Green fresh-keeping sweet potato storage method

A sweet potato and green technology, applied in the field of sweet potato storage, can solve the problems of inedible, waste, and shriveled people or livestock, and achieve the effects of promoting wound healing, improving storage resistance, and reducing spoilage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of green fresh-keeping sweet potato storage method comprises the steps:

[0031] S01. In the sweet potato storage room, use mixed forage to smoke for 70 minutes. After the smoking is completed, spray potassium permanganate solution with a concentration of 0.1mol / L on the side wall, floor and top of the storage room. After spraying, close the sweet potato storage room. room for 110 minutes.

[0032] S02. After the sweet potato storage room is processed in step S01, technicians can coat the surrounding wall and the ground of the sweet potato storage room with photocatalyst, and turn on the light to continue to illuminate for 24 hours. At this time, the pretreatment of the sweet potato storage room is completed.

[0033] S03. Put the sweet potatoes with mud in plastic baskets, and the plastic baskets filled with sweet potatoes can be stacked together, thereby reducing the collision between sweet potatoes, reducing the space occupied by sweet potatoes, and increasing...

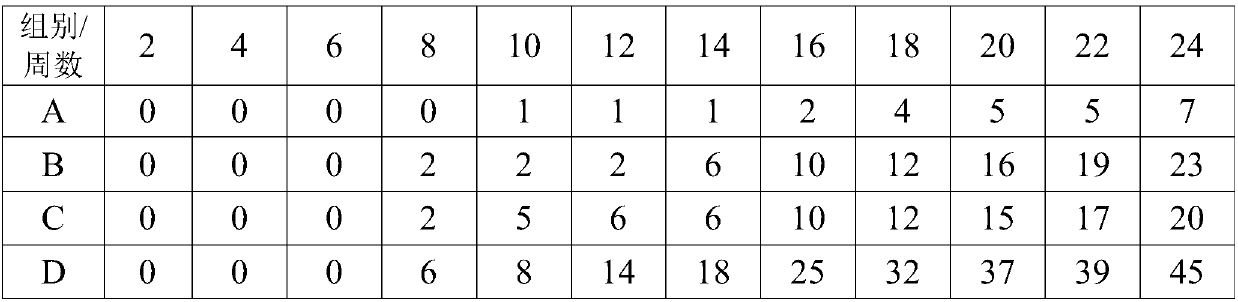

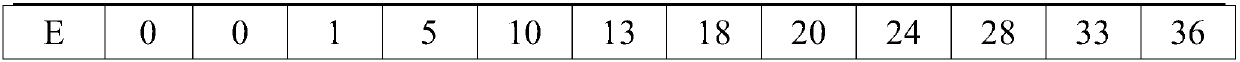

Embodiment 2

[0038] Example 2 (Smoking Sweet Potato Storage Room Without Mixed Materials)

[0039] This embodiment is repeated in the same steps as in embodiment 1, but the sweet potato storage room is not smoked in step S01 by using mixed forage.

Embodiment 3

[0040] Embodiment 3 (sweet potato storage room does not adopt photocatalyst to carry out sterilizing treatment)

[0041] Repeat the present embodiment by the same steps as in embodiment 1, but do not use the photocatalyst to smear the inner peripheral wall and the ground of the sweet potato storage room in step S02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com