle filling, etc., can solve the problems of waste, easy splashing of eye drops, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

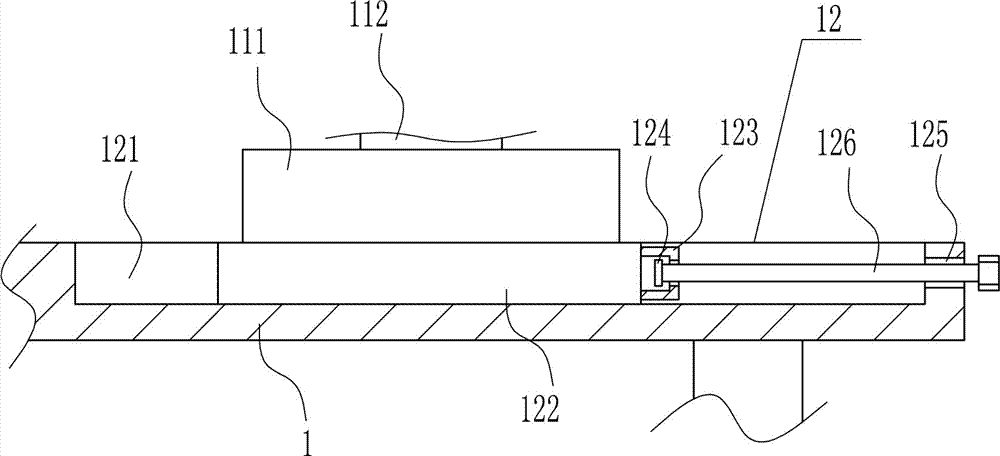

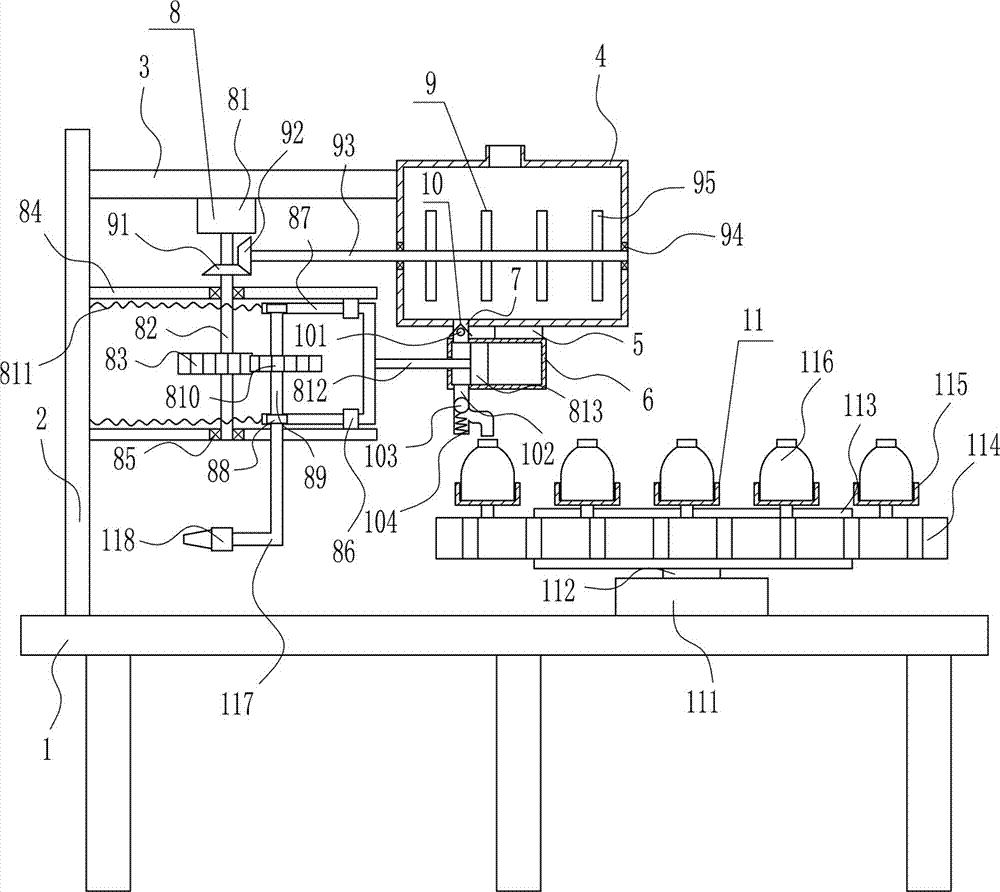

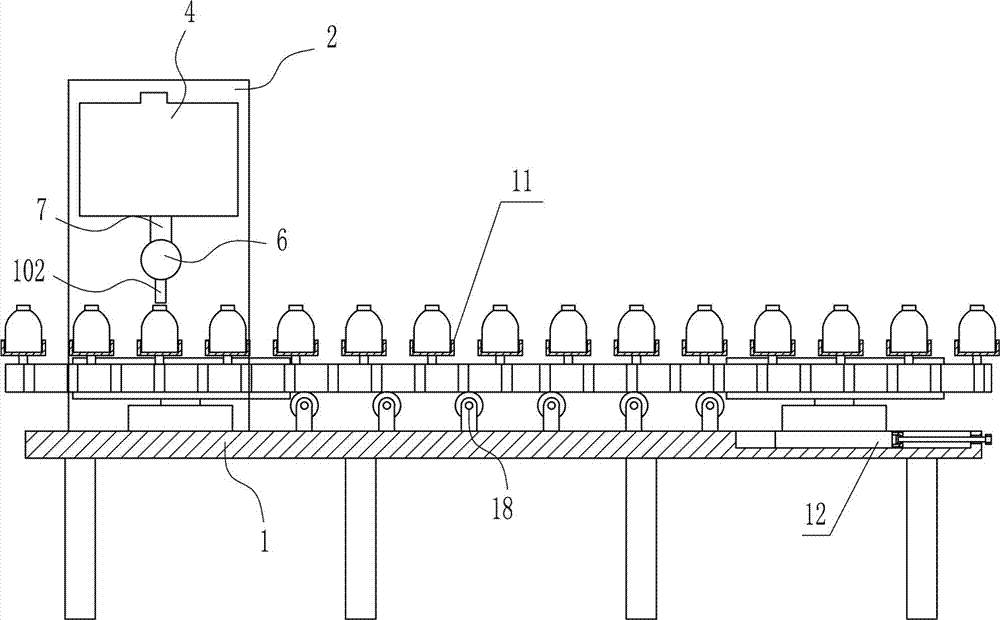

[0037] An ophthalmic eye drop bottling device, such as Figure 1-7 As shown, it includes console 1, support plate 2, cross bar 3, material storage box 4, connecting block 5, compression cylinder 6, discharge pipe 7, pushing device 8 and stirring device 9, and the top left side of console 1 is installed There is a support plate 2, a cross bar 3 is installed on the right side of the support plate 2, a material storage box 4 is installed on the right end of the cross bar 3, and a discharge pipe 7 is connected to the left side of the bottom of the material storage box 4, and the discharge pipe 7 is connected to the storage material The inside of the box 4 is connected. A connection block 5 is installed in the middle of the outer bottom of the storage box 4. A compression cylinder 6 is installed at the bottom of the connection block 5. The left side of the top of the compression cylinder 6 is connected to the tail end of the discharge pipe 7. The compression cylinder 6 is connected ...

Embodiment 2

[0039] An ophthalmic eye drop bottling device, such as Figure 1-7 As shown, it includes console 1, support plate 2, cross bar 3, material storage box 4, connecting block 5, compression cylinder 6, discharge pipe 7, pushing device 8 and stirring device 9, and the top left side of console 1 is installed There is a support plate 2, a cross bar 3 is installed on the right side of the