A device for supporting optical elements

A technology for optical components and placing tables, which is applied in the direction of optical components, optics, installation, etc., can solve problems affecting the surface shape of optical components, reduce assembly and fixing stress, avoid surface shape being affected, and eliminate radial forces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

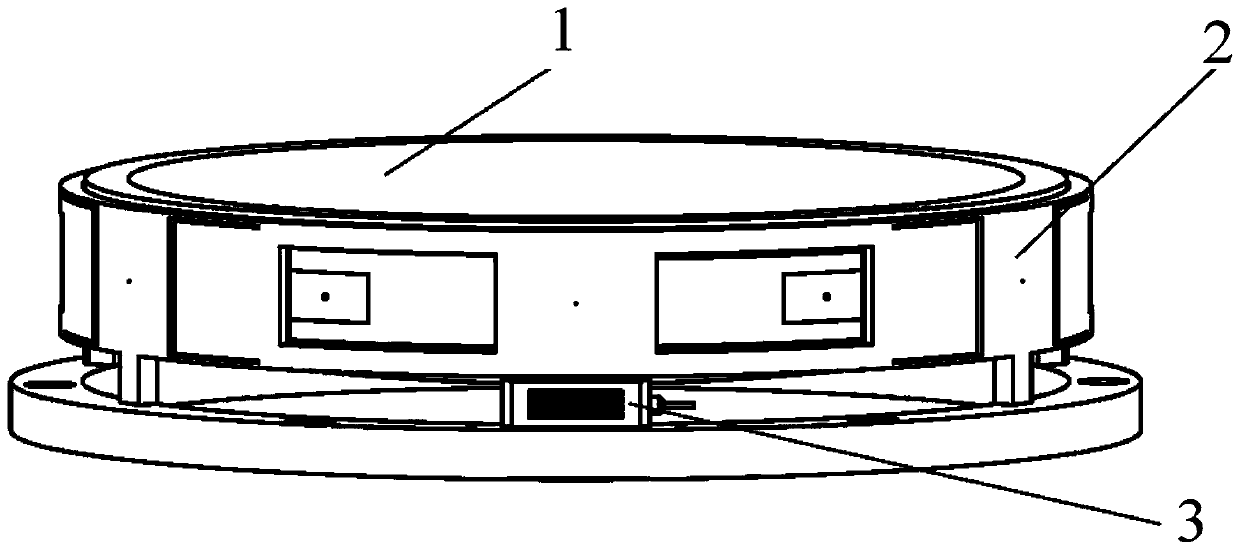

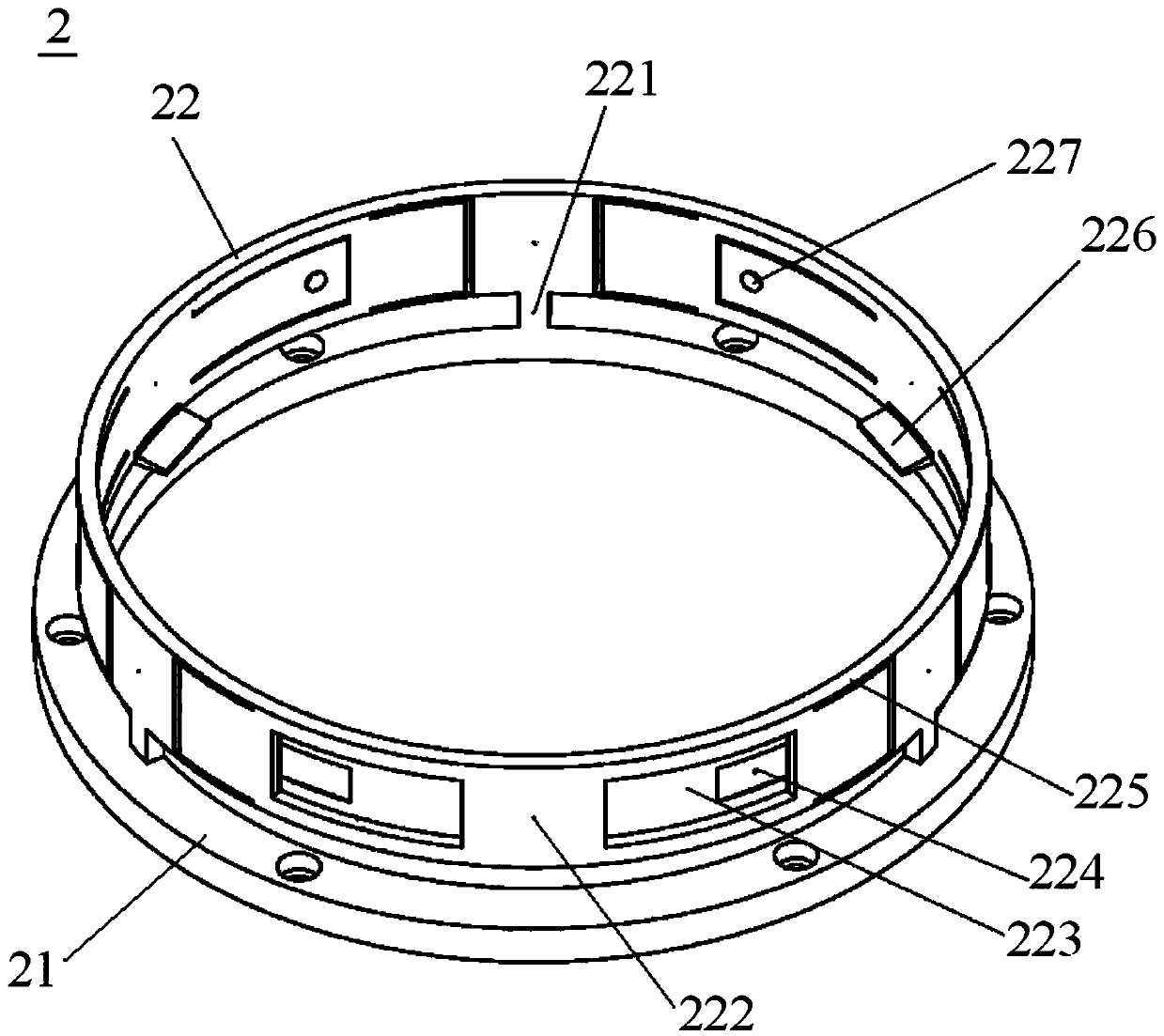

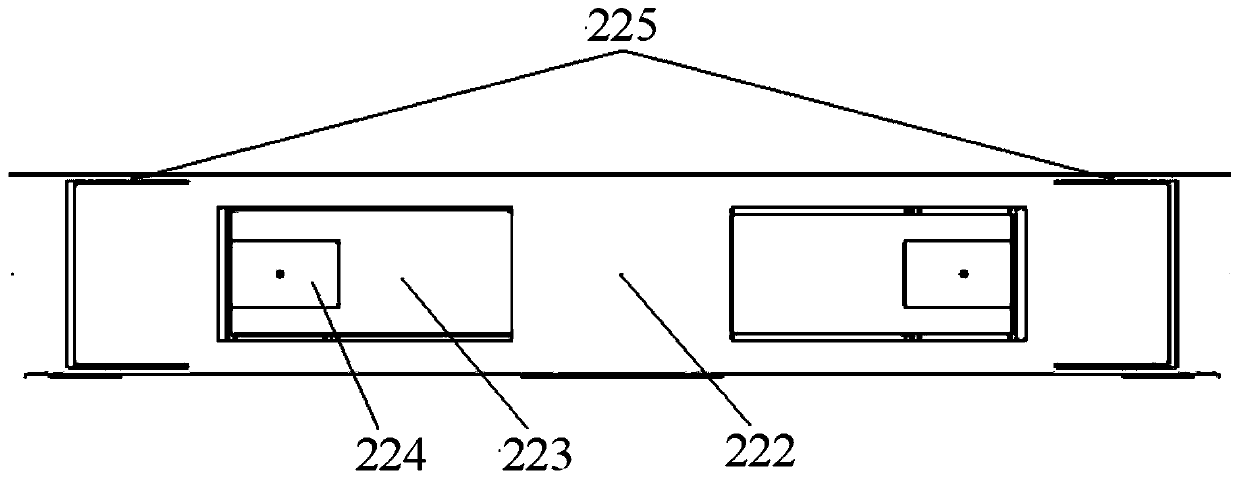

[0027] see Figure 1 ~ Figure 3 , figure 1 It is a diagram of the use state of a device for supporting optical elements provided by Embodiment 1 of the present invention; figure 2 yes figure 1 Schematic diagram of middleware 2; image 3 yes figure 1 Partial schematic diagram of middleware 2.

[0028] The device for supporting optical elements provided by Embodiment 1 includes a support frame 2, which includes a horizontally arranged base 21 and an annular body 22 above the base 21, such as figure 2 As shown, the axis of the ring body 22 is in the vertical direction, and the lower end surface of the ring body 22 has a plurality of legs 221 evenly distributed around the axis, the legs 221 are fixedly connected to the base 21, and the ring body 22 is located at the front of the legs 221. The part above is called the fixed segment (unmarked among the figures), and the part of the annular body 22 that is positioned between two adjacent fixed segments is called the floating s...

Embodiment 2

[0036] Such as figure 2 As shown, in the first embodiment, the upper surface of the placing platform 226 is an inclined surface, and one end of the inclined surface close to the center of the annular body 22 is lower than the other end. The difference between the second embodiment and the first embodiment is that the placing platform 226 has different shapes. In the second embodiment, the upper surface of the placing platform 226 is a horizontal plane.

[0037] In each of the above embodiments, the number of legs 221 may be 3-5. In order to be able to adjust the posture of the optical element 1, a plurality of linear actuators 3 equal in number to the legs 221 can also be provided, and the plurality of linear actuators 3 are evenly distributed around the axis of the annular body 22, and are located in the center of the floating section 222. Directly below. In addition, for the convenience of control, a controller can be provided, and a plurality of linear actuators 3 are el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com