Preparation method of octahydro dipyrroloquinoline compound

A technology for octahydrodipyrrole and compound, which is applied in the field of preparation of octahydrodipyrroloquinoline compounds, can solve the problems of pollution, high cost of chiral phosphoric acid and silver catalyst, and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 3-methoxyphenyl-2-pyrrolidinyl-1-ylphenylmethanol As an example, to prepare The reaction process is shown in Table 1,

[0023] 0.2mmol After being mixed with catalyst (20mol%), add in the solvent of 2ml, react under the condition of 60 ℃, reaction time is as shown in the table, check the productive rate of final product, the result is shown in table 1.

[0024] Table 1: Reaction conditions and results

[0025]

[0026] In 17 in Table 1, DCE is dried first, and the drying method is: add CaH to each liter of DCE 2 5g, distilled at 130°C; b : Column chromatography separation yield.

Embodiment 2

[0028] raw material: 3-methoxyphenyl-2-pyrrolidinyl-1-ylphenylcarbinol

[0029] Reaction conditions: Toluene, 60°C, PA (20%)

[0030] Product: Chemical formula: C 36 h 38 N 2 o 2

[0031] Exact molecular weight: 530.2933

[0032] Molecular weight: 530.7120

[0033] Structural formula:

[0034] Yield: 96%, dr 5:1.

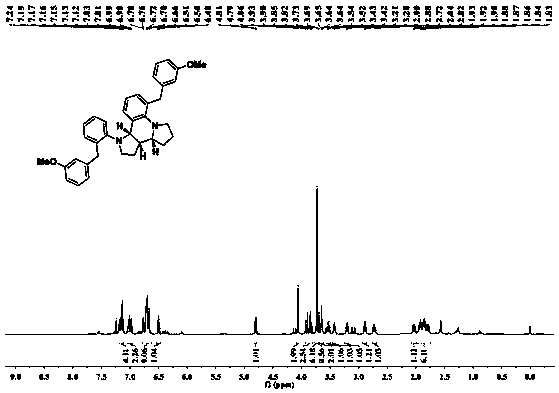

[0035] 1 H NMR (500MHz, CDCl 3 )δ7.15(dt, J=14.9, 7.7Hz, 4H), 7.04–6.96(m, 2H), 6.79–6.62(m, 9H), 6.50(t, J=7.5Hz, 1H), 4.80(d ,J=8.4Hz,1H),4.06(s,2H),3.94–3.81(m,3H),3.74(d,J=12.0Hz,6H),3.65(dd,J=10.2,5.4Hz,2H) ,3.53(dd,J=16.1,7.9Hz,1H),3.42(td,J=8.5,4.0Hz,1H),3.20(td,J=8.7,2.7Hz,1H),2.89(dd,J=15.8 ,8.4Hz,1H),2.73(td,J=10.6,2.9Hz,1H),2.07–2.00(m,1H),1.98–1.74(m,6H); 13 C NMR (125MHz, CDCl 3 )δ159.65,159.56,150.33,145.68,143.65,143.38,137.12,131.00,130.68,129.17,129.09,127.94,127.78,127.16,127.01,123.26,122.30,121.81,121.24,118.45,114.95,114.49,111.09,111.02,63.78 ,59.70,55.12,55.07,53.67,52.26,42.71,39.90,37.45,29.07,25.84,24.50; HRMS(ESI):calcd ...

Embodiment 3

[0037] raw material: 4-Methoxyphenyl-2-pyrrolidin-1-ylphenylcarbinol

[0038] Reaction conditions: Toluene, 60°C, PA (20%)

[0039] Product: Chemical formula: C 36 h 38 N 2 o 2

[0040] Exact molecular weight: 530.2933

[0041] Molecular weight: 530.7120

[0042] Structural formula:

[0043] Yield: 92%, dr 5:1.

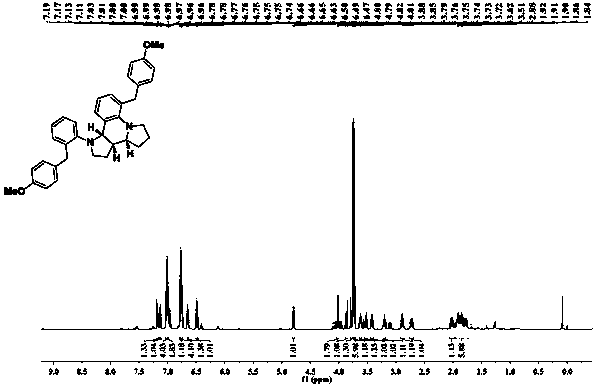

[0044] 1 H NMR (500MHz, CDCl 3 )δ7.20–7.15(m,1H),7.12(d,J=7.2Hz,1H),7.01(dd,J=9.0,5.2Hz,4H),6.99(dd,J=5.3,2.0Hz,2H ),6.80–6.78(m,1H),6.78–6.73(m,4H),6.65(dd,J=9.1,3.7Hz,1H),6.49(t,J=7.5Hz,1H),4.79(d, J=8.5Hz, 1H), 4.02(d, J=5.2Hz, 2H), 3.88(dd, J=10.6, 7.7Hz, 1H), 3.80–3.76(m, 1H), 3.74(d, J=6.0 Hz, 6H), 3.72(d, J=5.3Hz, 1H), 3.65–3.60(m, 1H), 3.52(dd, J=16.3, 7.8Hz, 1H), 3.42(td, J=8.6, 4.1Hz ,1H),3.23–3.18(m,1H),2.89(dt,J=8.7,6.9Hz,1H),2.72(qd,J=8.3,3.2Hz,1H),2.06–1.98(m,1H), 1.96–1.73(m,6H); 13 C NMR (125MHz, CDCl 3 )δ157.73,157.71,150.23,145.76,137.81,133.98,133.85,130.94,130.62,130.23,129.65,127.72,127.69,127.07,123.27,122.27,118.44,113.72,113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com