Novel photocatalytic material and dual-photocatalytic electrode self-biasing pollution control system

A photocatalytic material and pollution control technology, which can be used in catalyst activation/preparation, water pollutants, light water/sewage treatment, etc. Separation from holes, efficient power generation, and the effect of expanding the Fermi level difference to drive electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

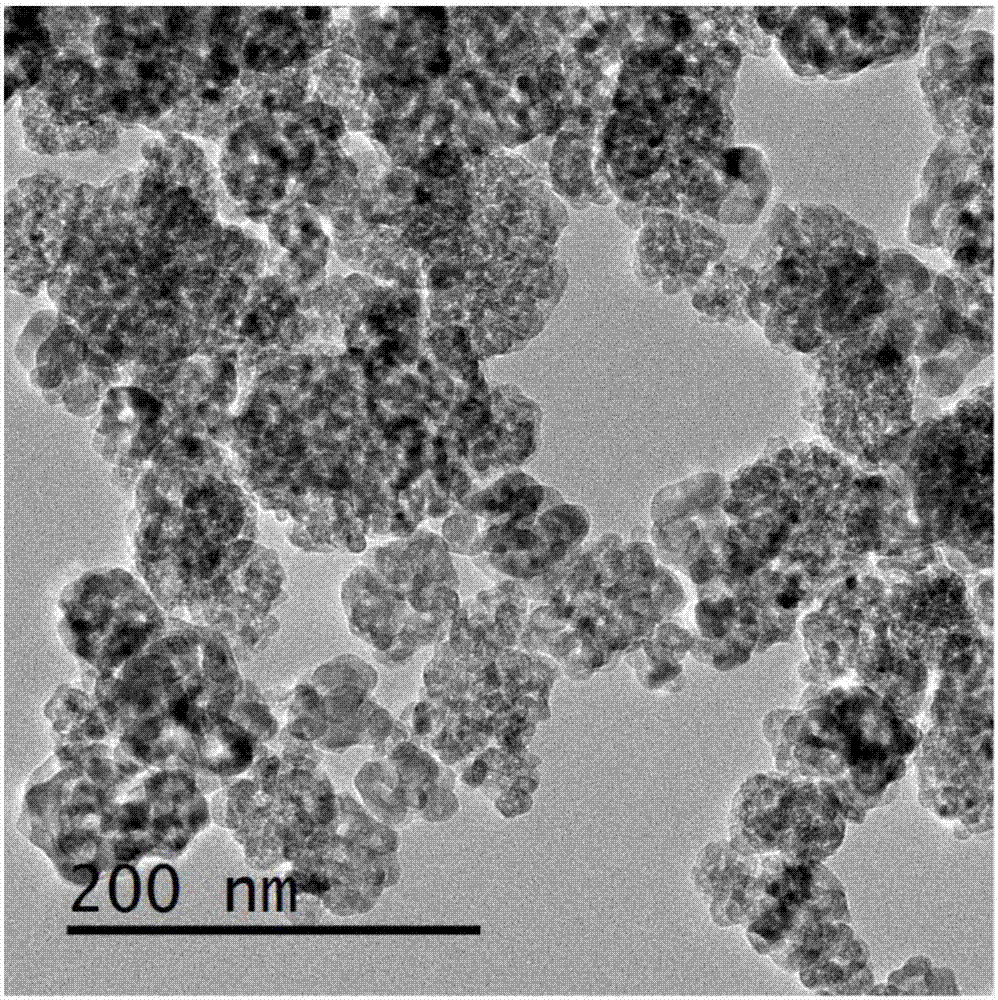

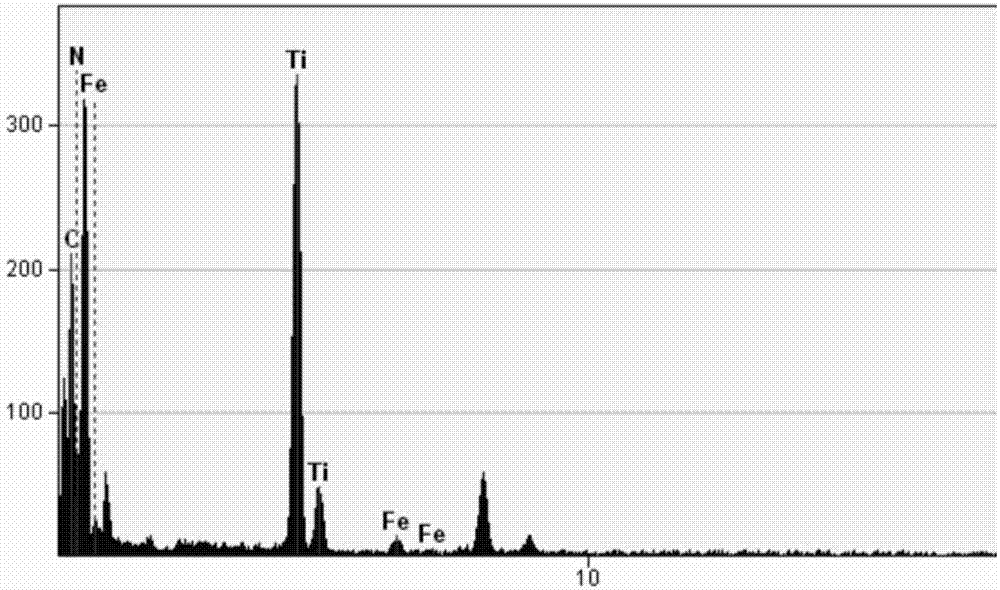

[0023] g-C 3 N 4 -Fe 0 -TiO 2 Photocatalytic powder preparation:

[0024] (1) Fe 0 / TiO 2 Preparation: according to Fe 0 with TiO 2 The mass ratio of 0.5% to TiO 2 Add FeSO to the powder 4 ·7H 2 Add O to 50ml of deionized water, ultrasonically disperse for 30min, then pass nitrogen gas for 30min, then add 0.0136g of NaBH 4 Restore under nitrogen atmosphere for 30 minutes, centrifuge and wash several times, and dry at 60°C for later use.

[0025] (2)g-C 3 N 4 / Fe 0 / TiO 2 Preparation: melamine was calcined at 550°C for 4 hours to obtain g-C 3 N 4 Powder, take 1.00g g-C 3 N 4 Add the powder to HCl (18.5wt%) and ultrasonically disperse it fully for 4 hours, add 500ml of deionized water to dilute, centrifuge and wash several times until neutral, then dry at 105°C to obtain g-C 3 N 4 Nanosheets. Weigh the above g-C 3 N 4 The nanosheet powder was dissolved in deionized water, and the concentration was controlled at 1 mg / mL for 6 hours to obtain a uniform g-C ...

Embodiment 2

