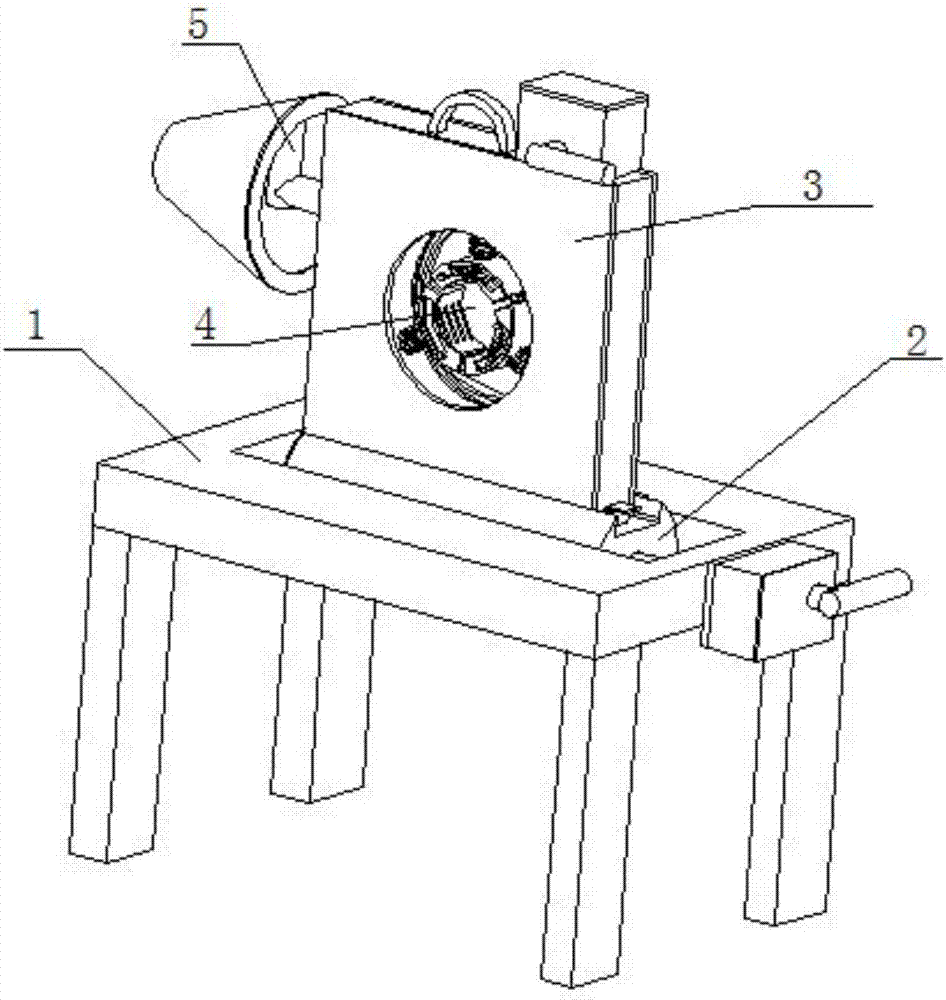

Portable splittable fixture for rotational welding of pipes

A rotary welding and portable technology, which is applied in welding equipment, auxiliary welding equipment, workpiece clamping device, etc., can solve the problems of inability to realize portable use, inability to adjust the angle of the device, and the device is too large, so as to achieve comfortable operation and low weight. Light, clamping way unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

