Device and method for testing concrete self-constriction under condition of temperature changing

A concrete and self-shrinking technology, applied in measuring devices, electromagnetic measuring devices, and optical devices, etc., can solve the problems of increased air pressure, internal pressure changes, and poor test repeatability of bellows, eliminating test errors and internal The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

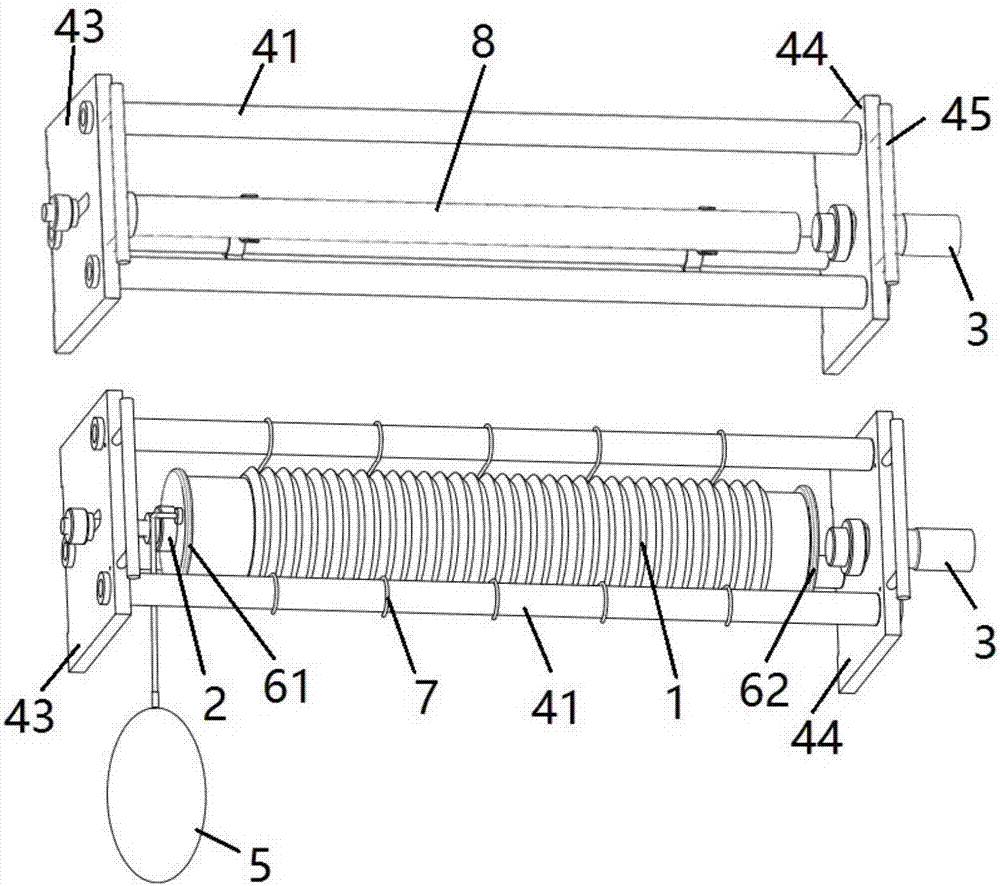

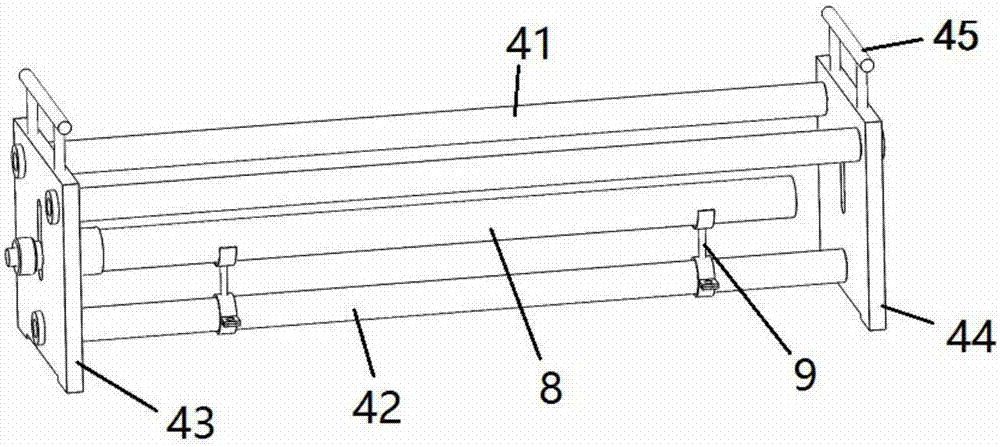

[0083] Simulate the self-shrinkage deformation of a certain C50 concrete under variable temperature conditions, which is used for the simulation calculation of the structural concrete stress field. The temperature change process is set according to the test results in the actual engineering structure. From the beginning, it enters the heating stage, reaching the temperature peak of 79.6°C in the 34th hour, and the concrete temperature drops to 32.0°C in the 352nd hour. The bellows mold used in the test has an inner diameter of 58.5 mm and an outer diameter of 80 mm, and three concrete specimens are used as test objects.

[0084] According to the technical method of the specific embodiment, use 12 hangers to cooperate with the bracket hanger rods, put the concrete into the bellows mold, and use it in a free state with a diameter of 80cm 3 The soft silicone airbag in the inner space is used as a pressure-relief airbag, so that the inside of the bellows mold is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com