Magnetizing device and magnetizing method for six-sided magnetic levitation body

A magnetizing device and magnetic levitation technology, which is applied in the direction of magnetic objects, circuits, electrical components, etc., can solve problems such as the inability to realize the magnetization of six-sided magnetic levitation bodies, achieve simple and practical magnetization methods, improve the degree of mechanical automation, and improve the charging efficiency. The effect of magnetic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

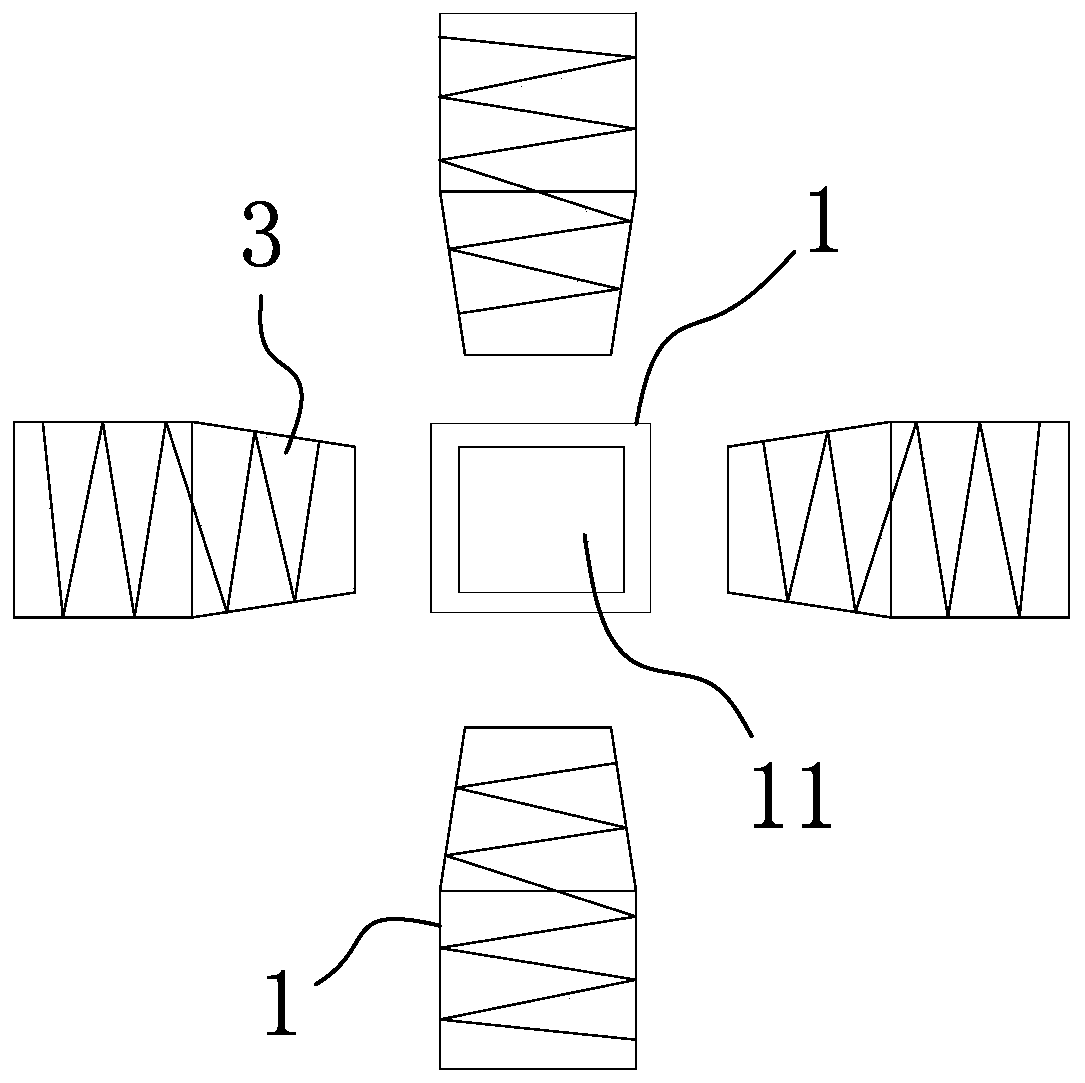

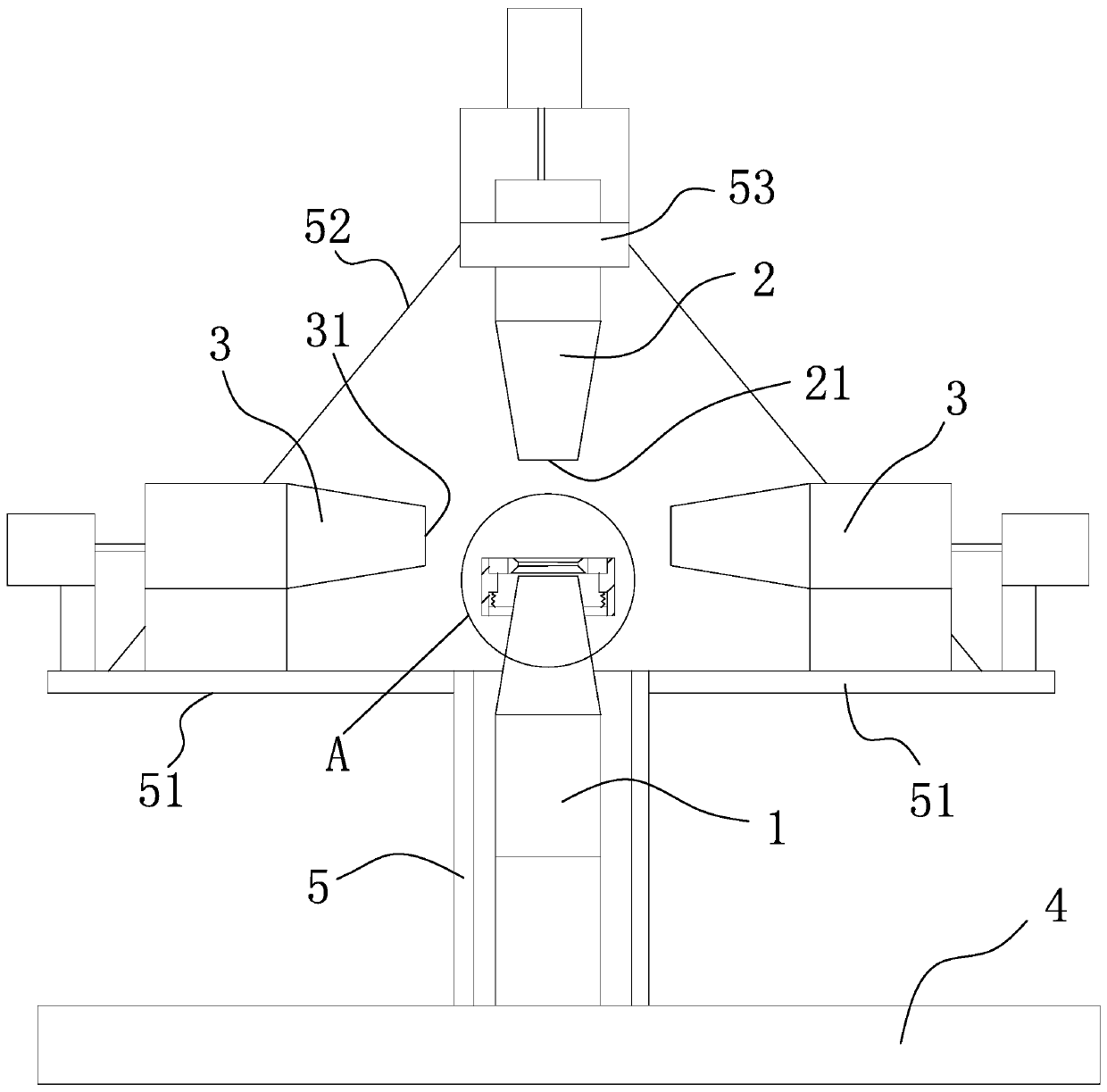

[0051] Such as figure 1 As shown, the magnetizing device of the six-sided magnetic levitation body includes a vertically arranged lower magnetizing head 1 and an upper magnetizing head 2 directly above the lower magnetizing head 1, and the device also includes four circumferentially distributed and horizontally arranged side faces Charging head 3,

[0052] The above-mentioned lower magnetic charging head 1 , upper magnetic charging head 2 and side surface magnetic charging head 3 are respectively arranged on the frame.