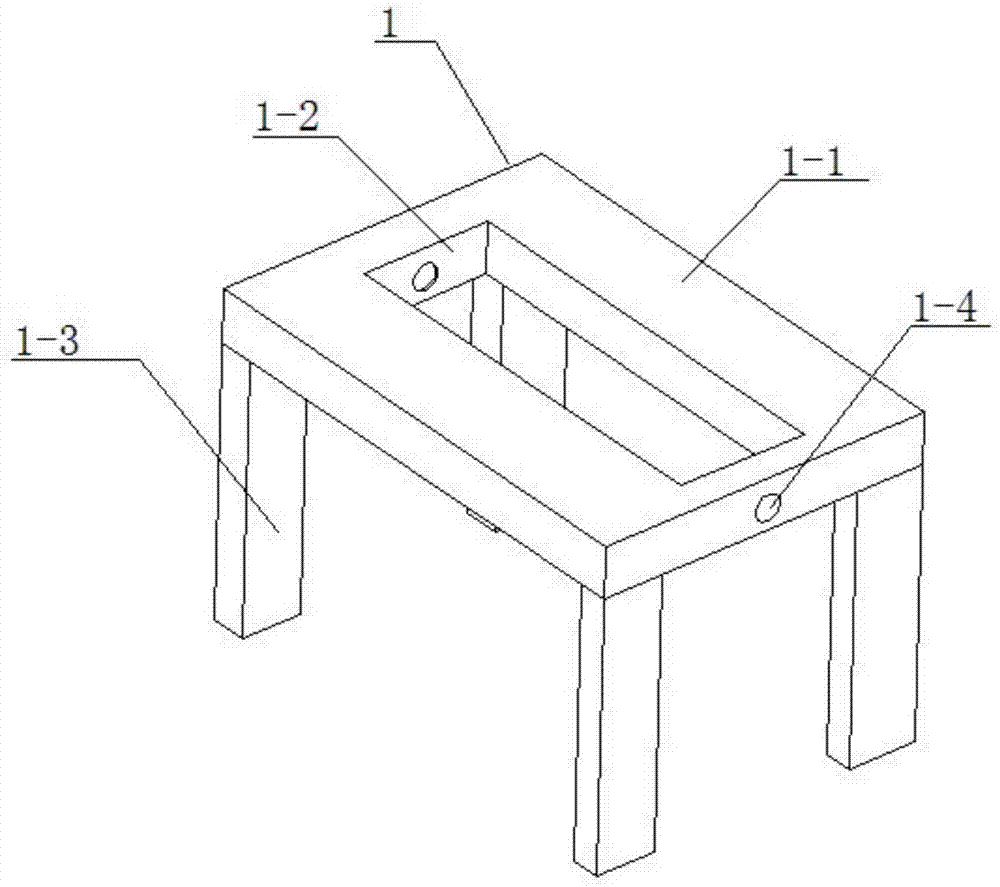

[0029] Such as Figure 1 to Figure 9 As shown, a portable and detachable fixture for rotary welding pipe fittings, the fixed bottom table 1 includes a table board 1-1, a central rectangular groove 1-2, table legs 1-3 and a shaft rotating round hole 1-4, The central rectangular groove 1-2 runs through the center of the table board 1-1 up and down, and there are four table legs 1-3, and the four table legs 1-3 are respectively fixedly connected to the four bottom corners of the lower ends of the table legs 1-3, The shaft rotation circular hole 1-4 is arranged on the right end of the table board 1-1, and the shaft rotation circular hole 1-4 communicates with the central rectangular groove 1-2. The adjustment of the angle of rotation of the fixture structure 4 is realized by the sliding of the fixture structure 4 on the fixture fixing frame 3, and the adjustment of the vertical angle of the fixture structure 4 is realized by the sliding connection of the fixture fixing frame 3 on ...

specific Embodiment approach 2

[0030] Such as Figure 1 to Figure 9 As shown, this embodiment further explains Embodiment 1. The fixed bottom table 1 includes a table plate 1-1, a central rectangular groove 1-2, table legs 1-3 and a shaft rotation hole 1-4, and the central rectangular The groove 1-2 runs through the center of the table board 1-1 up and down, and there are four table legs 1-3, and the four table legs 1-3 are respectively fixedly connected to the four bottom corners of the lower ends of the table legs 1-3. The rotating circular hole 1-4 is arranged on the right end of the table board 1-1, and the axis rotating circular hole 1-4 communicates with the central rectangular groove 1-2.

specific Embodiment approach 3

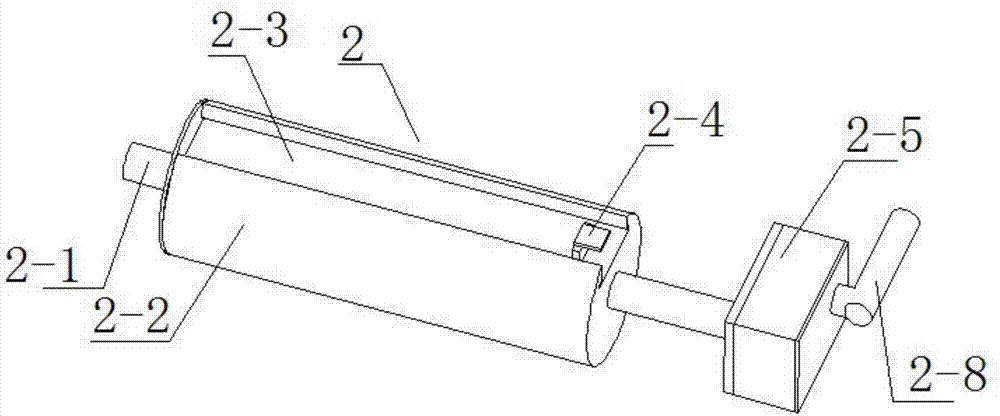

[0031] Such as Figure 1 to Figure 9As shown, this embodiment further explains Embodiment 2. The tea transfer structure 2 includes a rotating shaft 2-1, a rotating round block 2-2, a sliding rectangular slot 2-3, a rectangular inserting block 2-4, and a rotating adjustment Rectangular frame 2-5, driven circular gear 2-6, driving circular gear 2-7 and hand rocker 2-8, rotating shaft 2-1 is rotationally connected to the inner wall of central rectangular groove 1-2, rotating shaft 2-1 is clearance fit The shaft rotates the round hole 1-4, the rotating round block 2-2 is fixedly connected on the rotating shaft 2-1, the sliding rectangular slot 2-3 is arranged on the rotating round block 2-2, and the front and rear ends of the sliding rectangular slot 2-3 are respectively A chute is provided, a rectangular slot is provided on the sliding rectangular slot 2-3, the gap between the rectangular insert 2-4 matches the rectangular slot, and the left end of the rotating and adjusting rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com