Monitoring support and intelligent monitoring system

A technology of intelligent monitoring and support, applied in the direction of measuring devices, measuring instrument components, force/torque/power measuring instruments, etc., can solve the problems of inconvenient maintenance and replacement of sensing elements, achieve long-term monitoring and prolong service life , Solve the effect of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

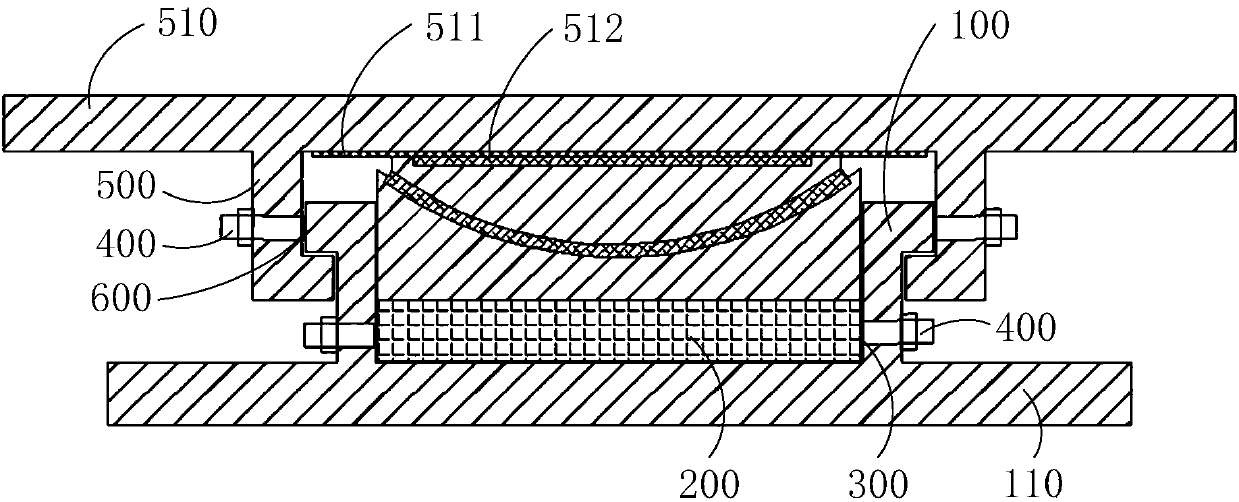

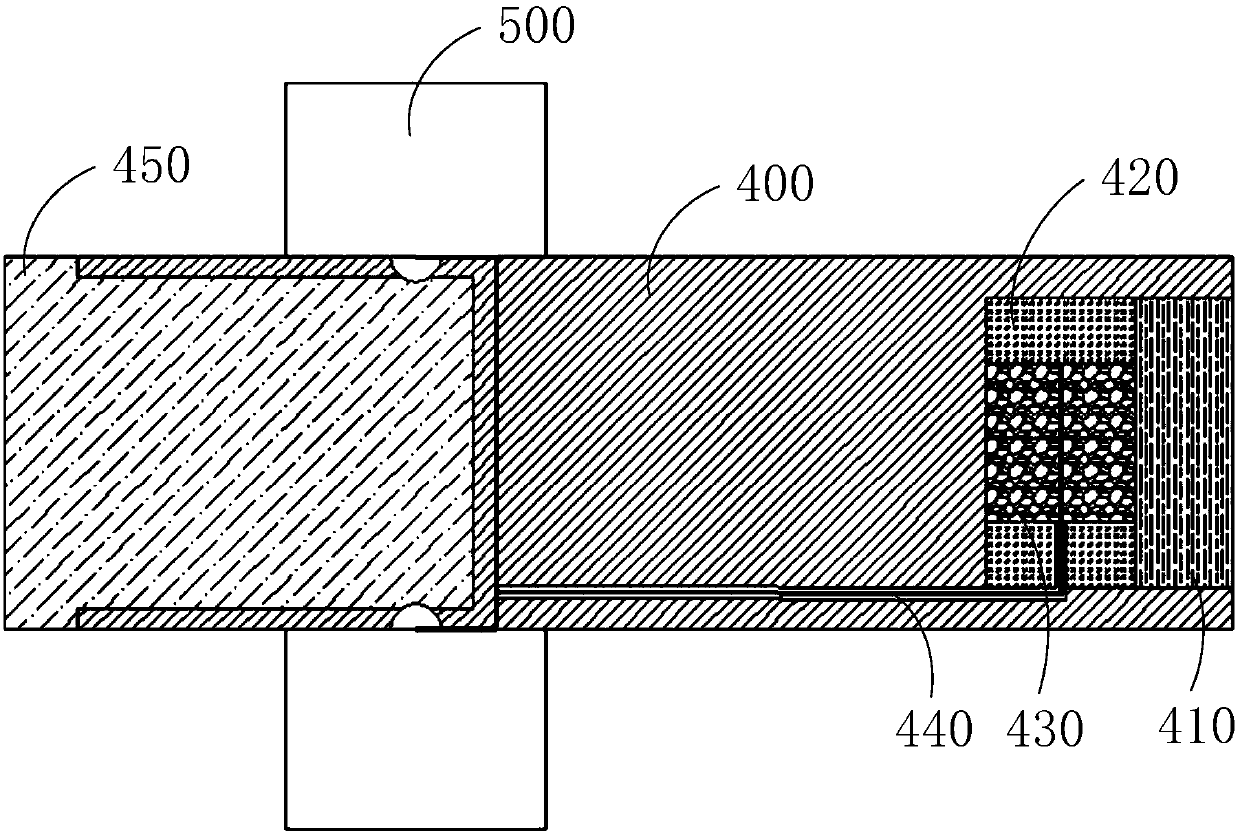

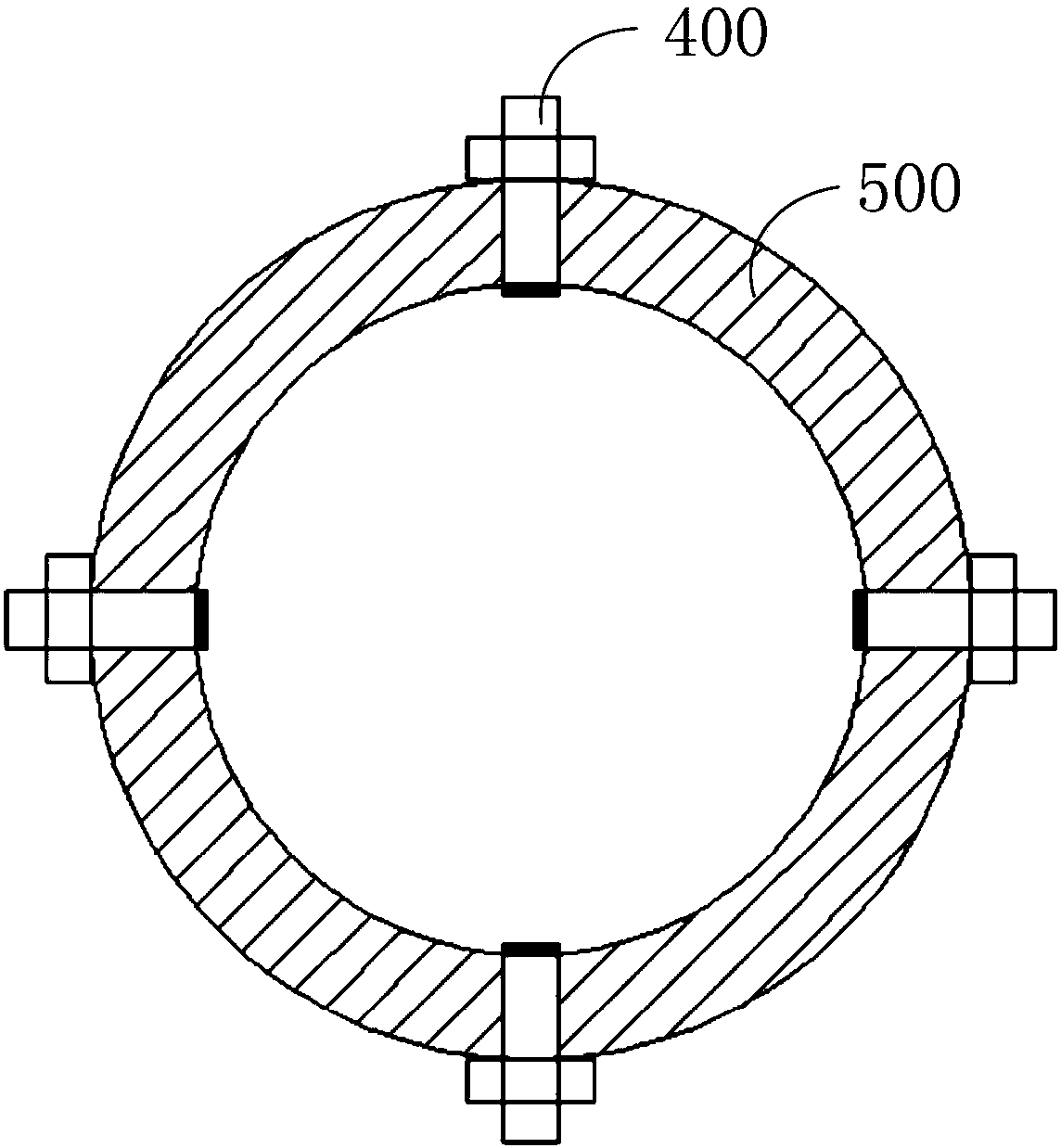

[0032] figure 1 A schematic diagram of the internal structure of the monitoring support provided by the embodiment of the present invention, such as figure 1 As shown, the monitoring support provided by the embodiment of the present invention includes: the support basin ring 100, the force measuring plate 200 and the vertical load sensing element 300, the force measuring plate 200 is made of elastic material, and is arranged on the support basin ring Within 100;

[0033] A detachable auxiliary component 400 is connected to the side wall of the support basin ring 100, the auxiliary component 400 runs through the side wall of the support basin ring 100, and the vertical load sensing element 300 is arranged on the side wall of the support basin ring 100 of the auxiliary component 400 The inner end is in contact with the side wall of the force plate 200.

[0034] The lower end of the bearing basin ring 100 is provided with a bearing base plate 110, and the bearing basin ring 100...

Embodiment 2

[0071] Another object of the embodiments of the present invention is to provide an intelligent monitoring system.

[0072] The intelligent monitoring system provided by the embodiment of the present invention includes the monitoring support of the above technical solution.

[0073] The hardware of the intelligent monitoring system includes multi-channel sensor signal adaptation modules, data acquisition boards, etc.; the software of the intelligent monitoring system mainly consists of three parts: data acquisition driver package, application programming interface, and virtual instrument.

[0074]The intelligent monitoring system sets the corresponding threshold value. During the monitoring process, when the load sensed by the sensor exceeds this threshold value, the system starts to automatically monitor, store relevant data and issue a reminder to the management personnel.

[0075] The monitoring support in the intelligent monitoring system provided by the embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com