Header mechanism of full-automatic labeling machine

A labeling machine, fully automatic technology, applied in the direction of labeling machines, labels, packaging, etc., can solve the problems of frequent occurrence, large resistance, and broken labeling tape, so as to achieve simple travel path, reduce broken tape, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, rather than all the embodiments.

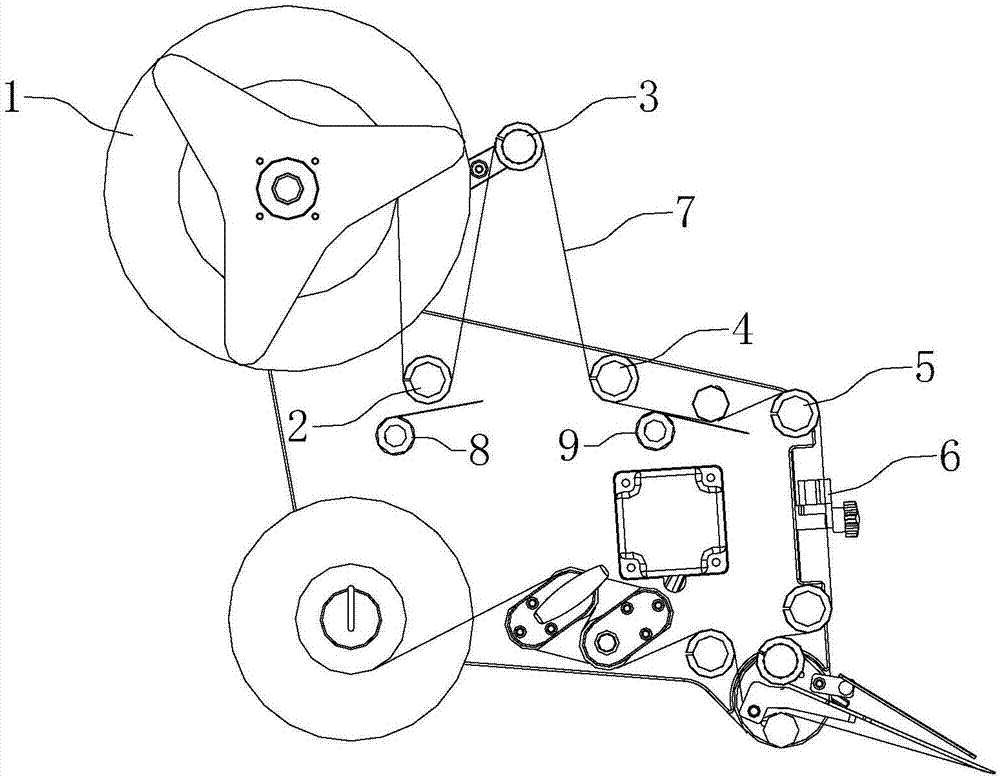

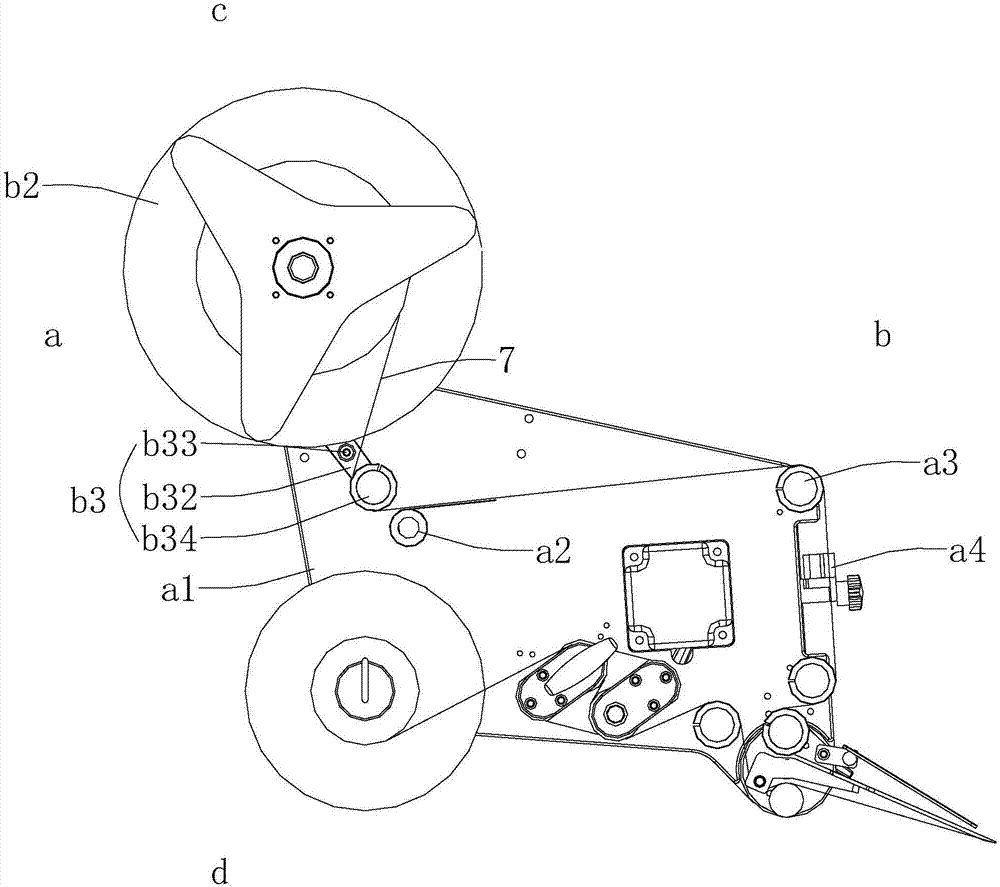

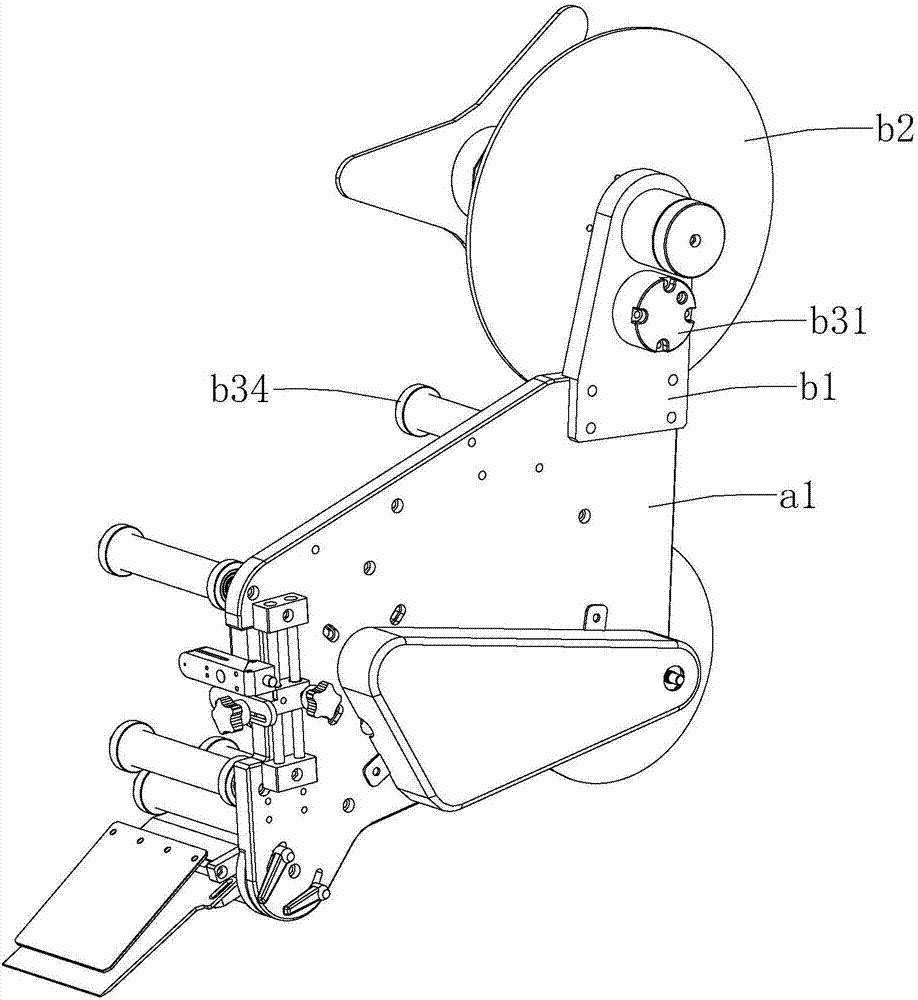

[0052] Reference figure 2 with image 3 In one embodiment, the header mechanism of the fully automatic labeling machine includes a header board a1 and an unwinding rack support board b1, and the unwinding rack support board b1 is arranged above the left side of the header board a1. In this embodiment, figure 2 Side a is the left side in figure 2 Side b in the middle is the right side, with figure 2 The c side in is the upper side, with figure 2 The d side in the middle is downward.

[0053] In this embodiment, the header mechanism of the fully automatic labeling machine also includes a circular tray b2 and a brake mechanism b3. The circular material tray b2 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com