High-performance sealing shaft sleeve for spiral centrifugal pump

A technology for screw centrifugal pumps and sealed shaft sleeves, which is applied in the direction of pumps, pump components, and non-variable pumps, etc. To avoid problems such as spillage, to achieve the effect of ensuring efficient and stable operation, axial stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

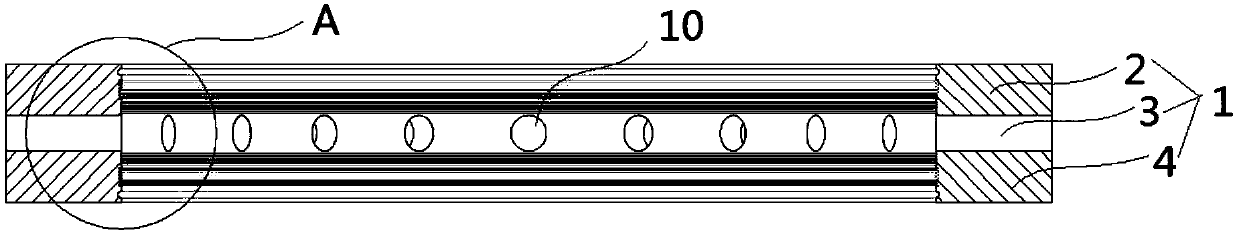

[0022] A high-performance sealing bushing for a screw centrifugal pump, comprising an inner bushing 11 and an outer bushing 12, characterized in that the inner bushing 11 is in a cylindrical shape, and the inner wall of the cylindrical shape is A plurality of sealing rings 1 are provided, and the plurality of sealing rings 1 are equally spaced and parallel and evenly distributed. The outer shaft sleeve 12 includes a sleeve 13 and a connecting plate 14, and the sleeve 13 and the connecting plate 14 are of an integrated structure. The casing 13 is in clearance fit with the inner shaft sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com