Electric connector of TYPEC socket

A technology for electrical connectors and sockets, applied in the direction of connections, parts of connecting devices, protective grounding/shielding devices of connecting parts, etc. Production cost, effect of avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

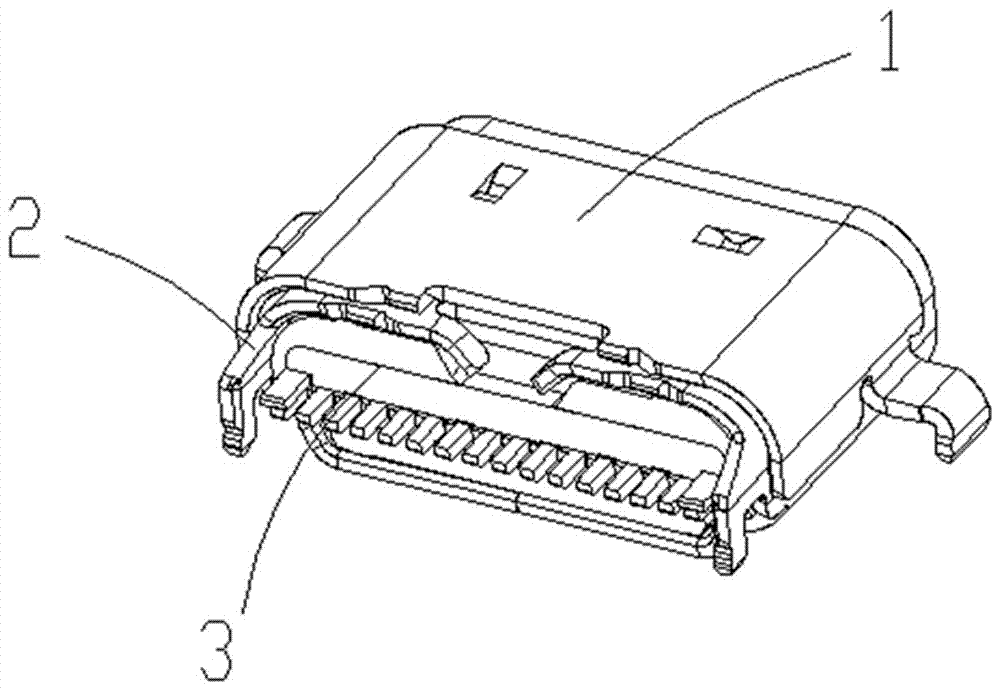

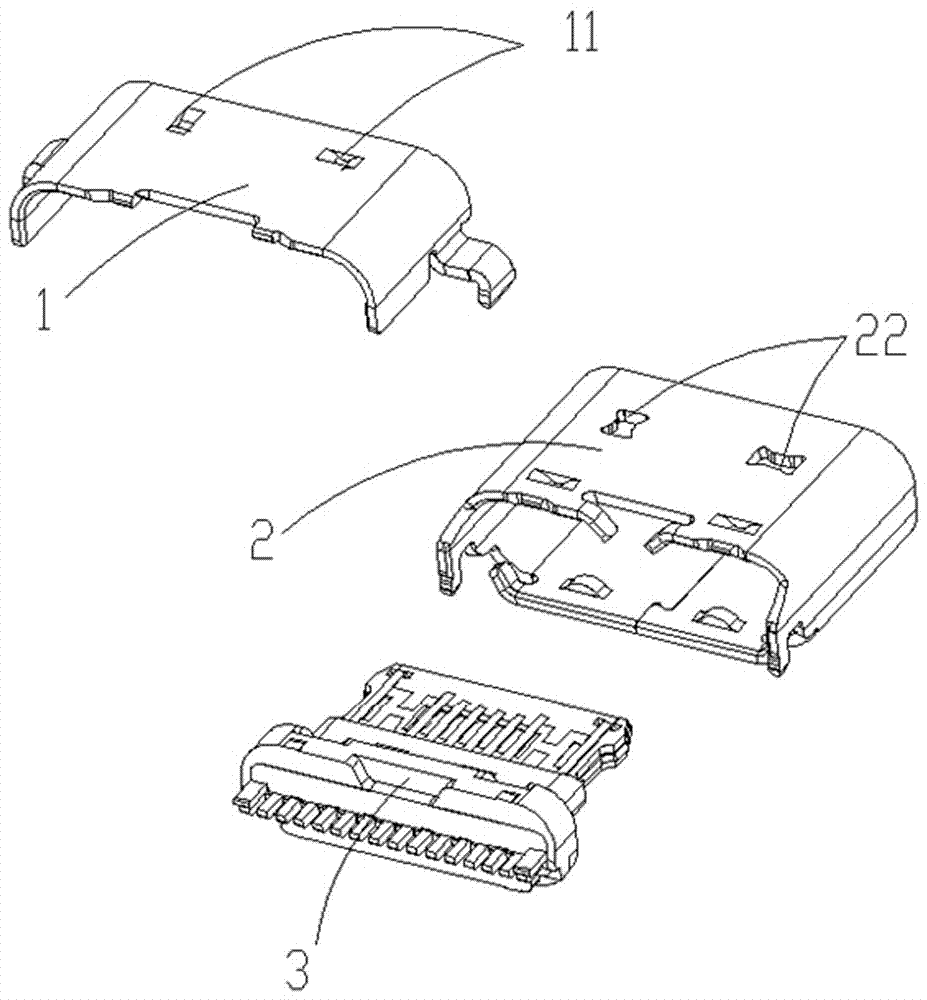

[0020] A TYPEC socket electrical connector is characterized in that it includes an outer shielding shell 1, an inner shielding shell 2, a conductive terminal and a metal grounding sheet module 3; the outer shielding shell 1 is arranged above the inner shielding shell 2; the conductive terminal