Error-assembling-proofing structure for die

A mold and positioning structure technology, which is applied in the field of mold assembly error-proof structure, can solve the problems of mold crushing, waste of cost, and parts misalignment, etc., and achieve the effect of high-quality mold manufacturing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific implementations are now described in detail.

[0013] Aiming at the error-proofing problem of various plastic molding products, a precision injection mold with an excellent fool-proof positioning structure is designed to improve product quality, improve yield, and save costs.

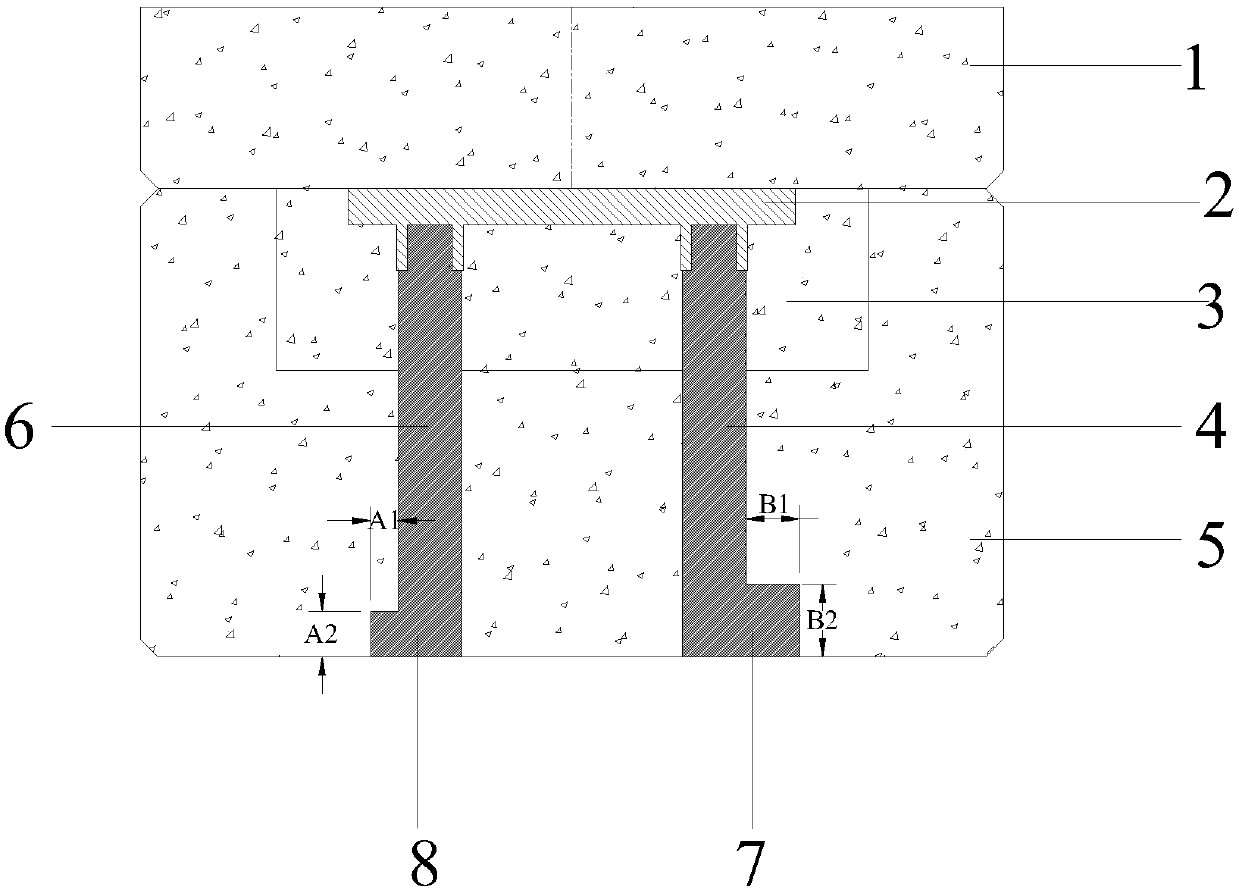

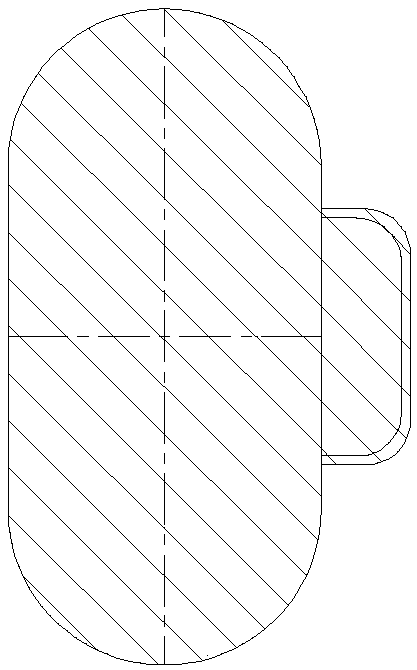

[0014] Such as figure 1 As shown, the structure for error-proofing mold assembly includes a fixed mold blank 1, a movable mold blank 5, and a movable mold core 3. The movable mold core 3 is installed in the movable mold blank 5, and the movable mold core 3 is provided on both sides of it. And the left and right insert holes of the movable mold blank 5, the bottom end of the left insert hole is provided with a left foolproof positioning structure 8, and the bottom end of the right insert hole is extended with a right Foolproof positioning structure 7, such as figure 2 Shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com