In-situ observation device and observation method for crystal growth based on tiny droplets

A micro-droplet and crystal growth technology, which is applied in measuring devices, testing crystals, and material analysis through optical means, can solve the problems that the crystal growth process is not deep enough, and it is impossible to observe the growth process in situ, and achieve convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

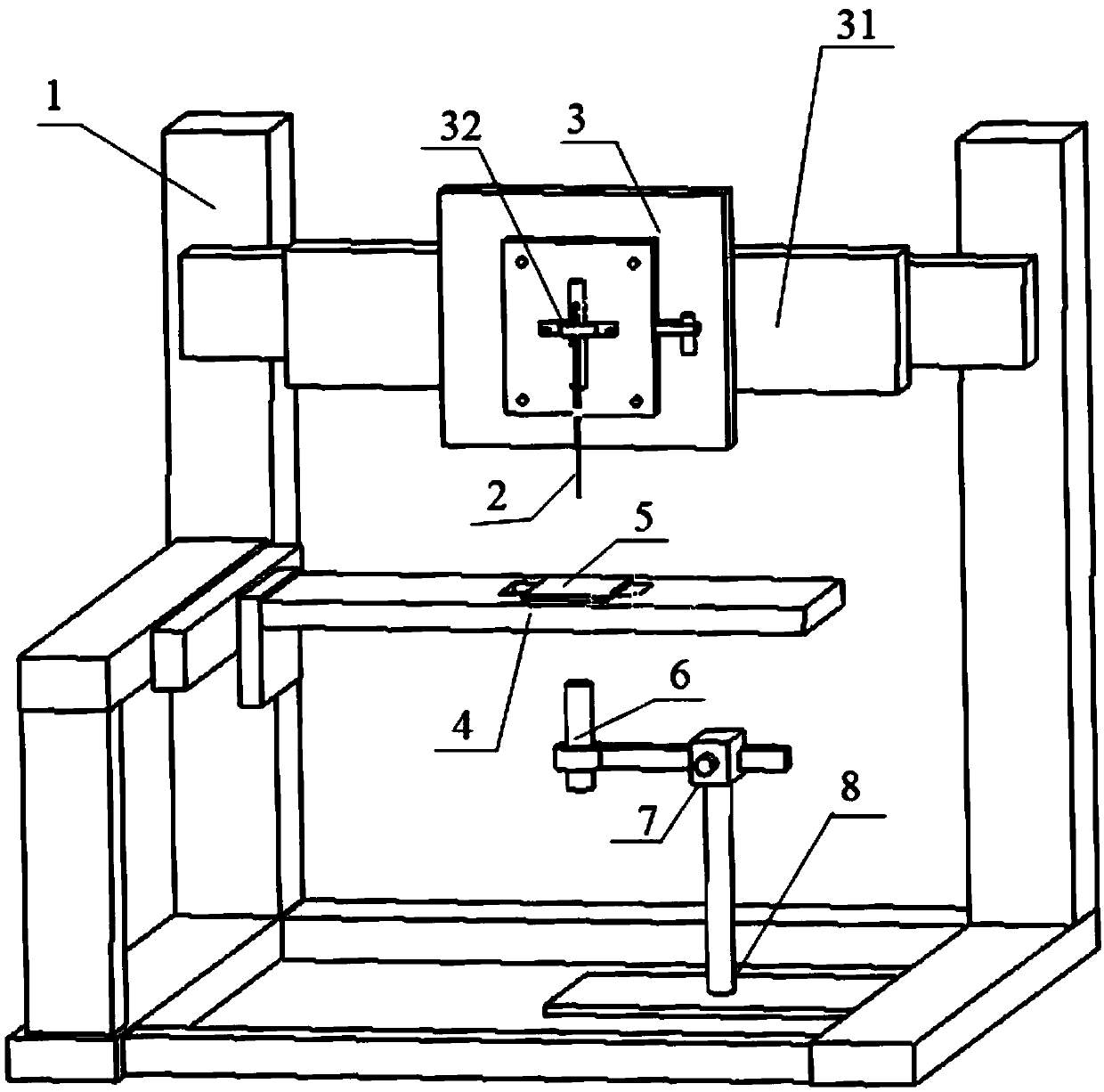

[0035] Such as figure 1 As shown, an in-situ observation device for crystal growth includes a bracket 1 , a droplet generation and control unit, a droplet carrying platform 4 , an observation recording unit and an observation mirror bracket 8 . The droplet generation and control device includes a microdroplet 2 , a droplet generation controller and a dropper holder 3 . The micro-dropper 2 is fixed on the top of the bracket 1 by a dropper holder 3 . The middle part of the droplet carrying platform 4 is provided with a through hole for placing a transparent slide glass 5 , and the slide glass 5 is located under the microdrop tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com