[0053] Such as image 3 As shown, further, the lower charging head 1 is fixed on the frame 4 .

[0054] The frame 4 is provided with a second lift drive mechanism that drives the upper magnetic charging head 2 to move up and down in the vertical direction.

[0055]Each side magnetic charging head 3 is respectively connected with a horizontal driving mechanism, and said horizontal driving mechanism is respectively connected on the frame 4 .

[0056] The lat...

Embodiment 2

[0073] The structure and principle of this embodiment are basically the same as that of Embodiment 1, so it will not be described in detail here, but the difference is that: the frame 4 is provided with a first mechanism that drives the lower magnetic charging head 1 to lift in the vertical direction. Lifting drive mechanism.

Embodiment 3

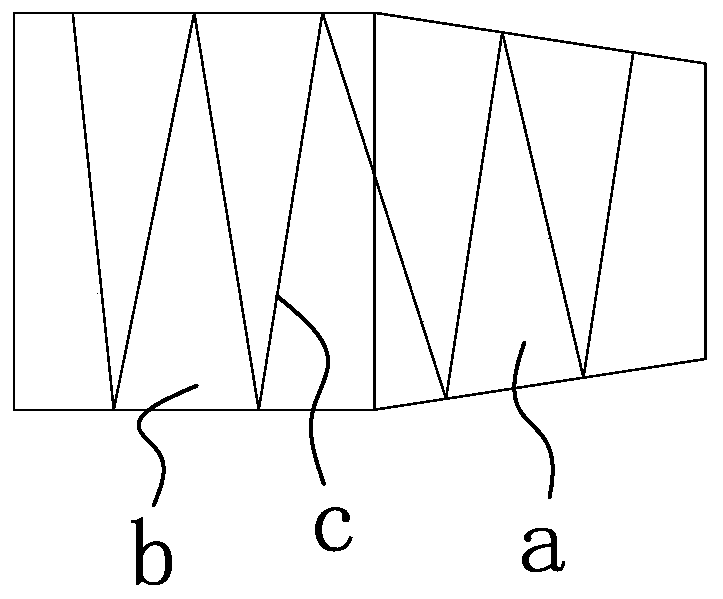

[0075] The structure and principle of this embodiment are basically the same as those of the first embodiment, so they will not be repeated here. The difference lies in the fact that an electrified coil c is sheathed on the outside of the tapered section a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com