Running water slag remover

A slag remover and flowing water technology, which is used in water supply installations, water conservancy projects, waterway systems, etc., can solve problems such as blockage of drainage pipes, poor drainage, and no running water slag removal device, so as to ensure smooth drainage and maintain smooth drainage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

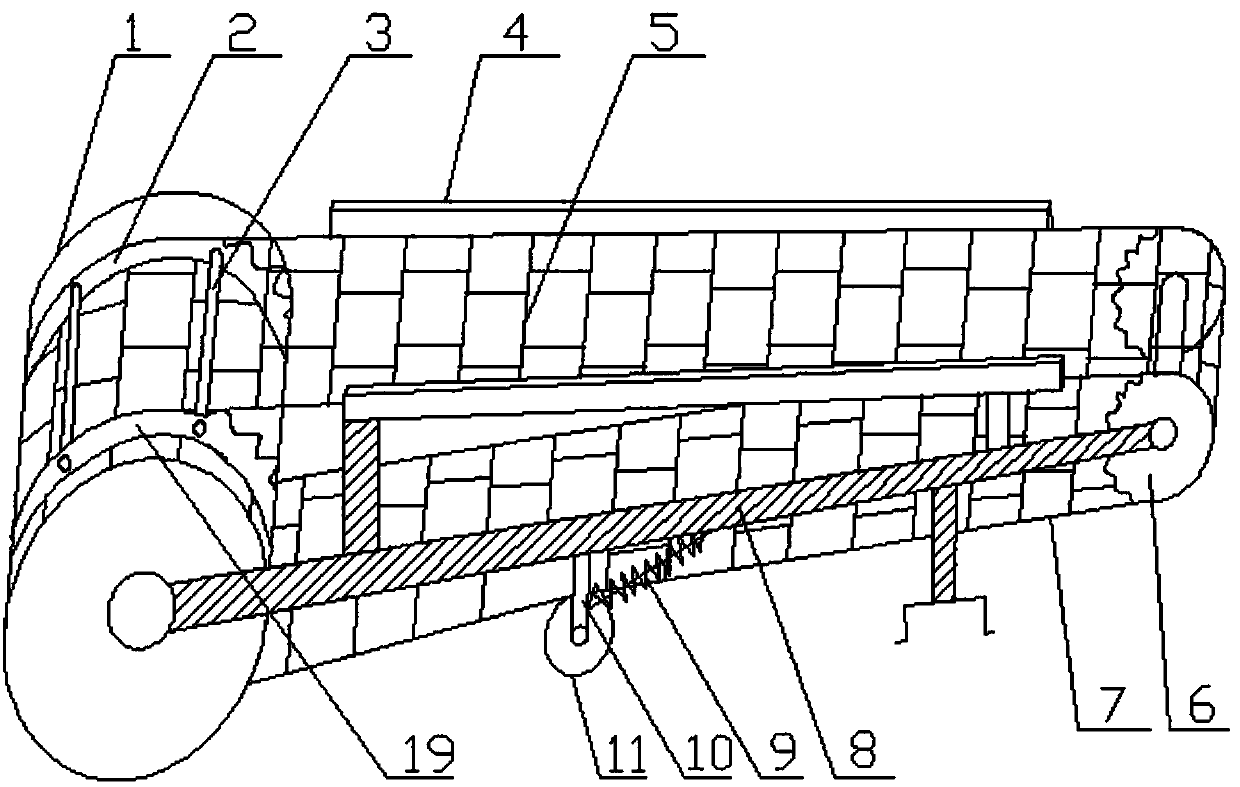

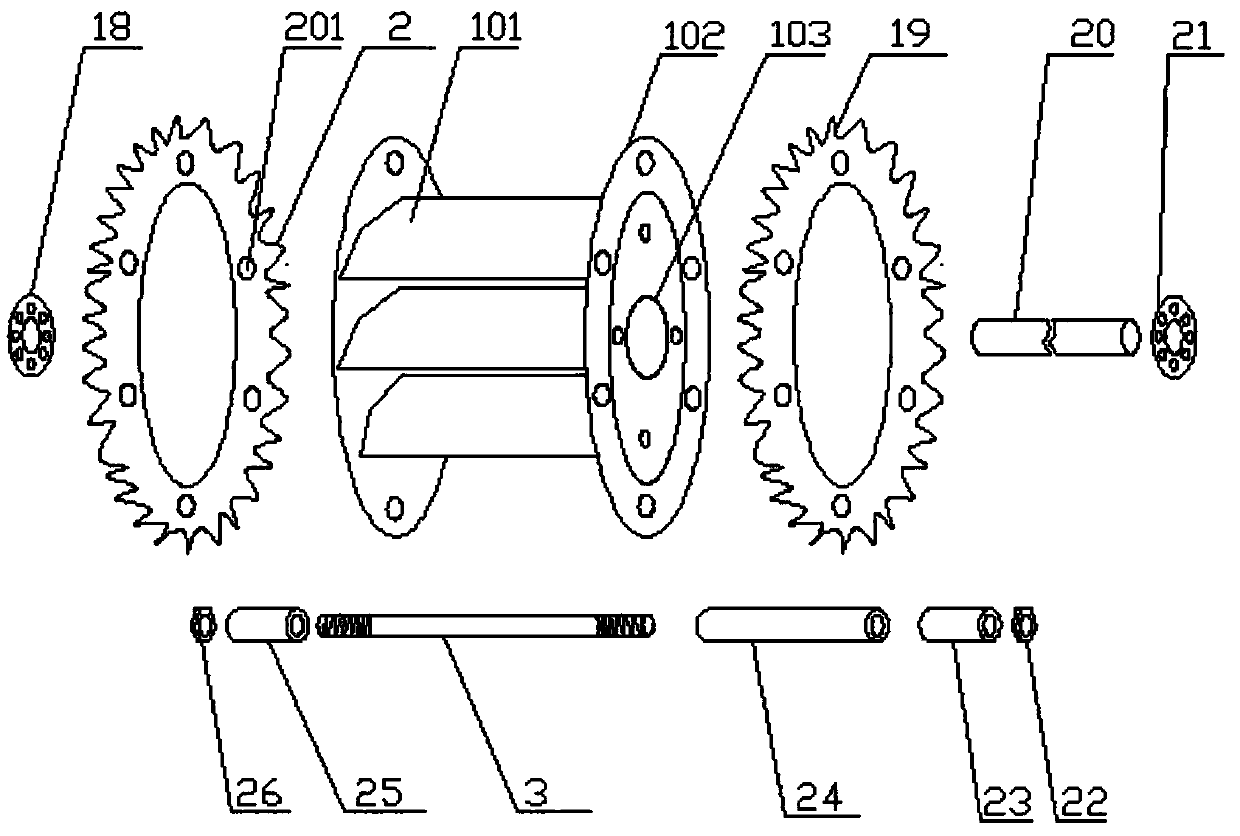

[0035] Such as figure 1 with figure 2 As shown, a flowing water slag remover includes a frame 8, a water wheel 1, a transmission device, and a crawler water grate 5. In the transmission device, two front gear rings are coaxially rotated, and each of the two front gear rings passes through one The transmission chain 7 is connected to a rear gear ring 6, two rear gear rings 6 are coaxially rotatably arranged on the frame 8, the crawler water grate 5 is connected between the two transmission chains 7, and the water wheel 1 is rotatably arranged on the frame 8. It is arranged coaxially with the two front gear rings, and the water wheel 1 drives the crawler water grate 5 to rotate through a transmission device. When water flows down from above the crawler water grate, the water passes through the grate hole on the crawler water grate, and the water passing through the grate hole of the crawler water grate is injected downwards into the water wheel, thereby driving the water wheel to...

