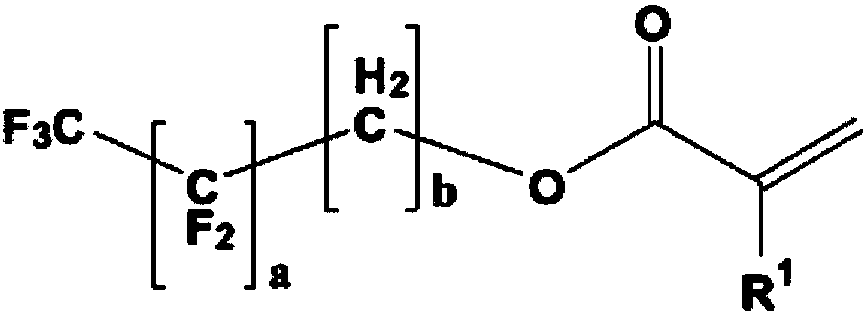

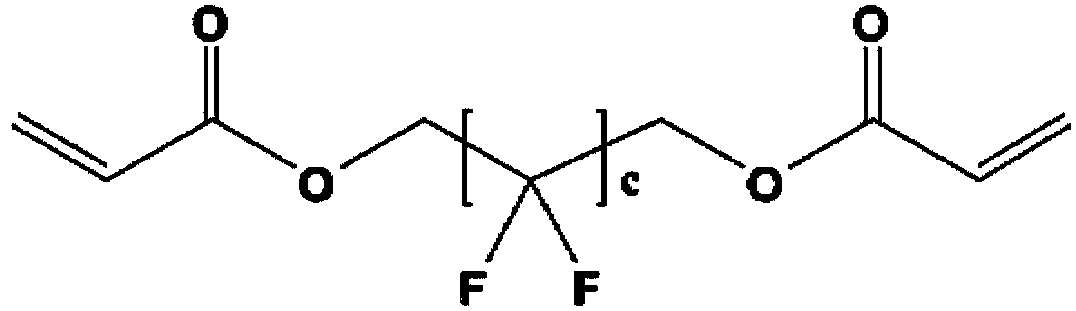

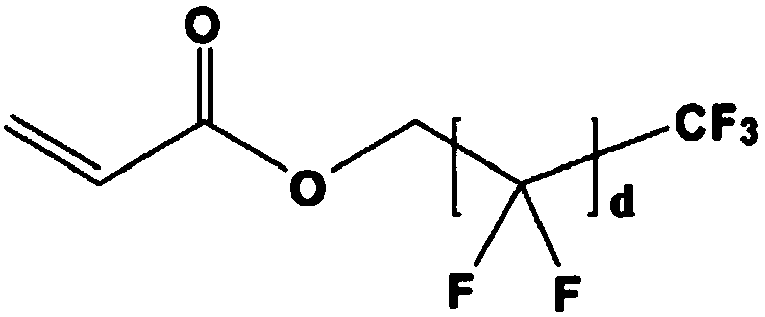

Photocurable coating composition, low-refraction layer, and anti-reflection film

A low-refractive index layer and coating composition technology, applied in the field of rights and interests, can solve the problems of weak interlayer adhesion, reduced interface adhesion, and unsatisfactory performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0141] Preparation Example 1: Preparation of Hard Coating Film (HD1)

[0142] (1) Preparation of hard coating film (HD1)

[0143] A salt-type antistatic hard coat liquid manufactured by KYOEISHA Corporation (solid content: 50% by weight, product name: LJD-1000) was coated on a triacetylcellulose film with a #10 Meyer bar and dried at 90° C. for 1 minute, Then at 150mJ / cm 2 Ultraviolet rays were irradiated to prepare a hard coat film (HD1) having a thickness of 5 μm.

preparation Embodiment 2

[0144] Preparation Example 2: Preparation of Hard Coating Film (HD2)

[0145] 30 g of pentaerythritol triacrylate, 2.5 g of high molecular weight copolymer (BEAMSET 371, Arakawa, epoxy acrylate, molecular weight 40,000), 20 g of methyl ethyl ketone and 0.5 g of leveling agent (Tego Wet 270) After uniform mixing, 2 g of acrylic-styrene copolymer resin fine particles (volume average particle diameter: 2 μm, manufacturing company: Sekisui Plastics) having a refractive index of 1.525 were added to prepare a hard coat composition. The resulting hardcoat composition was coated on a triacetylcellulose film with a #10 Meyer bar and dried at 90°C for 1 minute. at 150mJ / cm 2 The dried product was irradiated with ultraviolet rays to prepare a hard coat film having a thickness of 5 μm.

[0146]

[0147] (1) Preparation of Photocurable Coating Composition for Forming Low Refractive Index Layer

[0148] The components in Table 1 and Table 2 below were mixed and diluted in a solvent MIB...

experiment example

[0162]

[0163] The following experiments were performed on the antireflection films obtained in Examples and Comparative Examples.

[0164] 1. Measurement of average reflectance

[0165] Darken one side of the anti-reflection film prepared above, and then measure at 480 nm using SolidSpec 3700 (SHIMADZU) in measurement mode when HD1 is used as the hard coat layer and in 100% T mode when HD2 is used as the hard coat layer Average reflectance in the wavelength region to 780nm.

[0166] 2. Measurement of scratch resistance

[0167] The surfaces of the antireflection films obtained in Examples and Comparative Examples were rubbed while steel wool was loaded and rubbed back and forth 10 times at a reciprocating rate of 27 times per minute. The maximum load at which scratches of 1 cm or less were observed with the naked eye was measured.

[0168] 3. Evaluation of antifouling performance

[0169] On the surfaces of the antireflection films obtained in Examples and Comparative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com