Container structure for long-term storage of staple food

A long-term storage, container technology, applied in applications, agricultural machinery and implements, gardening, etc., can solve the problem of inconvenient food storage and retrieval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

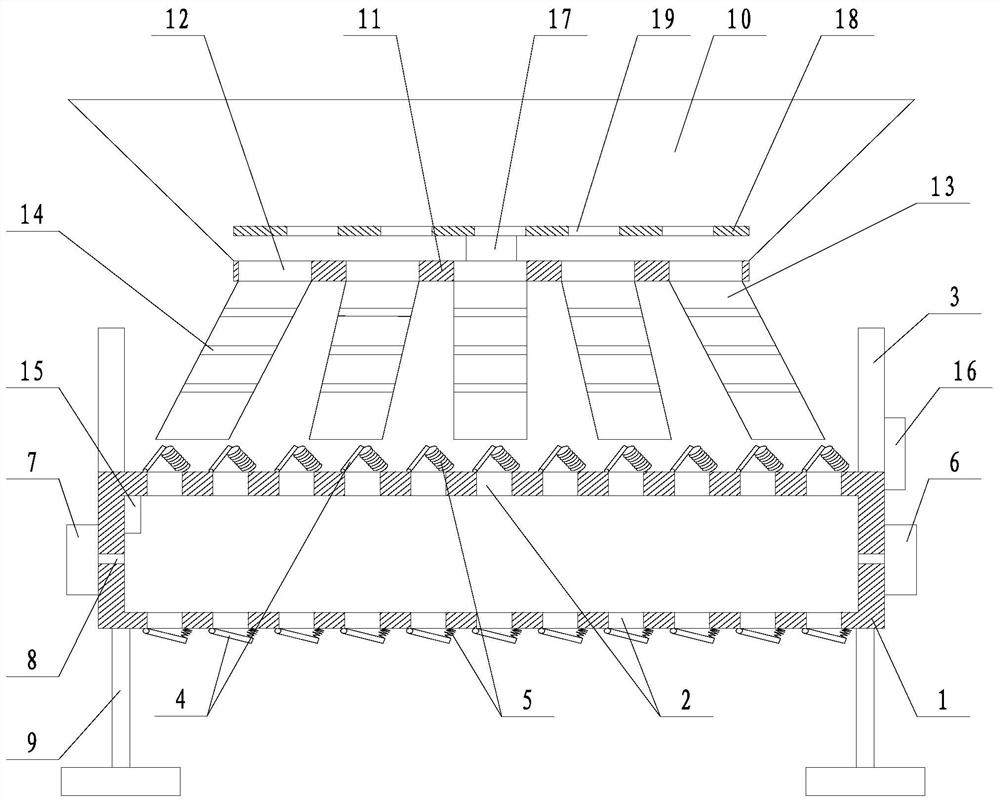

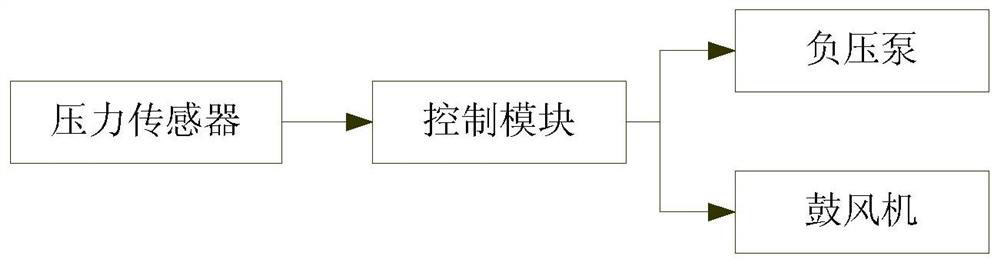

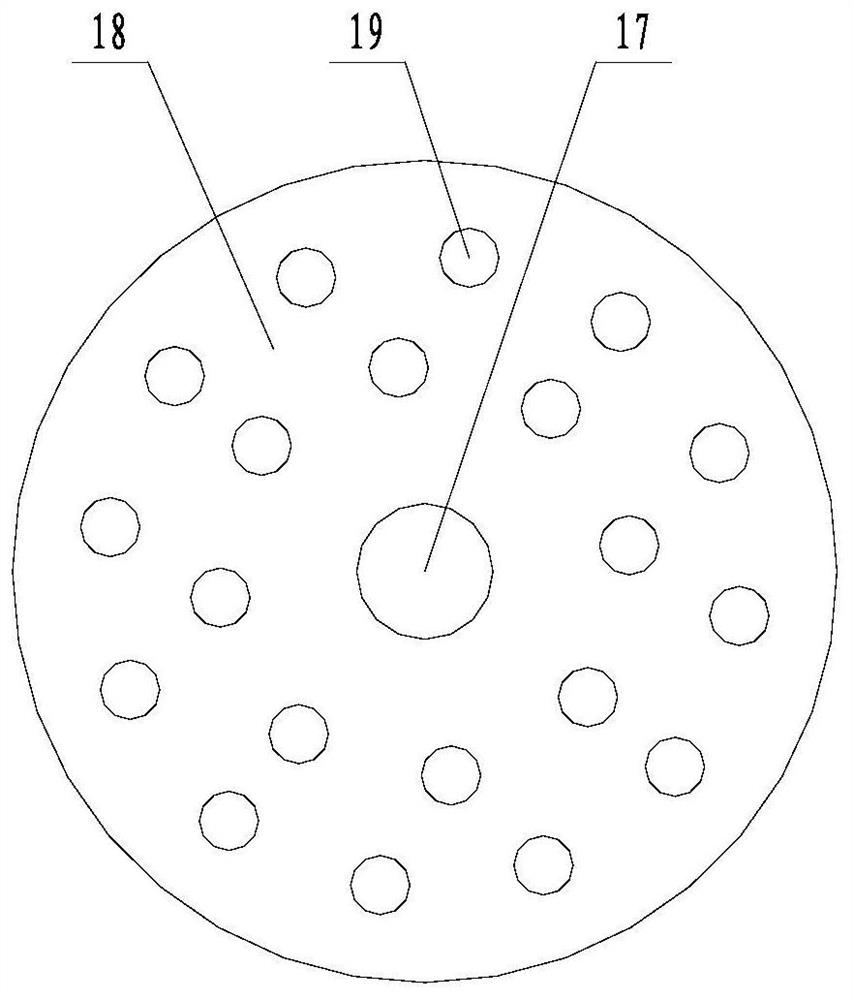

[0026] Such as Figure 1 to Figure 3 The shown container structure for long-term storage of staple grains includes a bin body 1, the bottom of which is fixedly connected to support legs 9, a funnel 10 is arranged directly above the bin body 1, and a partition 11 is arranged on the bottom surface of the funnel 10; The driving device 17 is fixed on the dividing plate 11, the driving end of the driving device 17 faces upward and is fixedly connected to the rotating disk 18, and the rotating disk 18 is provided with a plurality of evenly distributed first through holes 19, and the driving device 17 is used to drive the rotating disk 18 to rotate; Several second through-holes 12 are evenly distributed on the partition 11, and the bottom ends of each second through-holes 12 are connected to tubular passages 13, and the bottom ends of all passages 13 are located at the top of the warehouse body 1; Both the upper and lower surfaces are provided with a third through hole 2, the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com