and the metal grounding sheet The ground sheet module 3 is arranged inside the inner shielding shell 2;

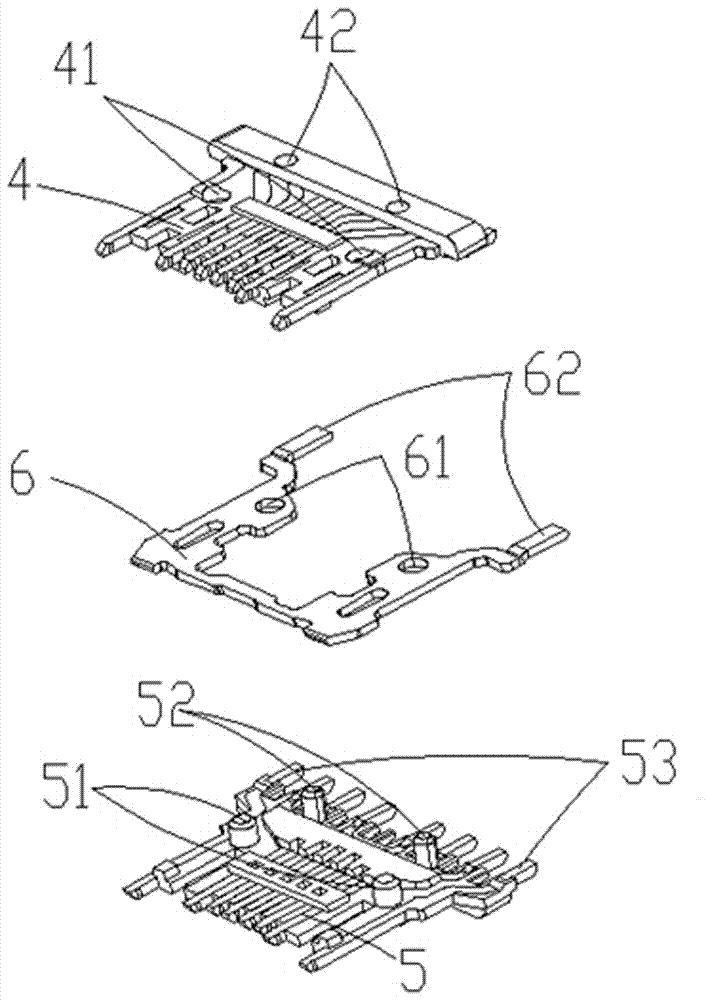

[0021] The conductive terminal and the metal grounding sheet module 3 are, from top to bottom, the upper row of conductive terminal modules 4, the metal grounding sheet 6, and the lower row of conductive terminal modules 5;

[0022] The terminals on both sides of the lower row of conductive terminal modules 5 are grounding terminals 53 , and the metal grounding sheet 6 is in surface contact with the grounding terminals 53 of the lower row of conductive terminal modules 5 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com