Automatic production device of steamed sponge cake and production method thereof

An automatic production and cake making technology, which is applied in metal processing, grain processing, food forming, etc., can solve the problems of glutinous rice smashing and stirring evenly, uneven nutrition of cake making, and low resource utilization rate, so as to avoid human injury and improve nutrition distribution Uniform, productivity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

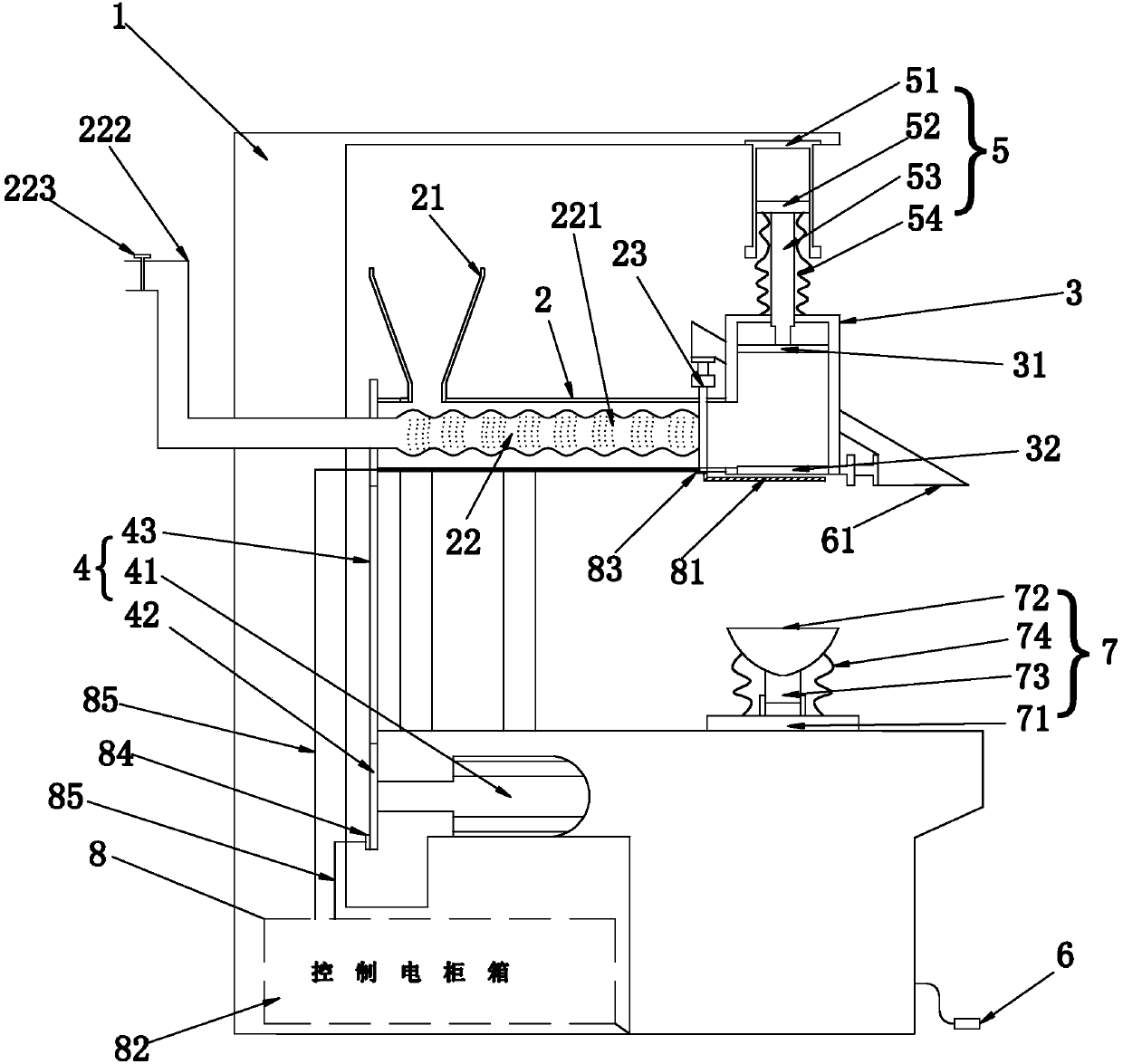

[0030] An automatic production device for cakes, in a specific embodiment of the present invention, includes a frame 1, an extruding tube 2 and a hopper 21 connected to the extruding tube 2, and the extruding tube 2 is provided with a drive assembly 4 to drive it to rotate. Screw rod 22, one end of extruding tube 2 is connected with storage tank 3, and the inner wall of described storage tank 3 is slidably connected with extruding block 31 driven by conveying assembly 5, and the bottom of storage tank 3 is set as opening And the opening is provided with a discharge valve 32 , and the connection between the extruded pipe 2 and the storage tank 3 is provided with a feed valve 23 .

[0031] In a specific embodiment of the present invention, the transmission assembly 4 includes a motor 41 driven by the control unit 8 and a pulley 42 connected to the output end of the motor 41, and the pulley 42 is away from the storage tank 3 through the conveyor belt 43 and the screw 22 one end o...

