Clothes processing device dehydration control method and clothes processing device

The technology of a clothes treatment device and a control method is applied in the field of clothes treatment device and dehydration control of clothes treatment device. Quality and effect of preventing abnormal conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

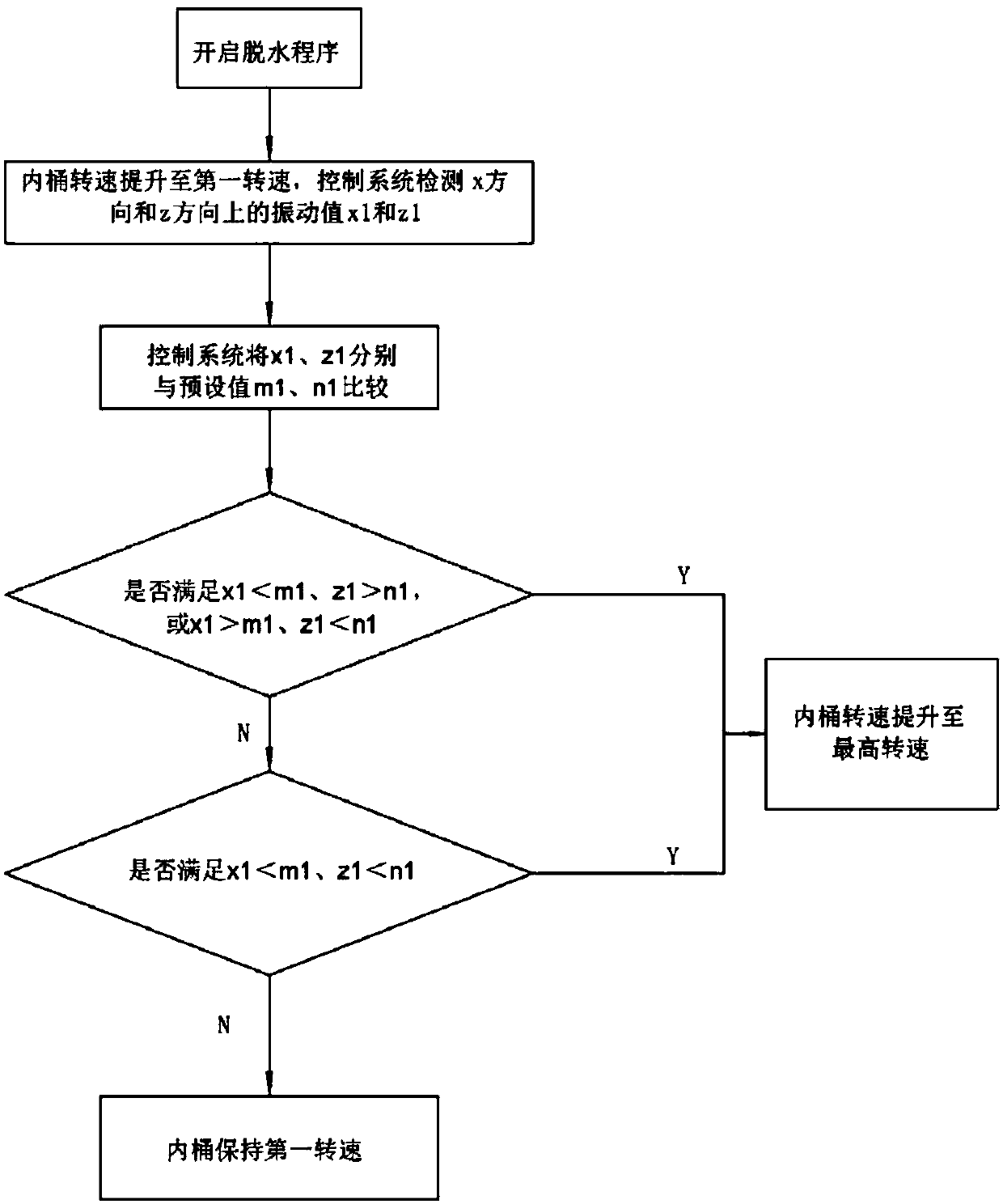

Embodiment 1

[0057] like figure 2 As shown, a method for controlling the dehydration of a clothes processing device in this embodiment is provided with a maximum rotation speed reached by the inner tub, and a first rotation speed during the rotation to the highest rotation speed, and the inner tub is detected at both the first rotation speed and the highest rotation speed. Vibration values in at least two directions; when the inner tub runs to the first rotational speed or the highest rotational speed, if the vibration value detected by the inner tub in one direction satisfies the preset value corresponding to the rotational speed, and the vibration value detected in the other direction If the preset value corresponding to the rotating speed is not satisfied, the inner barrel is controlled to run to another rotating speed, and the above process is repeated; during the above detection process, when the vibration values of the inner barrel in all directions are detected to meet the prese...