support plate 2, a material storage box 4 is installed on the right end of the cross bar 3, and a discharge pipe 7 is connected to the left side of the bottom of the material storage box 4, and the discharge pipe 7 is connected to the storage material The inside of the box 4 is connected. A connection block 5 is installed in the middle of the outer bottom of the storage box 4. A compression cylinder 6 is installed at the bottom of the connection block 5. The left side of the top of the compression cylinder 6 is connected to the tail end of the discharge pipe 7. The compression cylinder 6 is connected ...

Embodiment 3

[0042] An ophthalmic eye drop bottling device, such as Figure 1-7 As shown, it includes console 1, support plate 2, cross bar 3, material storage box 4, connecting block 5, compression cylinder 6, discharge pipe 7, pushing device 8 and stirring device 9, and the top left side of console 1 is installed There is a support plate 2, a cross bar 3 is installed on the right side of the support plate 2, a material storage box 4 is installed on the right end of the cross bar 3, and a discharge pipe 7 is connected to the left side of the bottom of the material storage box 4, and the discharge pipe 7 is connected to the storage material The inside of the box 4 is connected. A connection block 5 is installed in the middle of the outer bottom of the storage box 4. A compression cylinder 6 is installed at the bottom of the connection block 5. The left side of the top of the compression cylinder 6 is connected to the tail end of the discharge pipe 7. The compression cylinder 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com