Carrier backflow type UV curing production line

An assembly line and carrier technology, applied in the direction of conveyor objects, conveyors, pre-treated surfaces, etc., can solve problems such as poor product curing effect, low work efficiency, and inconvenient use, so as to save pick-and-place time and improve Good working efficiency and curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

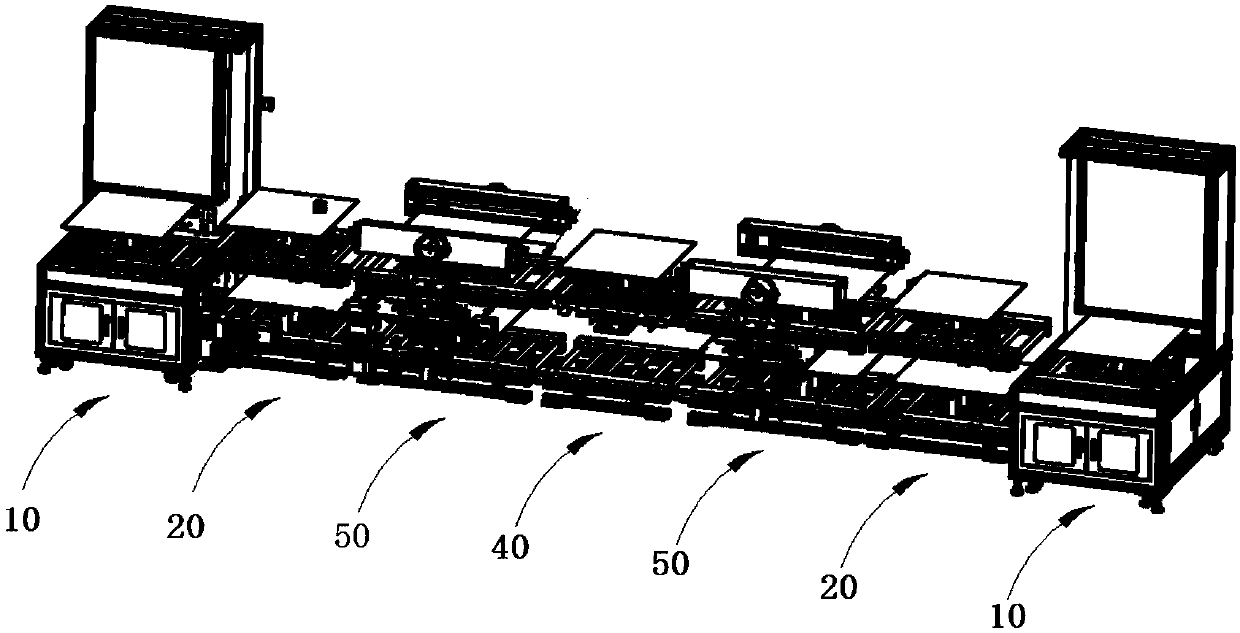

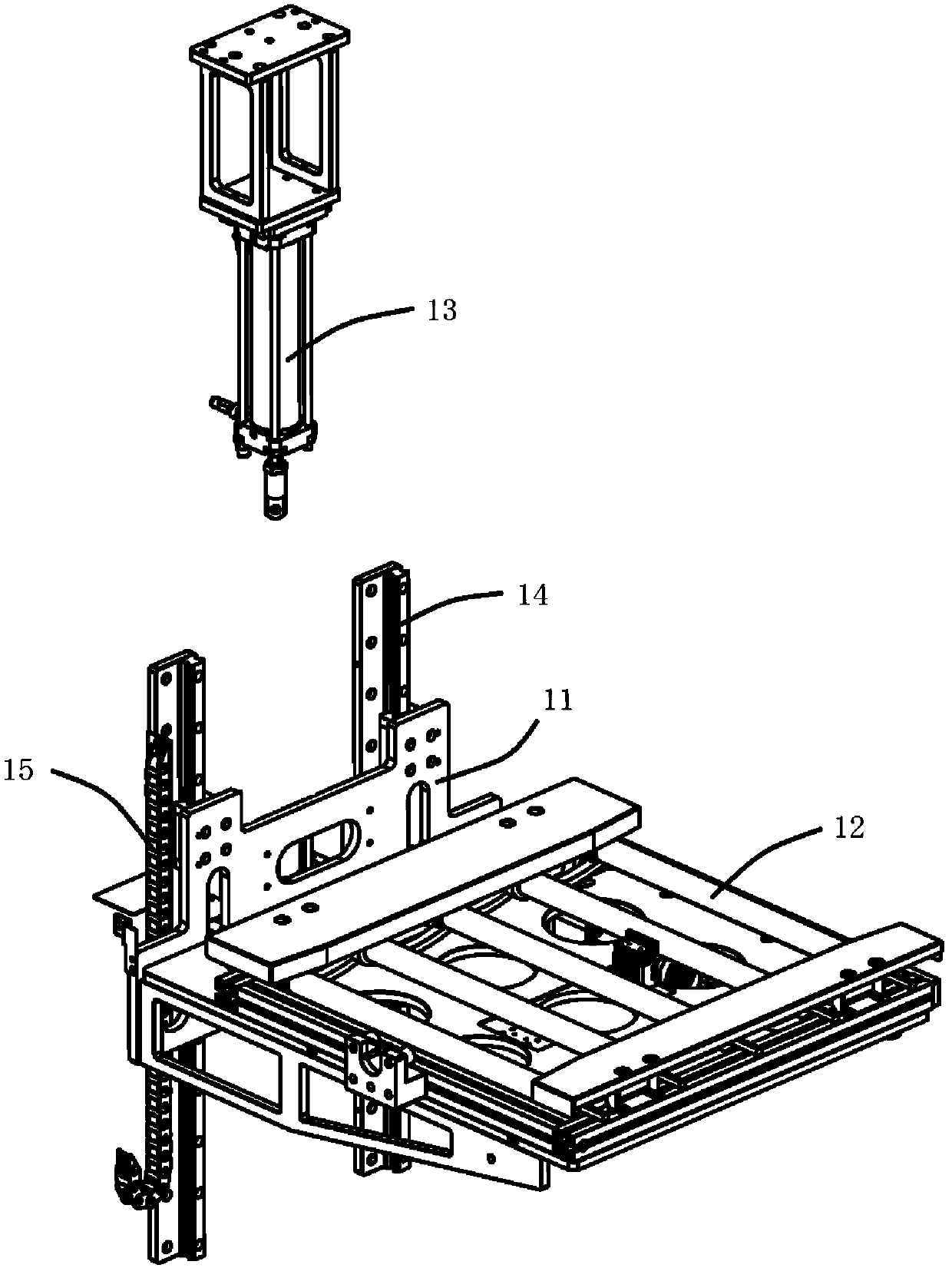

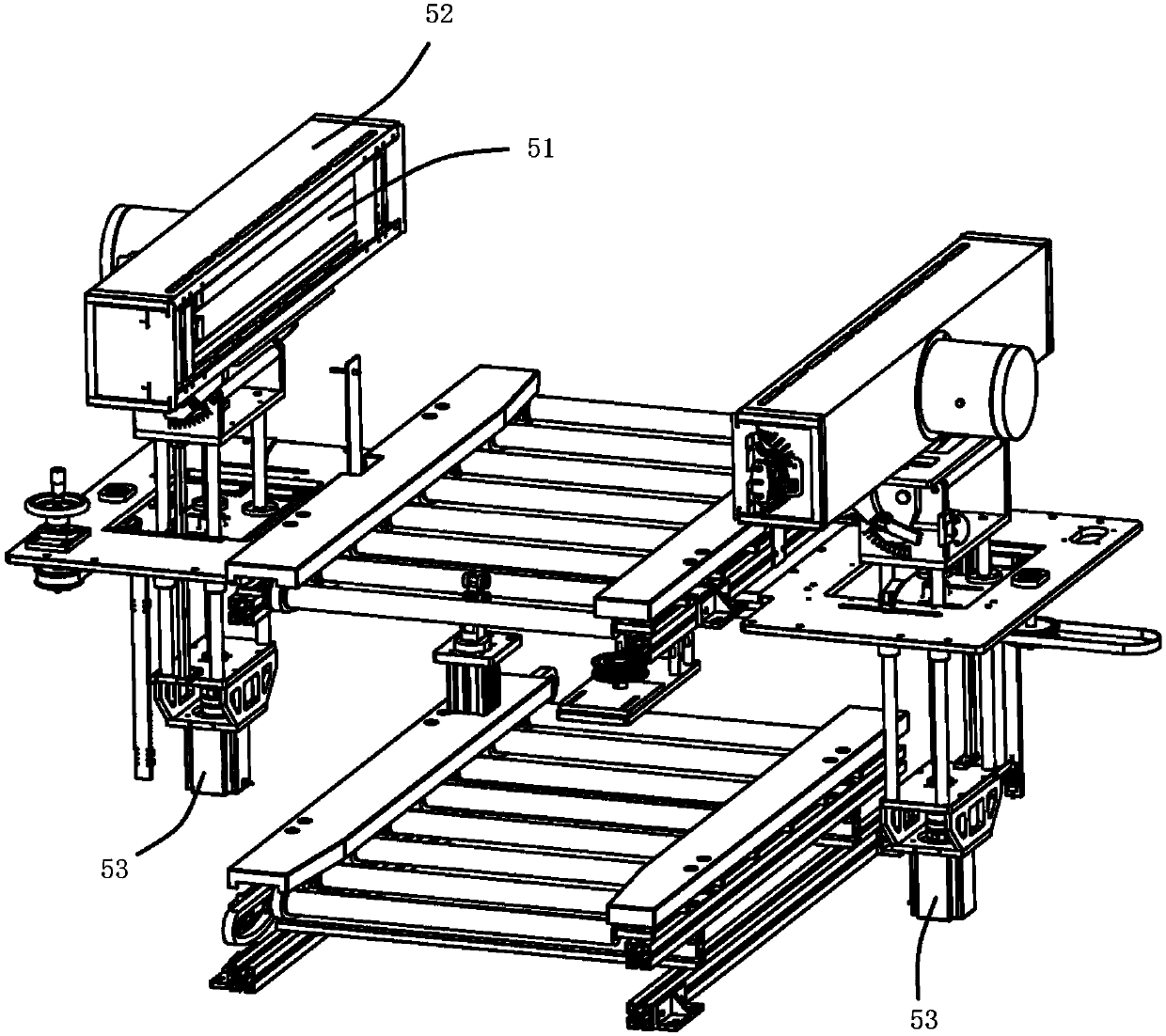

[0032] Such as Figures 1 to 5 As shown, a carrier reflow type UV curing assembly line includes a conveying device, a carrier 60 and a UV curing device 50 arranged on the conveying device for carrying products; wherein, the conveying device includes a frame, and is arranged on the frame up and down. The upper conveying device 101 and the lower conveying device 102, and the two carrier lifting and connecting machines 10 which are separately arranged at both ends of the frame and used to connect the upper conveying device 101 and the lower conveying device 102; the UV curing device 50 is arranged on the upper above the conveying device 101, and perform UV curing on the products conveyed by the upper conveying device 101. In the carrier reflow type UV curing line of the present invention, the upper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com