Optimizing method of air and flue gas system control after desulfurization and denitrification transformation of thermal power generating unit

A thermal power unit, desulfurization and denitrification technology, applied in the direction of combustion method, combustion control, air supply adjustment, etc., can solve the problem of no targeted research on the control of the wind and smoke system, achieve simple on-site commissioning process, reduce labor intensity, Effects that are easy to realize in engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

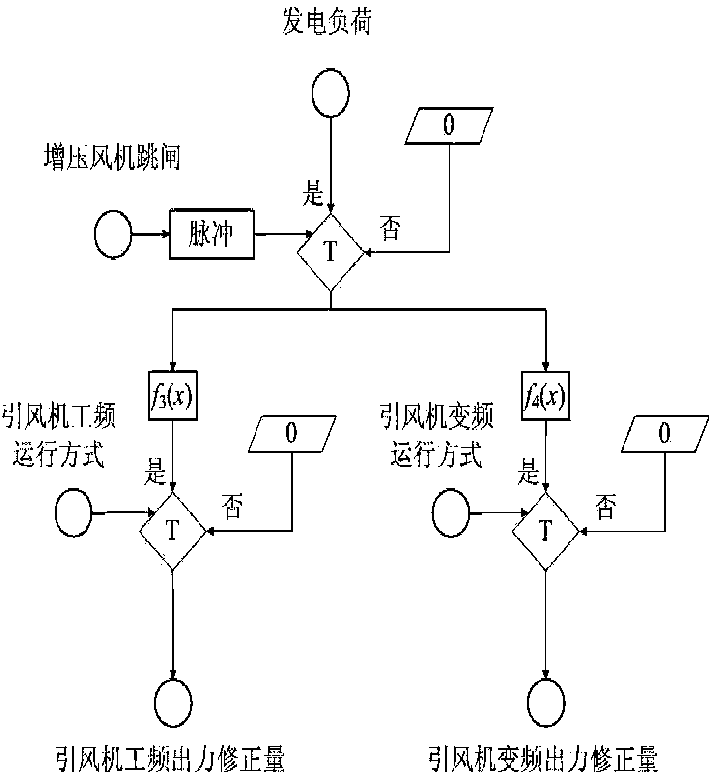

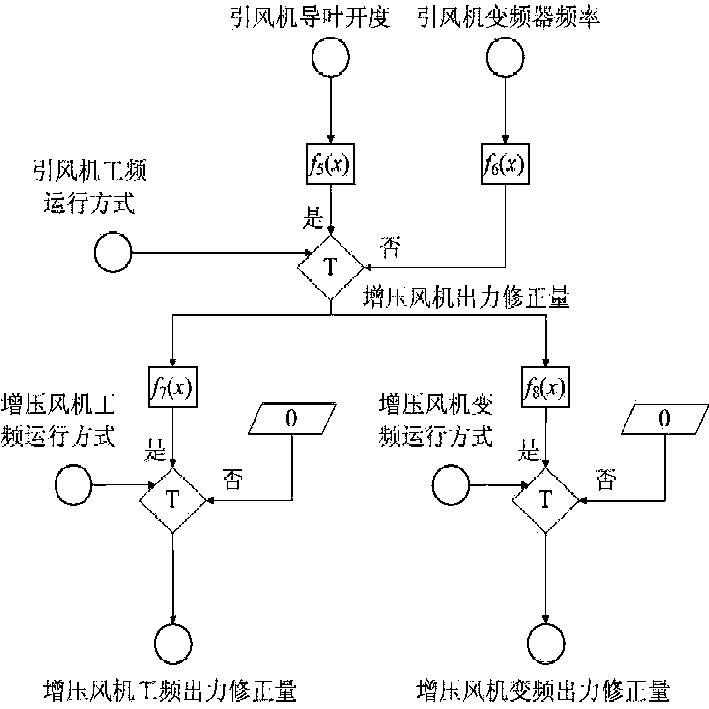

[0024] The invention is a control optimization method for the wind and smoke system after desulfurization and denitrification transformation of thermal power units, such as Figure 4 shown, including the following steps:

[0025] Step 1: Add the following control loops and loop interfaces in the control logic configuration of the DCS of the thermal power unit distributed control system: the oxygen amount correction control loop and loop interface after the desulfurization and denitrification transformation of the thermal power unit, and the second Secondary damper opening correction control circuit and circuit interface, induced draft fan output correction control circuit and circuit interface after thermal power unit desulfurization and denitrification transformation, booster fan output correction control circuit and circuit interface after thermal power unit desulfurization and denitrification transformation;

[0026] Step 2: Add the following interlocking control logic in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com