Embodiment 2

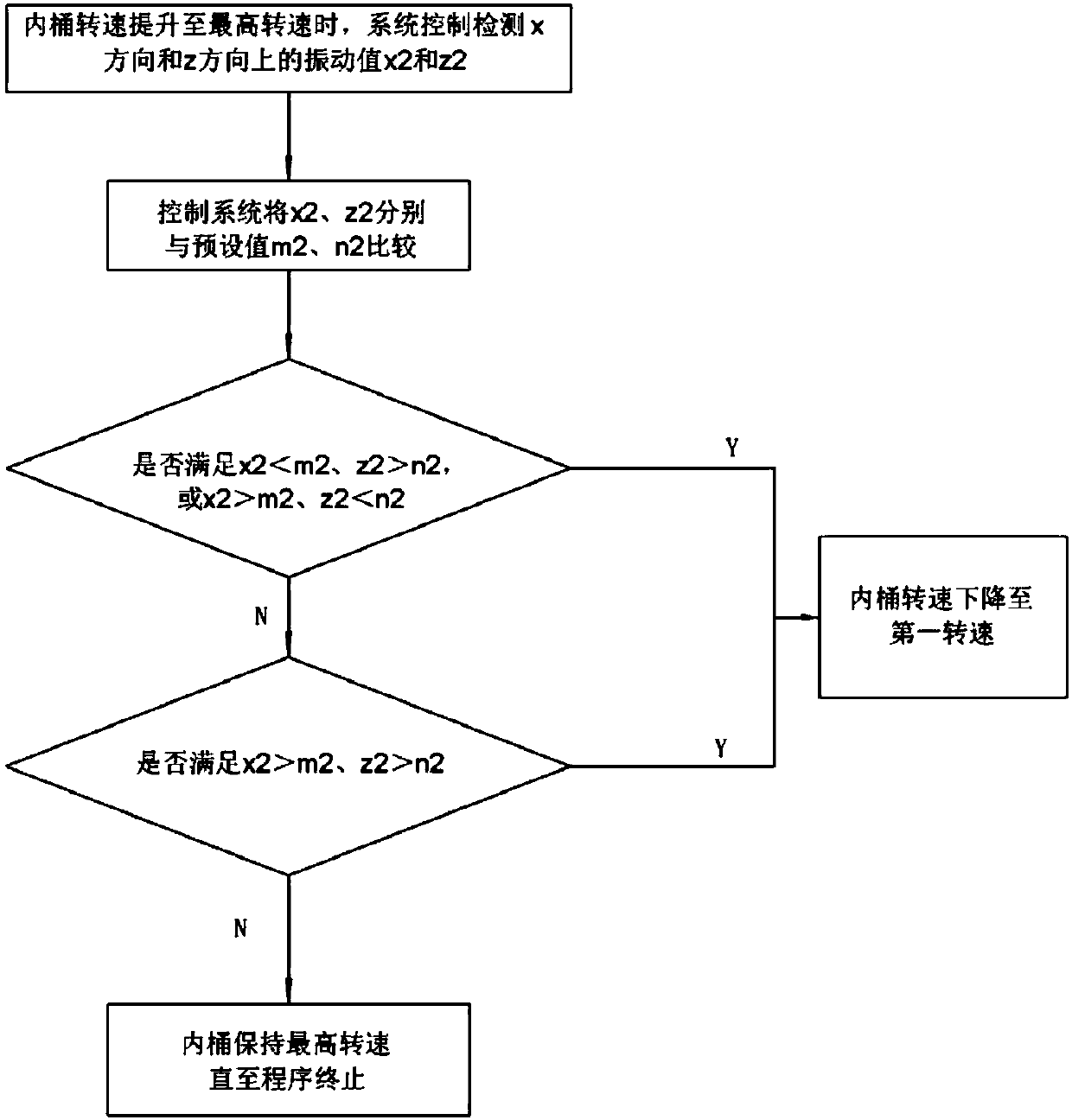

[0071] like figure 2 As shown, the difference between the dehydration control method of the laundry treatment device described in this embodiment and the above embodiment is that, after the step S4, the following steps are also included:

[0072] A1. When the speed of the inner barrel is increased to the maximum speed, the control system issues instructions to detect the vibration values x2 and z2 in the x direction and z direction;

[0073] A2. The control system compares x2 and z2 with preset values m2 and n2 respectively;

[0074] If x2n2, or x2>m2, z2

[0075] If x2

[0076] If x2>m2, z2>n2, execute step A3;

[0077] A3. The speed of the inner barrel drops to the first speed;

[0078] A4. The inner barrel maintains the highest speed until the program is terminated.

[0079] Preferably, the control system executes step S2 after step A3.

[0080] Through the above design, the clothing processing device can realize t...

Embodiment 3

[0083] This embodiment introduces a clothes treatment device according to the dehydration control method of the clothes treatment device in the above-mentioned embodiments, the detection is completed by an acceleration vibration sensor, preferably, the acceleration vibration sensor is a three-axis or multi-axis sensor; The vibration value is the vibration acceleration. The acceleration vibration sensor is arranged on the outer tub, and the inner tub is rotatably arranged in the outer tub; preferably, the acceleration vibration sensor is arranged outside the outer tub. Setting the vibration sensor at this position can measure the vibration state more accurately and in time.

[0084] The dehydration control method of the clothes treatment device introduced in the present invention can detect and judge the vibration state of the inner tub at different dehydration speeds, and make the next step and more accurate judgment according to different vibration states, so that the clothes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com