Double-shaft input hybrid power system and drive method

A technology of a hybrid power system and a driving method, which is applied to the layout of multiple different prime movers of a hybrid vehicle, a power plant, and a general power plant, and can solve problems such as limited use range, inability to charge at idle speed, and increased cost resources, etc. problems, to achieve the effect of increasing the scope of use, ensuring power, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

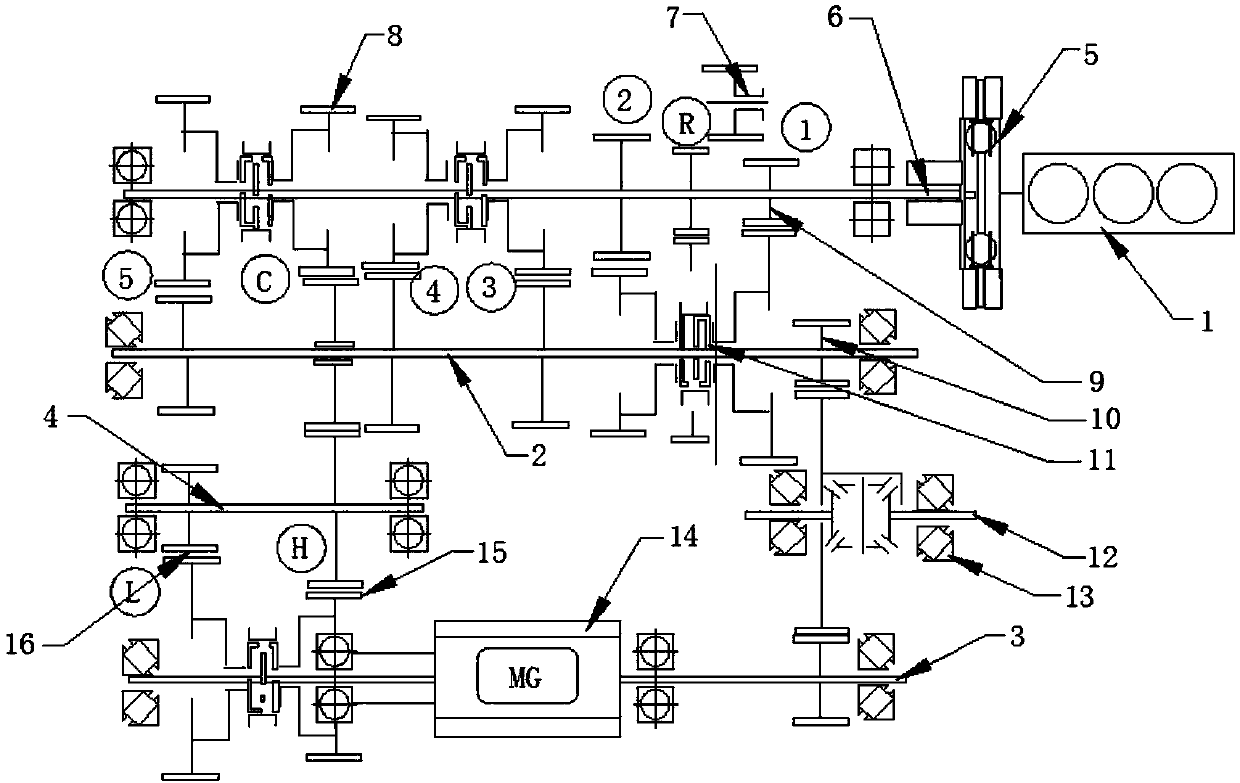

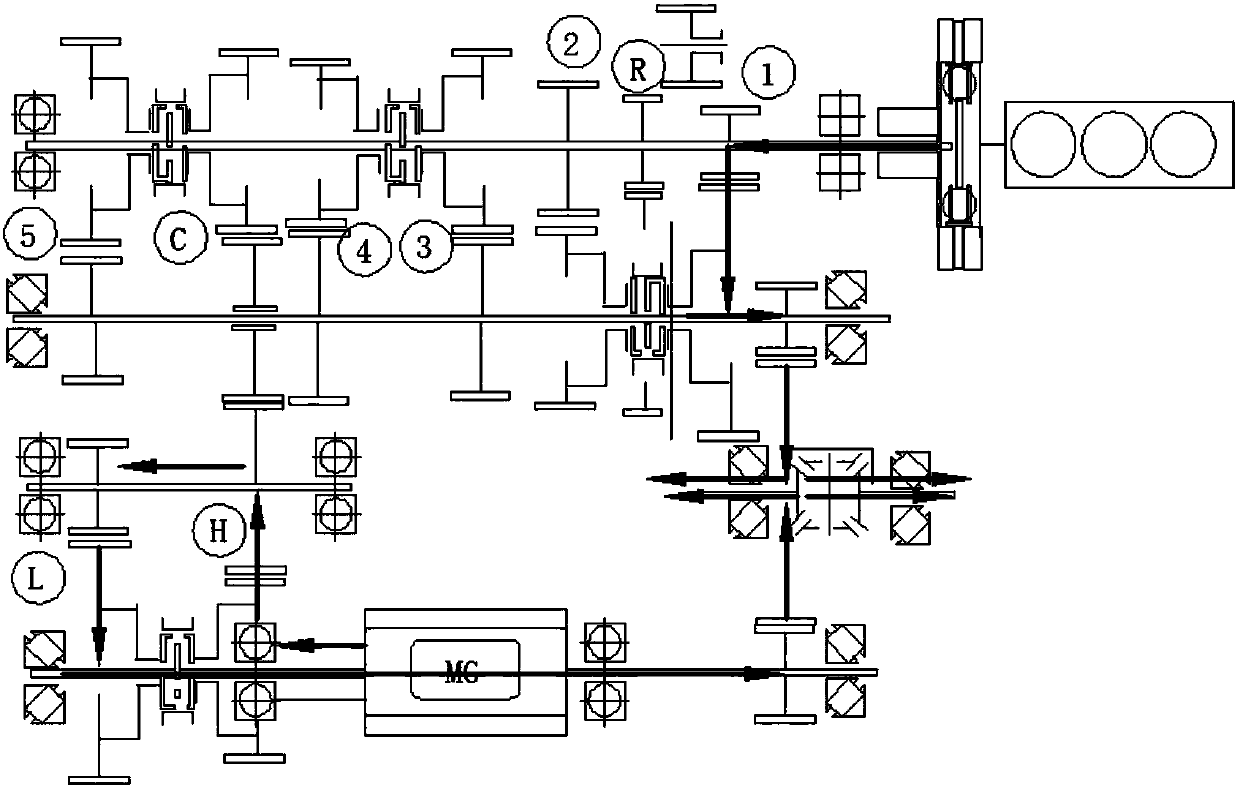

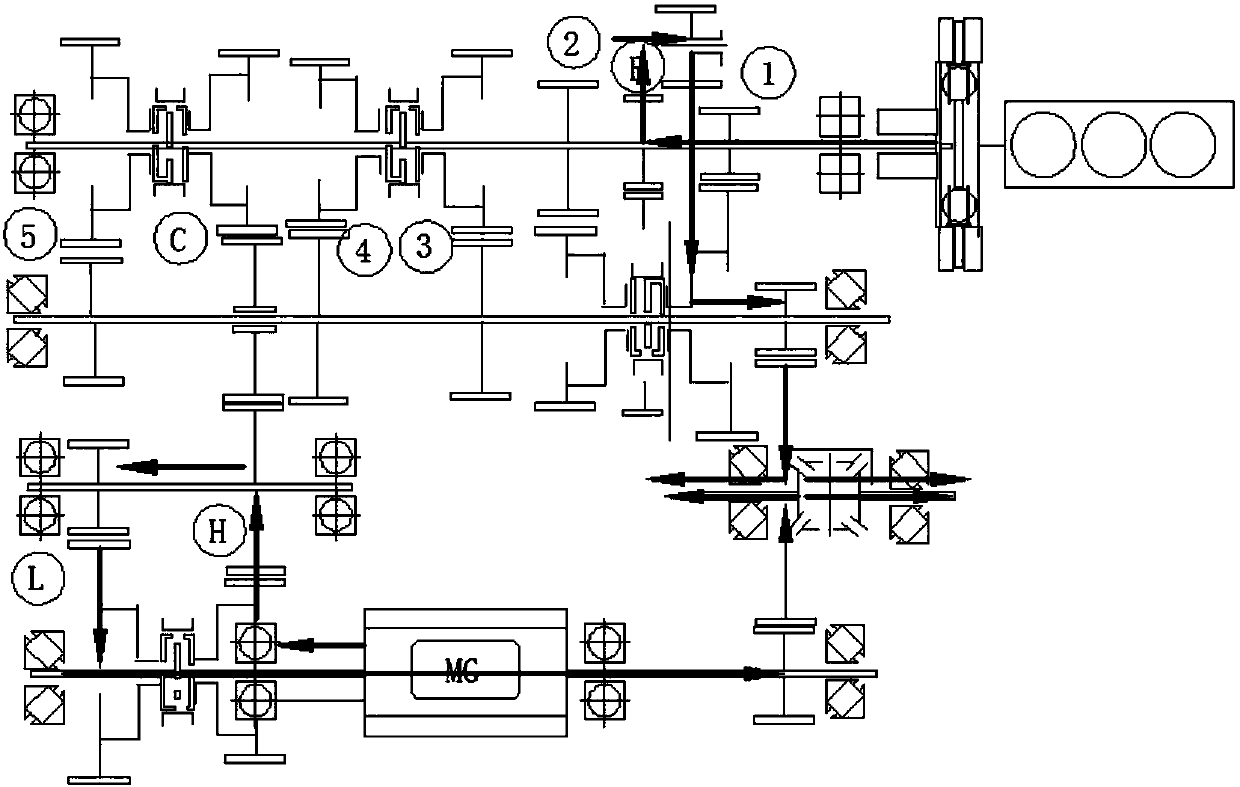

[0030] like Figure 1-4 As shown, the present invention provides a two-shaft input hybrid power system and a driving method, including an engine 1, two shafts 2, P3 shaft 3 and three shafts 4, and the two shafts 2, P3 shaft 3 and three shafts 4 are all transmitted by the engine 1 connection, which is characterized in that one side of the engine 1 is connected with a shaft 6, a clutch 5 is installed between the first shaft 6 and the engine 1, a rotating gear 7 and a C gear 8 are respectively installed on the first shaft 6, and one end of the second shaft 2 A main reducer 10 is installed, a synchronizer 11 is installed on one side of the main reducer 10, a gear gear 9 is installed between the first shaft 6 and the second shaft 2, and L Gear gear 16 and H gear gear 15, motor 14 is installed on P3 shaft 3, half shaft 12 is connected between P3 shaft 3 and two shafts 2, differential 13 is installed on the half shaft 12, gear position The gears are divided into 1st gear, 2nd gear, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com