Coal mine gas extraction hole plugging device

A plugging device and coal mine gas technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve problems such as threats to the life safety of operators, damage to the underground working environment, and easy foaming of polyurethane to achieve good plugging effect, Simple structure, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

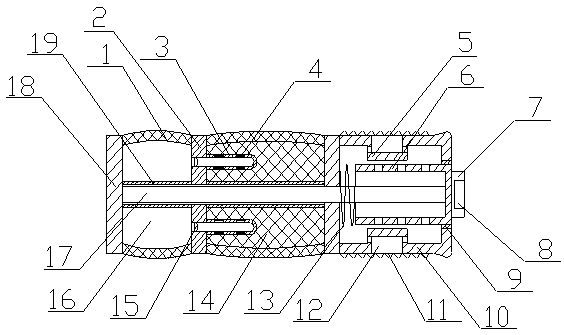

[0025] A coal mine gas drainage hole sealing device of the present invention is realized in this way. When using, when sealing the coal mine gas drainage hole, firstly insert the elastic sleeve (1) into the coal mine gas drainage hole, and then use The hex wrench rotates the rotating block (7), the rotating block (7) drives the sliding cylinder (6) to rotate, the sliding cylinder (6) drives the main cylinder (10) to rotate through the guide sleeve (9), and then the main cylinder (10) is screwed into In the coal mine gas drainage hole, at this time, the main cylinder (10) seals the coal mine gas drainage hole. As time goes by, the gas concentration in the hole increases continuously, and the gas in the hole enters the two holes on the main cylinder (10). air guide slots (12), and then flow into the main cylinder (10) through the air inlet holes on the corresponding cover plate (5), and then enter the sliding cylinder (6) through multiple through holes on the sliding cylinder (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com