Revolution and rotation combined type herbarium dryer

A plant specimen and dryer technology, which is applied to drying chambers/containers, non-progressive dryers, drying solid materials, etc. Efficient work, simplified production, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

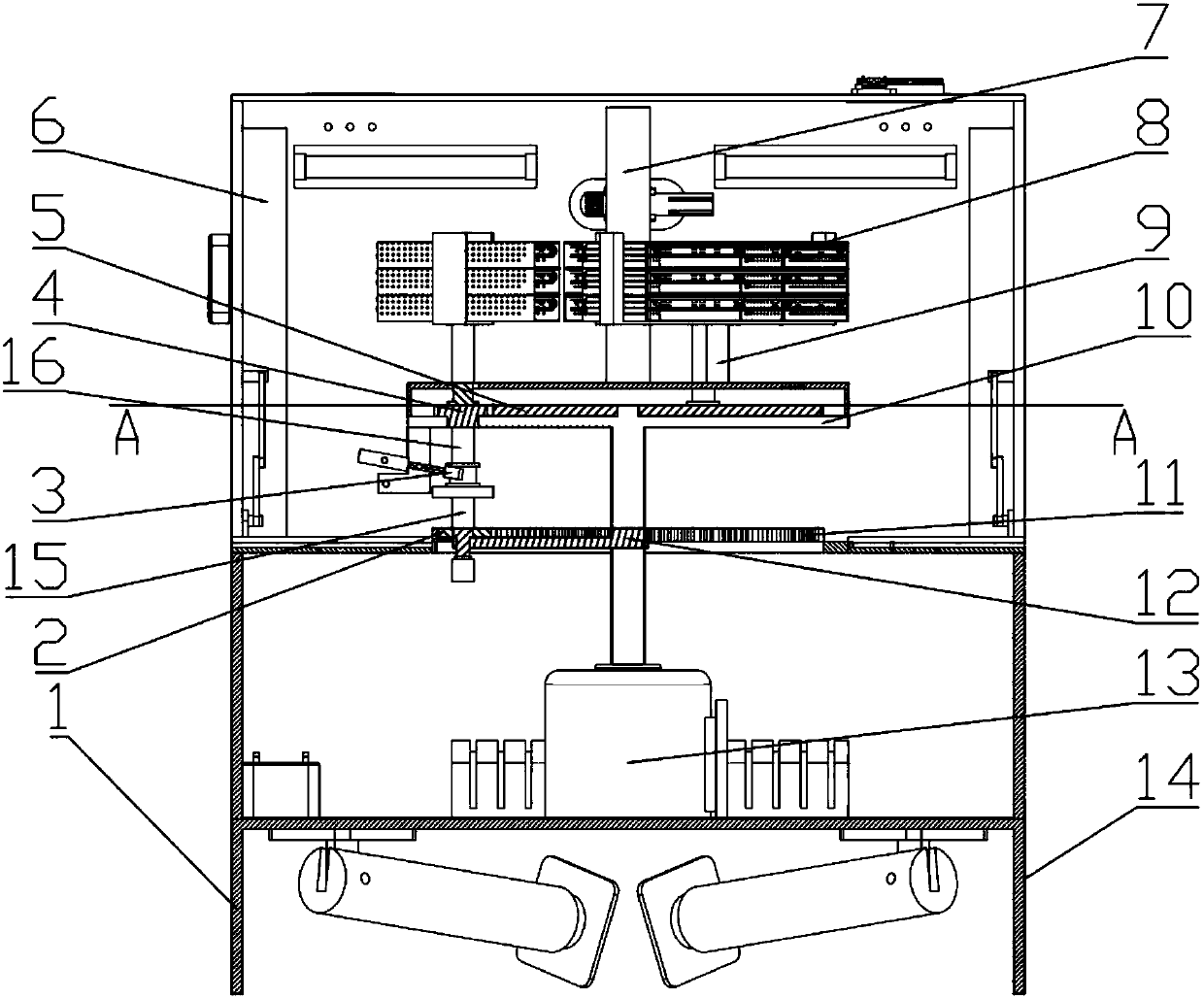

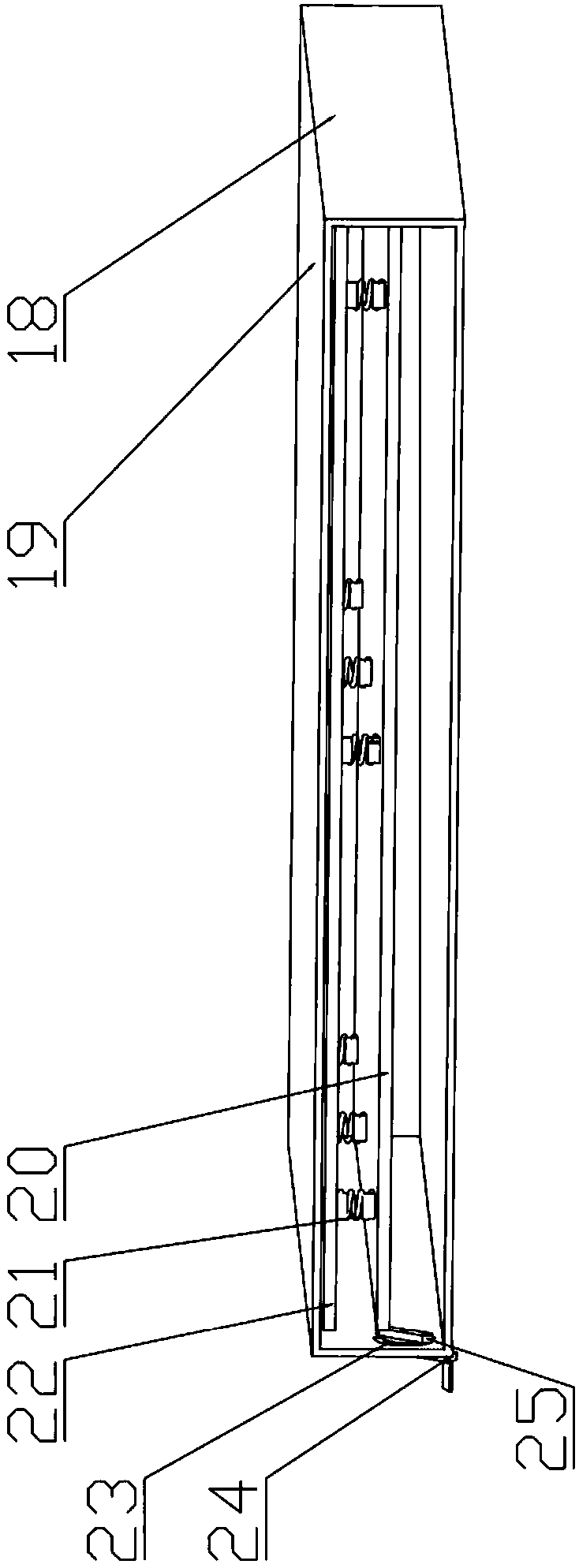

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A combined revolution and rotation type plant specimen dryer, a motor 13 is installed in the lower part of the cavity of the box body 1, and a heating plate 6 and a heating rod 7 are respectively installed on the inner wall surface and the center of the upper part of the cavity of the box body 1. The power generation board 14 is fitted on the outer lower side wall surface of the box body 1, and the inner ring gear 11 is fixed in the cavity of the box body 1 at the outer part of the motor shaft circumference of the motor 13, and the revolution drive is fixed on the motor shaft of the motor 13. The arm 12, the rotation drive shaft 15 is axially and radially positioned and circumferentially rotatable fitted on the outer end of the revolution drive arm 12, the rotation drive gear 2 is fixed on the rotation drive shaft 15, the rotation drive gear 2 It is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com