Embodiment 2

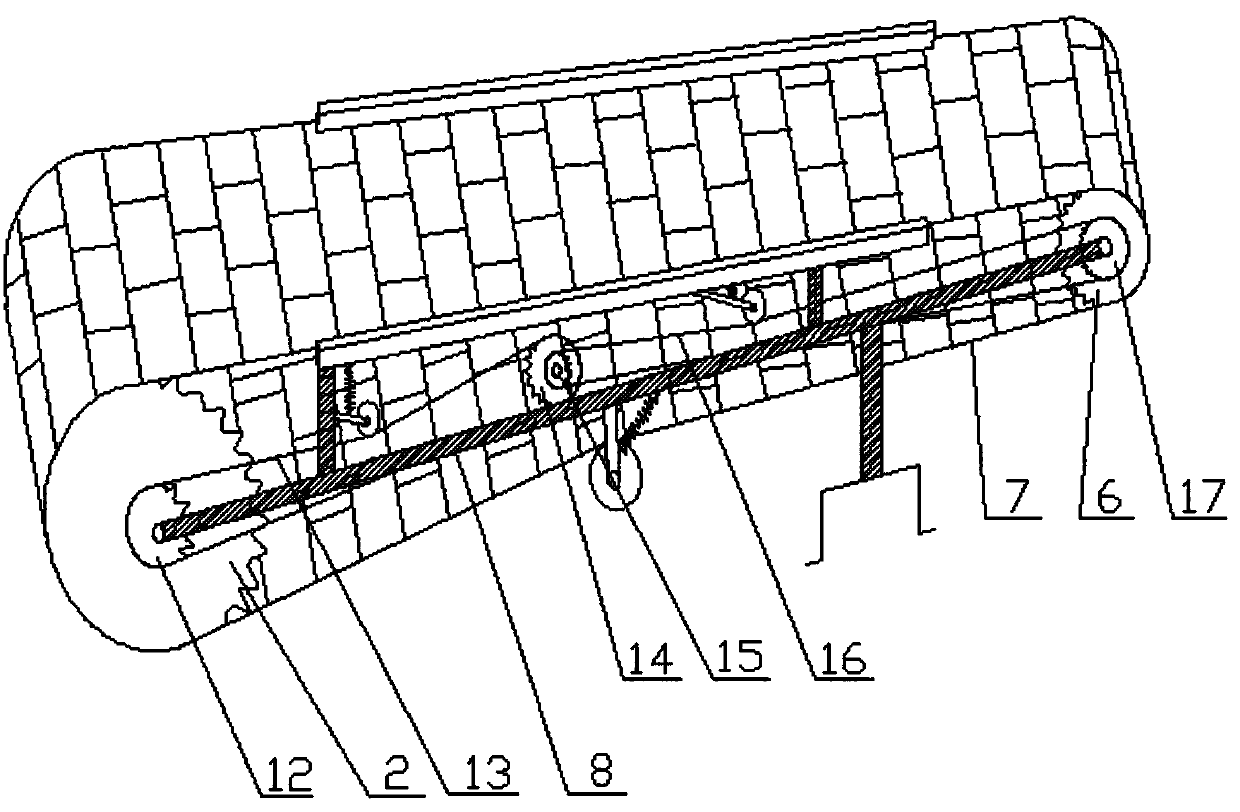

[0046] Such as image 3 with Figure 4 As shown, a flowing water slag remover includes a frame 8, a water wheel 1, a transmission device, and a crawler water grate 5. In the transmission device, two front gear rings are coaxially rotated, and each of the two front gear rings passes through one The transmission chain 7 is connected to a rear gear ring 6, two rear gear rings 6 are coaxially rotatably arranged on the frame 8, the crawler water grate 5 is connected between the two transmission chains 7, and the water wheel 1 is rotatably arranged on the frame 8. It is arranged coaxially with the two front gear rings, and the water wheel 1 drives the crawler water grate 5 to rotate through a transmission device. When water flows down from above the crawler water grate, the water passes through the grate hole on the crawler water grate, and the water passing through the grate hole of the crawler water grate is injected downwards into the water wheel, thereby driving the water wheel to...

Embodiment 3

[0054] A flowing water slag remover, comprising a frame 8, a water wheel 1, a transmission device and a crawler water grate 5. Two front gear rings are arranged coaxially in the transmission device, and each of the two front gear rings passes through a transmission chain 7 A rear gear ring 6 is connected, two rear gear rings 6 are coaxially rotatably arranged on the frame 8, the crawler water grate 5 is connected between the two transmission chains 7, and the water wheel 1 is rotatably arranged on the frame 8 and connected with the two The front gear ring is arranged coaxially, and the water wheel 1 drives the crawler water grate 5 to rotate through the transmission device. When running water flows down from the top of the crawler water grate, the running water passes through the grate hole on the crawler water grate, and the debris in the running water is transported by the crawler water grate to one end of the slag remover, thereby achieving the slag removal of the running wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com