[0027] With the g-C prepared in embodiment 1 3 N 4 -Fe 0 -TiO 2 The photocatalytic powder and silica sol were mixed and ultrasonically dispersed at a ratio of 1 mg:1 μL to form a uniform suspension, which was evenly coated on the surface of the pretreated stainless steel mesh and then dried naturally.

[0028] Self-bias system WO 3 The preparation method of the photocatalytic cathode is as follows: configure 50ml of 0.34mol / L sodium tungstate aqueous solution, add about 2ml of 3mol / L hydrochloric acid solution and continue to stir until no precipitation occurs, and leave it for 24h to form a gel. Add 15ml 0.15mol / L CTAB to the above gel, ultrasonically disperse for 40min, centrifuge, wash and dry, then bake at 600°C for 2h to prepare WO 3 The powder is ground and passed through a 120-mesh sieve for later use. The prepared catalyst powder and silica sol 1 mg: 1 μL were mixed and ultrasonically dispersed to form a uniform suspension, which was evenly coated on the surface o...

Embodiment 3

[0031] The composition of the reaction system described in Example 2 is the same, and the electric potential is recorded with a computer connected to a data collector under visible light and dark conditions respectively during operation. Figure 5 They are the power generation of the system at pH 2, 5, 7, and 10 respectively. Under neutral conditions, the battery potential is 0.7V. In acidic and alkaline solutions, the power generation effect of the system is further improved to about 0.9V; the reactor battery The potential diagram of the battery under the condition of avoiding light under the condition of pH 2-10 is maintained at about 0.5V, and the stability is better during the operation of pH=2 and 7 ( Image 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com