Automatic cleaning system used for residential photovoltaic system and judgment method

A photovoltaic system and automatic cleaning technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of manual operation safety hazards, limitations, scratches on the surface of photovoltaic modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

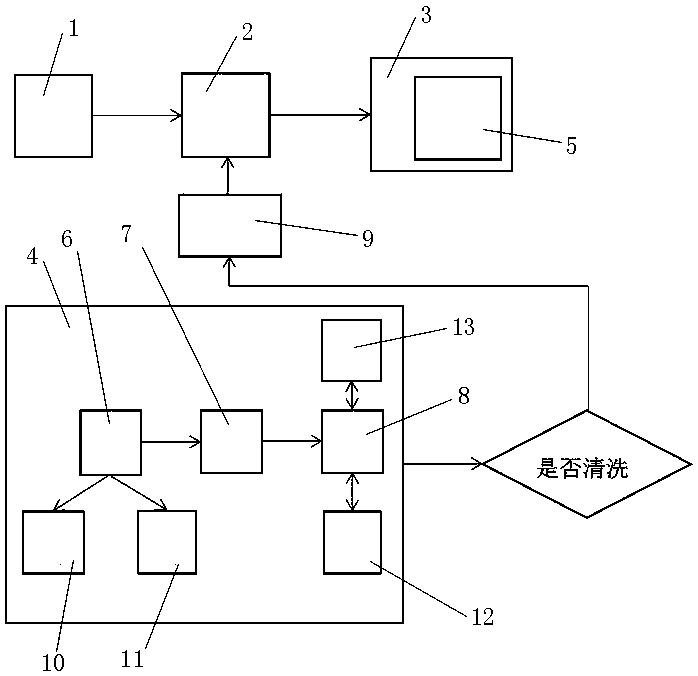

[0025] See attached picture. The automatic cleaning system of this embodiment includes a pressurizing module 2 and a spraying module 3, the spraying module includes at least one spraying head 5, the spraying head is arranged at the center of the photovoltaic module, and the spraying head can rotate freely in 360 degrees. The water source 1 is tap water, well water or natural lakes in residents’ homes. After being pressurized by the pressurization module, it is sprayed out by the injection module, so that the water droplets are evenly sprayed onto the surface of the photovoltaic module, simulating natural precipitation, and achieving the purpose of cleaning. The system also Including a control module 4, the control module includes a field sensing unit 6, a data acquisition unit 7, a background analysis unit 8 and a front-end control unit 9, the field sensing unit includes a humidity sensor 10 and an irradiance sensor 11, and the field sensor The sensing unit detects the cleanli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com