Embodiment 2

[0043] Embodiment 2, the difference with embodiment 1 is

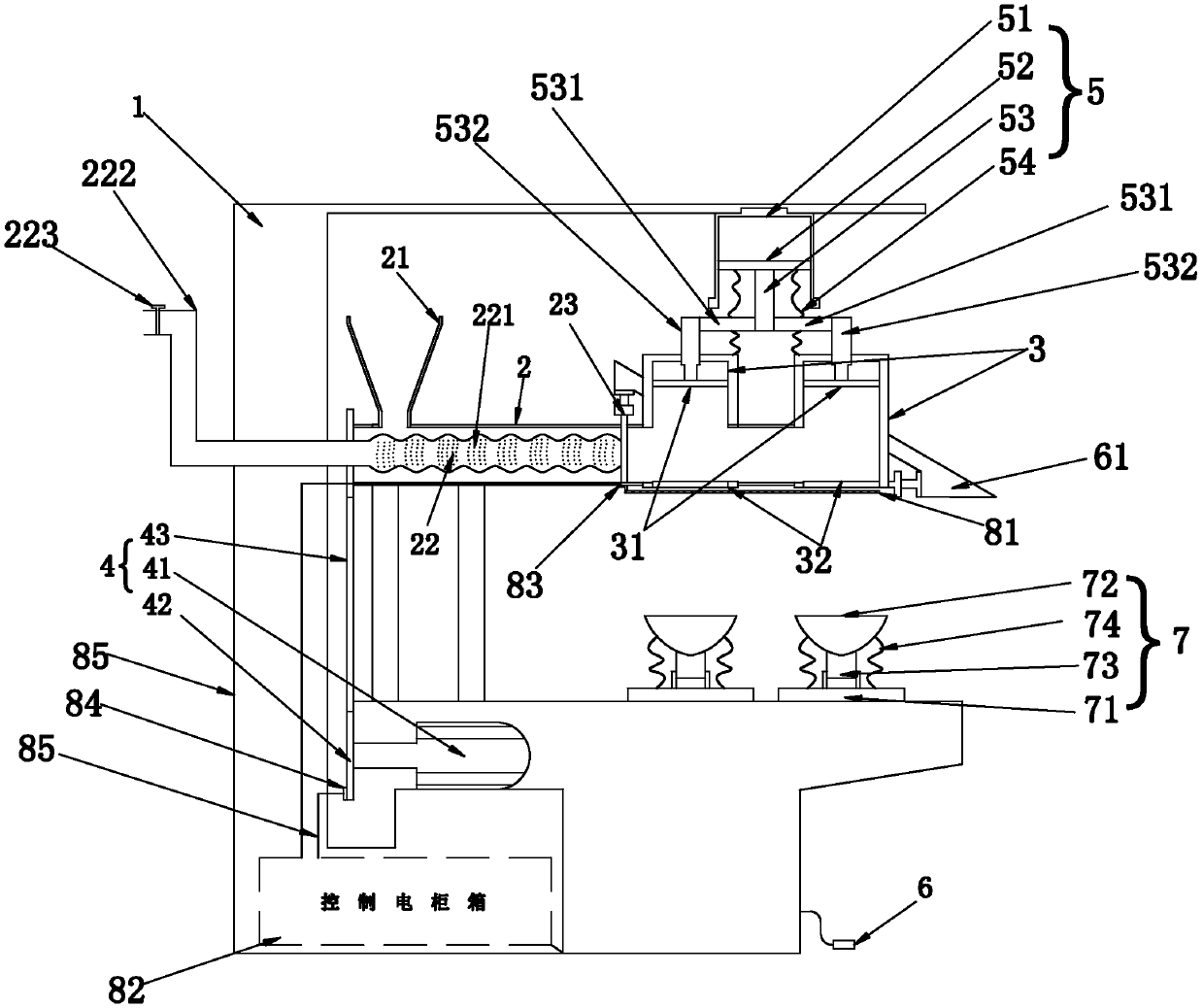

[0044] Such as figure 2 As shown, in a specific embodiment of the present invention, there may be two storage tanks 3 and two weighing devices 7 .

[0045] In a specific embodiment of the present invention, two sides of the piston rod 53 close to the bottom are respectively fixedly connected to the extruding block 31 through two first struts 531 and two second struts 532 .

[0046] By adopting the above technical scheme: setting the storage tank 3 as two can increase the output of a single production of cakes, thereby improving the efficiency of production.

Embodiment 3

[0048] An automatic production method for cakes, characterized in that: the specific steps are as follows:

[0049] (1) Material mixing: close the feeding valve, add the required material into the extrusion tube through the hopper, and the screw rotates to stir and pound the material evenly;

[0050] (2) Filling the storage tank: open the feed valve, close the discharge valve, and the screw will send the evenly stirred material into the storage tank until the storage tank is filled;

[0051] (3) Material extrusion: open the discharge valve, drive the pressure injection cylinder to push the piston rod to push the extrusion block, and extrude the material in the storage tank;

[0052] (4) Material cutting: the length sensor feeds back the length of the extruded material to the control unit, and the control unit drives the cutter to cut the material;

[0053] (5) Material receiving: the weighing device receives and weighs the cut material.

[0054] By adopting the above technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com