Force transfer device for use with a valve train and method of manufacture

A technology of valve mechanism and force, applied in the direction of valve device, valve driving device, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

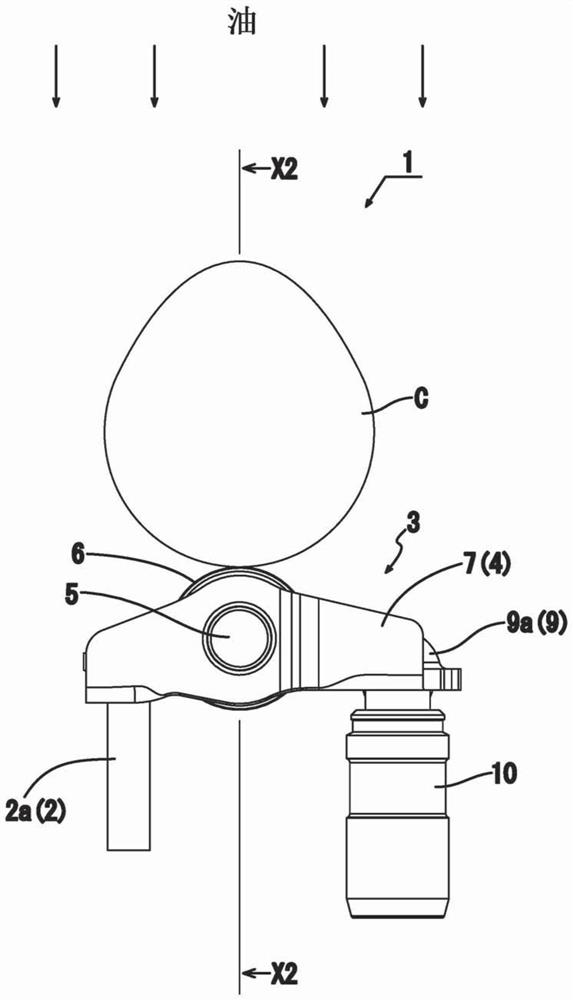

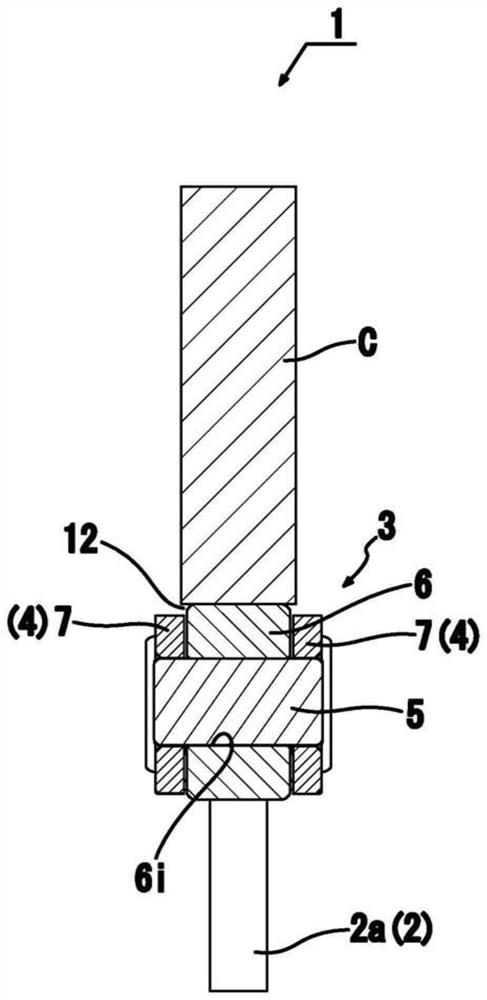

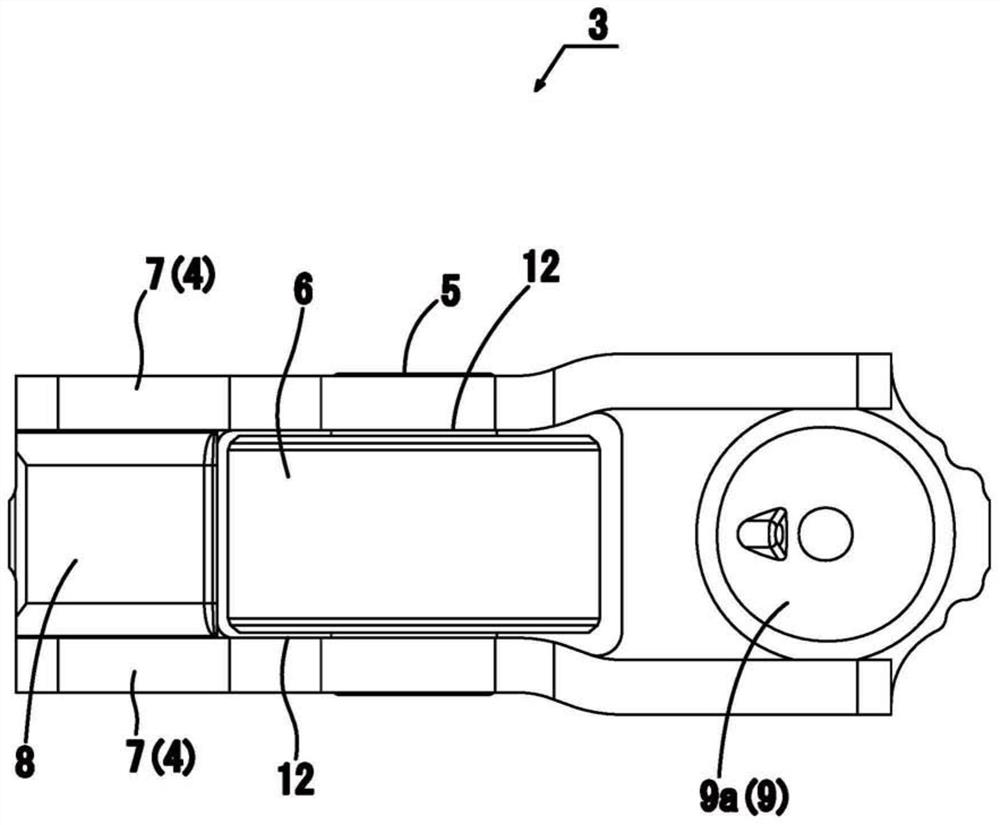

[0034]Hereinafter, examples of the present disclosure are explained in detail based on the accompanying drawings. refer to Figure 1 to Figure 9 Let's explain the first example of the present disclosure. In order to achieve the first purpose disclosed above, refer to Figure 1 to Figure 3 , a rocker arm structure for use with a valve train of an engine includes: an arm (4) for transmitting an action on the valve (2) to the action transmitting end of the arm (this end is called the action transmitting end) ) to open / close the force of the valve (2). The other end of the support shaft (5) towards the arm (4) protrudes laterally from the arm (4) at a position offset relative to said one end. A ring roller (6) is rotatably mounted on the outer periphery of the support shaft (5). The roller is rotated by the cam force applied to its outer circumference by the cam (C) to transmit the cam force to the support shaft (5) so as to transmit the cam force to the action transmitting en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com