Technical scheme for implementing nontraditional VSM value flow analysis

A technical solution and value stream technology, applied in the field of non-traditional VSM value stream analysis, it can solve the problems of loose scheduling plan linkage, low reusability, and scheduling capacity information not necessarily updated in time, so as to achieve clear organization and simple methods. , the effect of facilitating the efficient update and maintenance of process data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A technical solution for realizing non-traditional VSM value stream analysis includes the following steps:

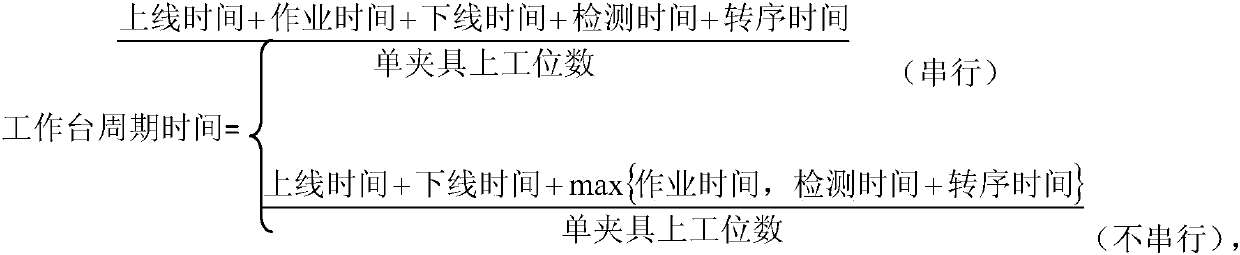

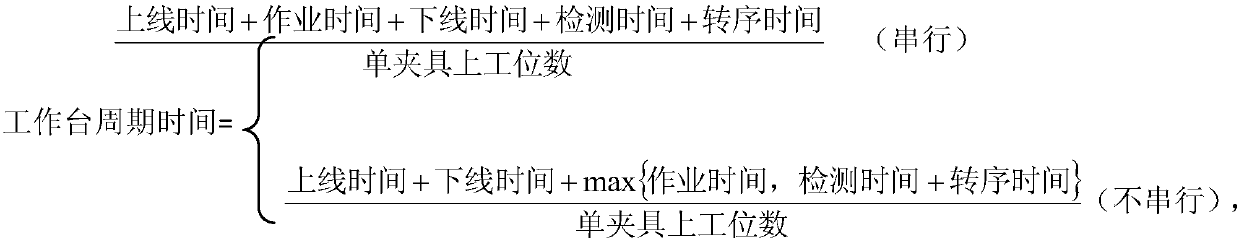

[0034] Step 1. Collect and regulate the working time parameters of each workbench: According to ergonomics or motion analysis, the general time parameters should be closely related to the various action steps of the workbench. The more complex the actions, the more complex the time parameters, and each The action steps are summarized as line change preparation, on-line, operation, off-line, inspection, and shift sequence. Data closely related to time parameters are collected, including the number of working positions of a single fixture, the number of effective fixtures, and whether two adjacent operations are completely connected. Reliability coefficient of row and workbench;

[0035] Step 2. Collect and organize the resource and quality data of each workbench: The resources and quality data are very complex, and they are organized into the number of personnel, facil...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is:

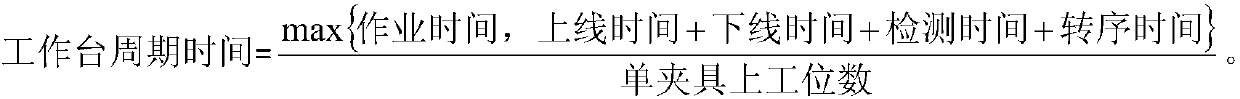

[0050] The number of effective fixtures is 2, and the calculation formula of the workbench cycle time is:

[0051]

[0052] The invention uses sub-processes as the unit, divide and conquer, and finally re-synthesize, which is convenient, fast and clear; no special symbols, using data to reflect, high drawing efficiency; simple method, can be quickly mastered; normal compilation of VSM, keeping it in an updated state at any time , Not only for continuous improvement of the enterprise, but also for daily operation guidance; through the improvement points of the VSM, it is quickly prompted to organically bind the current VSM and the future VSM, which can quickly locate the potential improvement points without drawing the future VSM, which greatly Improved efficiency; and because of the unique method of the VSM of the present invention, only partial data can be updated during the improvement process and the entire VSM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com