A grating ruler reliability test bench and a reliability test method based on load spectrum

A test method and technology of grating scale, applied in the direction of using optical devices, instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

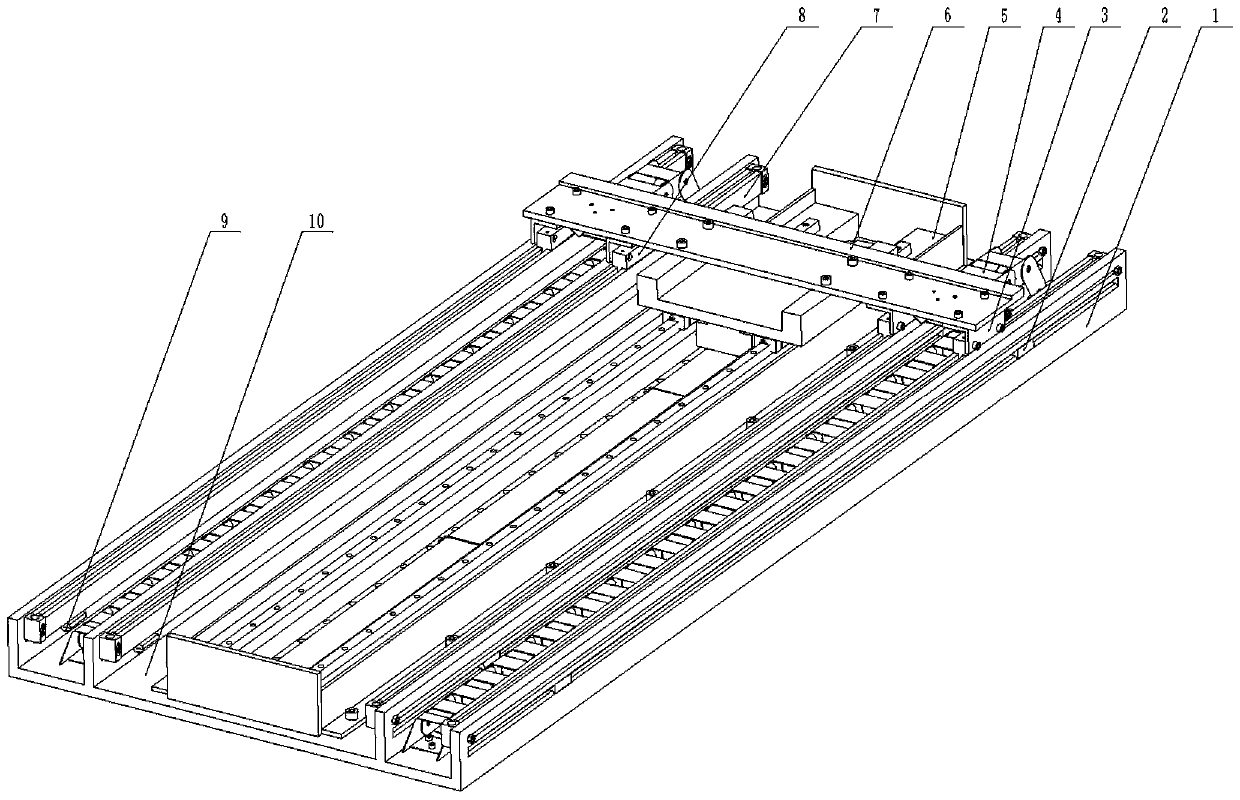

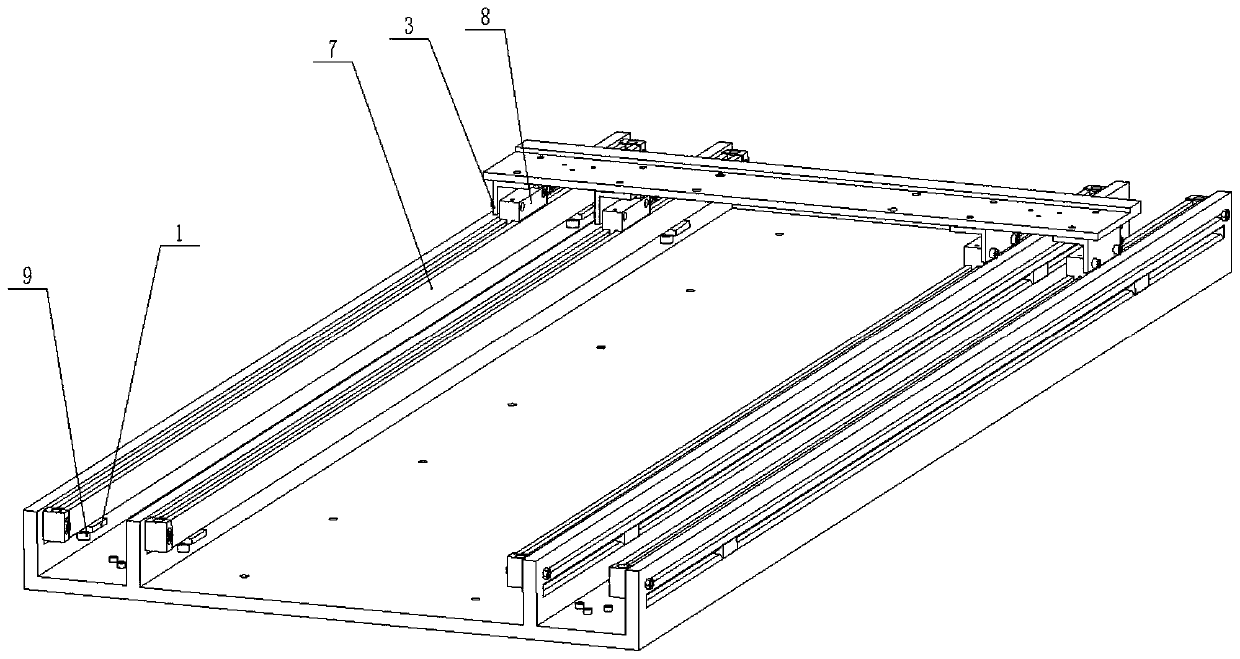

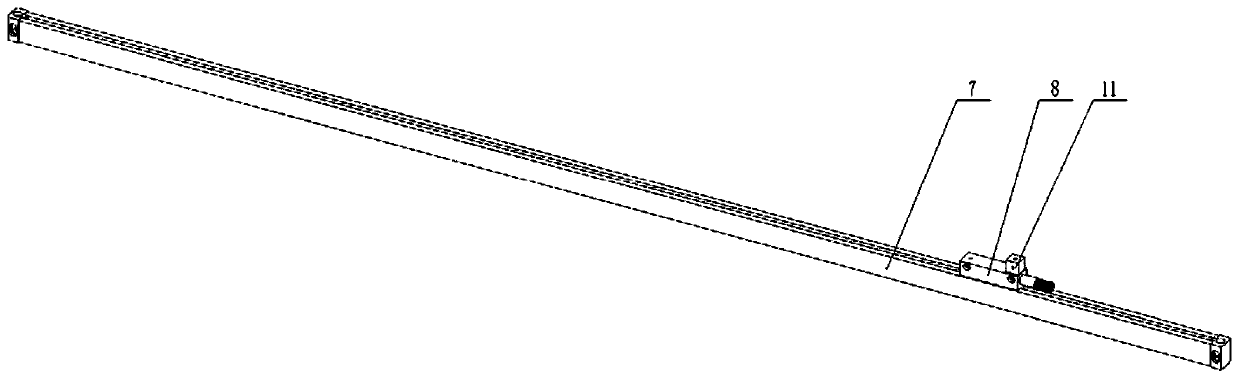

[0053] The structure of embodiment 1 grating ruler reliability test bench is

[0054] The bottom plate 501 of the linear motor 5 is fixed on the bottom plate 10 by bolts, the slide plate 6 is fixed on the linear motor slider 506 by bolts, so as to move synchronously with the linear motor mover 505, and the grating ruler reading head 8 is installed by the bolts and the grating ruler reading head The plate 3 is fixed, and the grating ruler reading head installation plate 3 is fixed on the slide plate 6 by bolts, so that the grating ruler reading head 8 and the linear motor mover 505 move synchronously, and the grating ruler main ruler installation plate 1 is fixed on the bottom plate 10 by bolts, so that The main scale 7 of the grating scale is fixed, so that the reading head 8 of the grating scale realizes the relative movement with the main scale 7 of the grating scale under the drive of the linear motor mover 505. Synchronous movement, the lower part of the drag chain 4 is fi...

Embodiment 2

[0063] Embodiment 2 The reliability test method based on load spectrum of the present invention

[0064] It is carried out on the basis of the grating ruler reliability test bench. During the test, the grating ruler reliability test bench can be installed with multiple grating rulers at the same time for the reliability test of the velocity spectrum and acceleration spectrum. The grating ruler reliability test bench described in the present invention can not only simulate the speed and acceleration loads that the grating ruler bears under actual working conditions, but also conduct reliability tests under normal stress, and at the same time, perform reliability tests higher than normal stress levels. test; including:

[0065] 1. Reliability test method based on velocity spectrum

[0066] During the actual operation of the grating scale, the main load it bears is the velocity load. Therefore, the reliability test of the grating scale based on the velocity spectrum can effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com