Double-layer anti-explosion fire extinguisher

A fire extinguisher and double-layer technology, applied in the field of double-layer explosion-proof fire extinguishers, can solve the problems of unscientific technology, shortened service life of the cylinder, and high cost, and achieve the effects of safe and reliable structure, safe and reliable cost, and scientific manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

[0029] In this embodiment, it should be understood that the terms "middle", "upper", "lower", "top", "right side", "left end", "above", "back", "middle", etc. The indicated orientation or positional relationship is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention, rather than indicating or implying that the referred device or element must have a specific orientation, be constructed and operated in a specific orientation , and therefore cannot be construed as a limitation of the present invention.

[0030] In addition, in this specific embodiment, if the connection or fixing method between the components is not specified in particular, the connect...

Embodiment 1

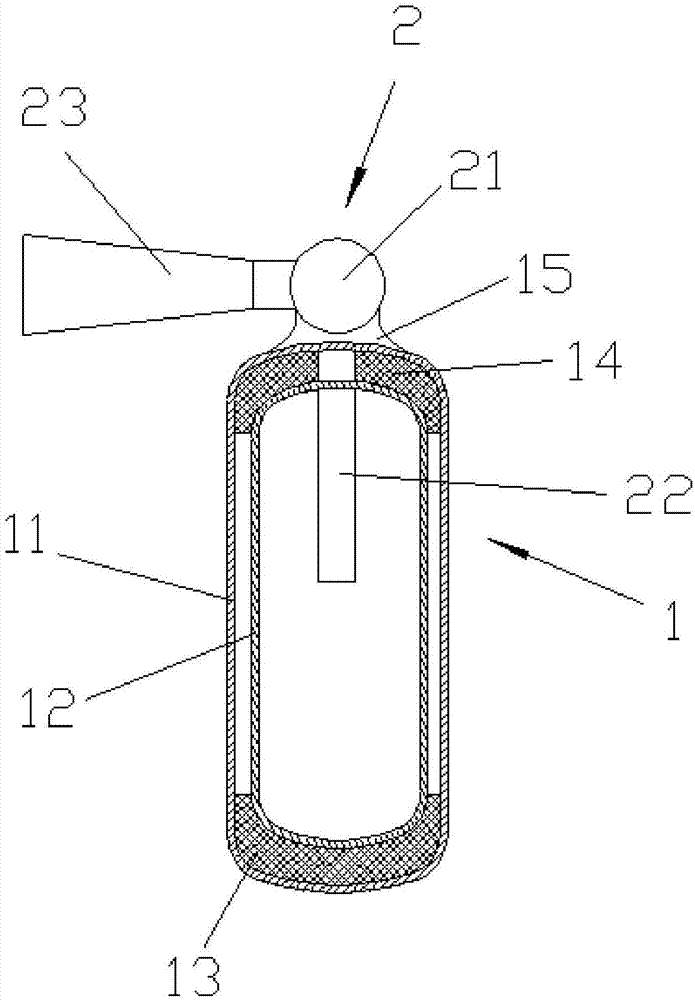

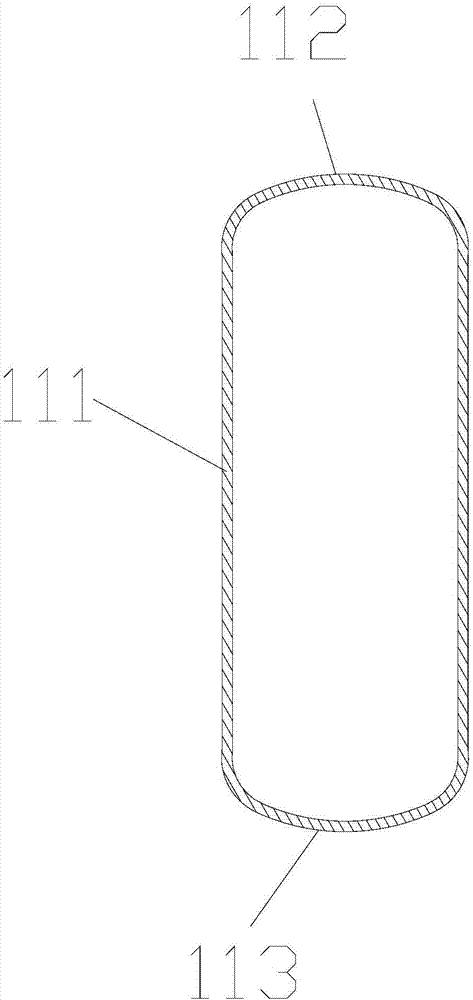

[0032] A double-layer explosion-proof fire extinguisher, such as figure 1 As shown, it includes a bottle body 1, and a valve seat 2 that is arranged on the upper end of the bottle body 1 and communicates with the bottle body 1 by screwing. cylinder 12, the upper end of the outer cylinder 11 is also provided with a steel ring 15 welded to the upper head 112 for supporting the valve seat 2. Such as figure 2As shown, the outer cylinder 11 includes an outer cylinder body 111, and an upper head 112 arranged above the outer cylinder body 111 and fixed by welding with the outer cylinder body 111 for sealing, and arranged below the outer cylinder body 111, And the lower head 113 used for sealing is fixed with the outer cylinder body 111 by welding. The structure of the inner cylinder 12 is consistent with that of the outer cylinder 11 . The bottom of the inner cylinder 12 is provided with a lower pedestal 13, and the top of the inner cylinder 12 is provided with an upper pedestal ...

Embodiment 2

[0048] A double-layer explosion-proof fire extinguisher, such as figure 1 As shown, it includes a bottle body 1, and a valve seat 2 that is arranged on the upper end of the bottle body 1 and communicates with the bottle body 1 by screwing. cylinder 12, the upper end of the outer cylinder 11 is also provided with a steel ring 15 welded to the upper head 112 for supporting the valve seat 2. Such as figure 2 As shown, the outer cylinder 11 includes an outer cylinder body 111, and an upper head 112 arranged above the outer cylinder body 111 and fixed by welding with the outer cylinder body 111 for sealing, and arranged below the outer cylinder body 111, And the lower head 113 used for sealing is fixed with the outer cylinder body 111 by welding. The structure of the inner cylinder 12 is consistent with that of the outer cylinder 11 . The bottom of the inner cylinder 12 is provided with a lower pedestal 13, and the top of the inner cylinder 12 is provided with an upper pedestal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com