A roller hearth tunnel heating furnace

A technology of heating furnace and roller hearth type, applied in the field of metallurgy, can solve the problems of shortening the length of heating furnace, reducing equipment cost, length of heating furnace, etc., and achieve the effect of improving billet picking efficiency, reducing equipment cost and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

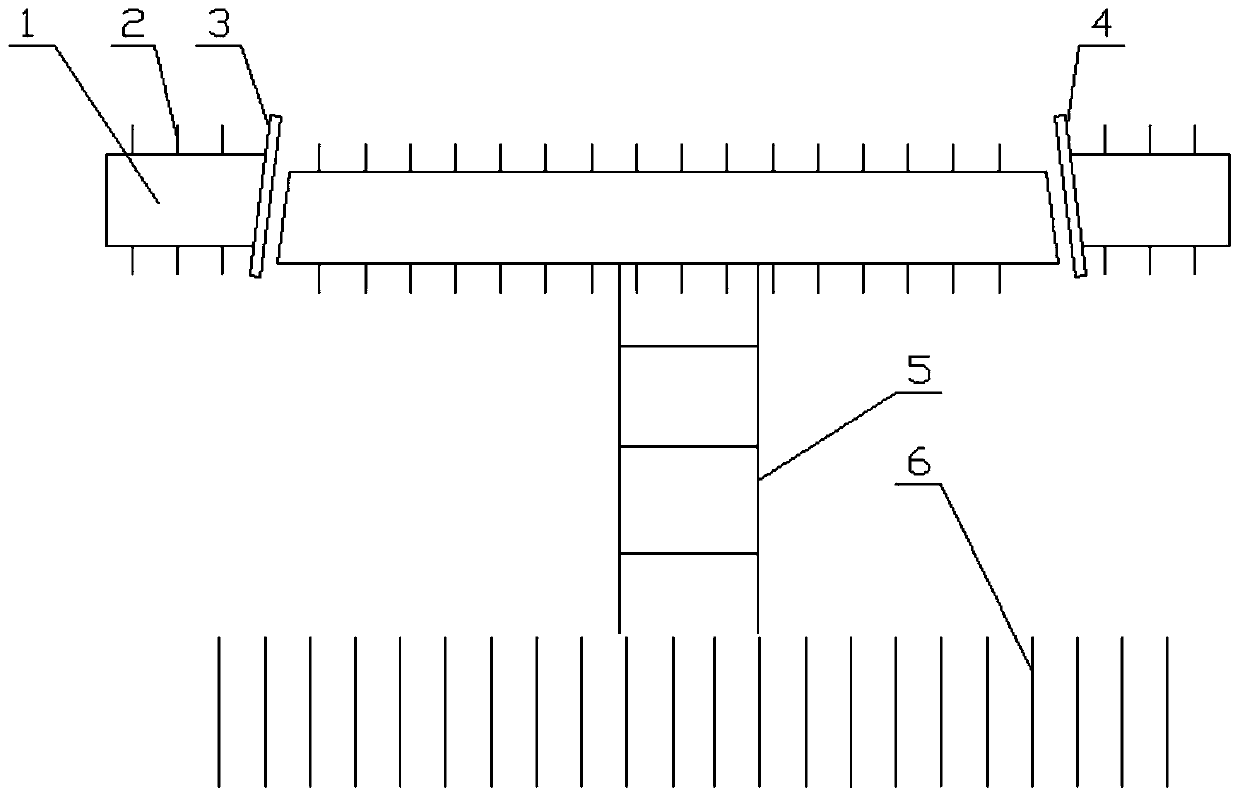

[0041] The embodiment of the present application provides a roller hearth tunnel heating furnace, which solves or partially solves the technical problems in the prior art that the heating furnace is long, and there is a risk of casting slab deviation or even bumping out of the furnace wall. By setting the furnace body, The roller hearth tunnel heating furnace composed of multiple burners, sealing devices, the first automatic flame cutting gun and the second automatic flame cutting gun can significantly shorten the length of the heating furnace and greatly reduce the cost of casting slab while ensuring the heating effect. The probability of deviation in the furnace significantly reduces the technical effect of equipment cost.

[0042] See attached figure 1 and 2 , The application provides a roller hearth tunnel heating furnace, including: a furnace body, a plurality of burners, a sealing device 7, a first automatic flame cutting gun 3 and a second automatic flame cutting gun 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com